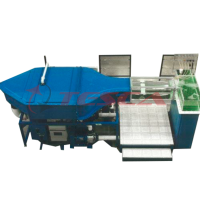

Water Treatment & Conditioning Plant

Order Code: 32479

Category: Environmental Trainers

Tesca Water Treatment & Conditioning Plant 32479 is designed to perform practical experiments of water conditioning. The realization of this equipment allows the treatment up to 170 litres of polluted water. The plant is very flexible and can be ...

SPECIFICATION

Tesca Water Treatment & Conditioning Plant 32479 is designed to perform practical experiments of water conditioning. The realization of this equipment allows the treatment up to 170 litres of polluted water. The plant is very flexible and can be used for the treatment of water containing different kinds of pollutant substances.

The quantity of pollutant substances can vary within the values that are normally shown in the industrial wastewaters.

The industrial wastewaters can be split into first classification, into the ones containing organic products, determining a decrease of oxygen dissolved in the rivers where they flow and into wastes containing inorganic products whose toxicity is typical of the dissolved compounds. Other classification is of pollution are caused by sedimentary and suspension substances.

The unit is supplied with manuals, which describe all parts of the plant, the installation and utilization procedures, as well as many exercises with the relative results.

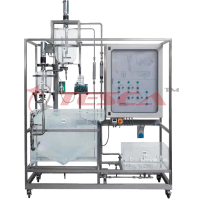

Composition

- 170 litres tank for mixture preparation made of brilliant transparent plexiglas, with grading and stirrer.

- 23 litres tank for oxidant or reducer made of brilliant transparent plexiglas with grading.

- 23 litres tank for acid or base made of brilliant transparent plexiglas with grading.

- 23 litres tank for oxidation or reduction made of brilliant transparent plexiglas with stirrer.

- 70 litres decantation tank type DORR made of brilliant transparent plexiglas with stirrer.

- 23 litres tank for neutralization made of brilliant transparent plexiglas with stirrer.

- Stainless steel wheeled frame.

- Electric drive and control board.

- Board unit for pH control (pHmeter).

- Board unit for the rH control (rHmeter).

- Stainless steel stirrer 100 rpm.

- Stainless steel stirrer with scrapper blades 2 rpm.

- Circuit valves for regulation and cut-off.

- Solenoid valves for the control of pH and rH actuated by controllers.

Description

In the tank (1) it is prepared the water for the treatment to which have been added the pollutant substances planned for the experiments. Through the regulator valve (7), the water is sent to the oxidation or reduction tank (4) to which the reagent is introduced through the opening of the valve (8) that is regulated by the rHmeter. Successively the water goes to the precipitation tank (6) to which is added the neutralizer agent contained in the tank (3), whose dose is regulated by the pH regulator meter which works or the regulator valve (9).

In the tank (6) it may be added a flocculating element in order to activate the precipitation.

At last the water reaches the decantation tank (5) and while from the top is coming out the purified water that will go to discharge, from the bottom and through the regulator valve(10) the sediments come out.

Besides, it is designed a by-pass that allows to pass direct from the tank (1) to the tank (6).

Optional

Automatic Data Acquisition System

The Data Acquisition System enables to collect and analyze, in real time, data from the IC14D Industrial Water Conditioning Pilot Plant, through a Personal Computer. So it allows to monitor the plant and it is a useful tool to perform the necessary experiments.

Composition

Signal Conditioning and A/D Conversion Unit.

Acquisition and Analysis Software for MS-Windows.

Description

The instruments for pH and rH measurements, mounted on the unit, are fitted with analog output for the A/D conversion.

Signal Conditioning and A/D Conversion Unit

The unit allows the conversion of the signals supplied to standard signals, suitable for the A/D conversion card. The A/D conversion card operates on 12 bit with a sampling frequency of about 10 kHz.

The unit can be connected to an IBM or compatible Personal Computer through the serial RS-232 port.

Acquisition and Analysis Software

The Acquisition and Analysis Software operates under MS-Windows and allows to capture data from the transducers located on the plant and to calculate other parameters from the acquired data.

So it is possible to monitor the plant by displaying on the PC screen, in real time, the acquired or calculated parameters and to manage alarm signals, when a parameter goes out of range.

The software allows to display on the screen or to print the diagrams of the acquired data as a function of time and the diagrams required in the exercises.

Acquired and calculated data can be saved onto disk in ASCII format.

Besides it is possible to carry out simulations by introducing data through the keyboard.

Experiments

- Calibration of the rH transmitter/indicator (rH-meter).

- Use of rH regulator.

- Choice of the quantity to be controlled by the rH regulator.

- Calibration of the pH transmitter/indicator (pH-meter).

- Maintenance of pH-meter and rH-meter.

- Depuration of polluted waters.

- Influence of the kind of poly-electrolite in the floccu!ation process.

- Influence of pH in the flocculation process.

- Influence of poly-electrolite quantity in the flocculation process.

- Influence of dilution rate of poly-electrolite in the flocculation process.

- Influence of contemporary variation of the type of poly-electrolite and pH in the flocculation process.

- Determination of pollutants.

- Determination ot substances/sediments.

Required PC configuration

- IBM PC or compatible min. Pentium with Hard Disk (>1Gb), SVGA graphic card 800x600, Mouse, RAM 32 MB min., one RS232 serial port available.

- Graphic Printer.

- MS-Windows ver. 98 or latest versions.

Required services

Main supply: 220/240 V sing/e-phase - 50/60 Hz, 0.5 kW

Water supply: full charge capacity 200 lts

Water drain: rubber carrier 1 1/4”.

Weight and dimensions

Dimensions: 1300x940x2230 h mm

Weights: net 176 kg - gross 360 kg

91-9829132777

91-9829132777