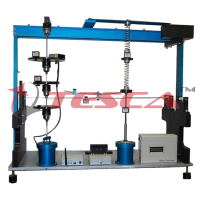

Strut Buckling Apparatus With DAQ

Order Code: 32183

Category: Strength of Materials Lab

Features Buckling is a phenomenon of structural instability that is generally suffered by slender structures under compression. A perturbing force acts over them and causes a failure on them before reaching the critical compressive stress. Tesca St...

SPECIFICATION

Features

Buckling is a phenomenon of structural instability that is generally suffered by slender structures under compression. A perturbing force acts over them and causes a failure on them before reaching the critical compressive stress.

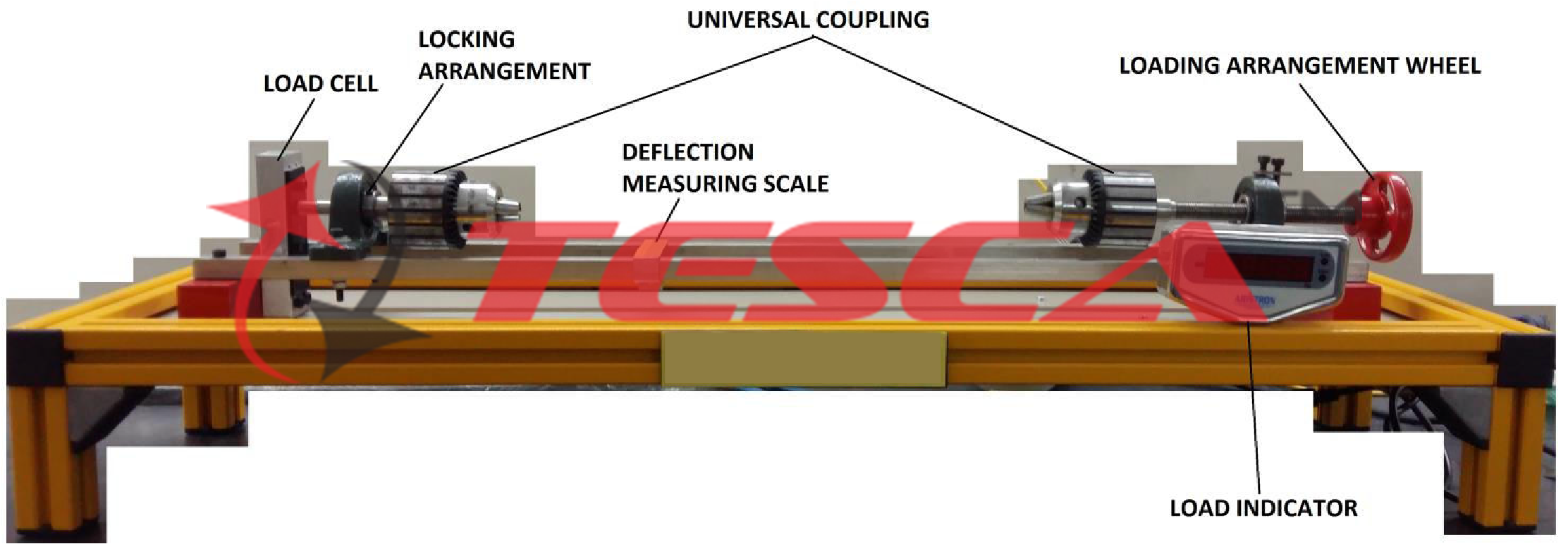

Tesca Strut Buckling Apparatus is an apparatus, to demonstrate the buckling of structures under compression.

Tesca Strut Buckling Apparatus allows the student to obtain experimentally the buckling critical load of slender struts subjected to compression.

The unit allows to study the buckling of pieces of different lengths, ranging from 300 mm. to 625 mm., to which different support conditions can be applied:

Pin-joined end conditions.

Rigidly fixed end conditions.

One end pinned and the other fixed.

To carry out the practical exercises correctly, it is very important to apply the force with only axial component. For that purpose, it has a differential Tesca Strut Buckling Apparatus screw placed at one end, which allows the system compression.

To measure the compression force exerted on the structure, there is a system composed of an elastic ring whose deformation is measured.

The compression force will be directly proportional to the deformation registered in a dial gauge.

Specifications

This unit is mounted on a frame made of anodized aluminum profiles and painted steel panel and supports.

The unit basically consists of:

2 Guides to slide the movable clamp, made of stainless steel, that allow to test pieces up to 650 mm long.

Universal supports to fasten the test piece, according to the required end conditions.

Movable clamp located at one end. It has a crank to adjust the test piece to the desired length.

Besides, it has a system to measure the applied force, by measuring the deformation of an elastic ring.

The clamp can be placed in pinned end or fixed end position, according to the desired practical exercise.

Fixed clamp, which has several functions. The knob has two positions according to the desired end conditions for the clamp. Other function is the system to apply the force to the test piece, consisting of a crank, that compress the structure when it is turned to the right.

Differential screw to allow the system compression.

Dial gauge, with a measuring range of 0-5mm or 0-13mm and accuracy of 0.01 mm to determine the compression load to which the test piece is subjected to.

Load Cell Capacity: 500N

Nine test pieces of different length are included. They are made of tempered steel and their dimensions are 20 - 25mm width and 1.5 mm. thickness:

Test piece 300 mm. long.

Test piece 350 mm. long.

Test piece 400 mm. long.

Test piece 450 mm. long.

Test piece 500 mm. long.

Test piece 550 mm. long.

Test piece 600 mm. long.

Test piece 615 mm. long.

Test piece 625 mm. long.

External Frame Capacity: @5kN

External frame dimensions @ 1000mm x 1200mm

Manuals: This unit is supplied with the following manuals: Required Services, Assembly and Installation, Starting-up, Safety, Maintenance and Practices Manuals.

Experiment Possibilities

1. Study of deformation in beams.

2. Demonstration of the Euler theory for beams.

3. Determination of the relationship between buckling load and slenderness modulus for axial loads.

4. Determination of the critical buckling load of a flat test piece, pinned at both ends.

5. Determination of the critical buckling load of a flat test piece, with one fixed end and one pinned end.

6. Determination of the critical buckling load of a flat test piece with both ends fixed.

91-9829132777

91-9829132777