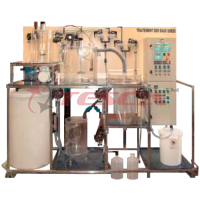

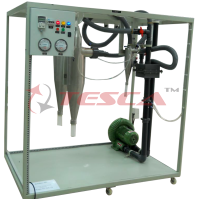

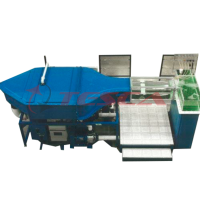

Automated Pilot Plant with Filter Press and Micro-filter

Order Code: 32484

Category: Environmental Trainers

Tesca Automated Pilot Plant with Filter Press and Micro-filter 32484 is provided with a filter press and a microfilter (tangential filtration) that are fed by a screw pump connected with a tank filled with the solution to be filtered. Then filtrate i...

SPECIFICATION

Tesca Automated Pilot Plant with Filter Press and Micro-filter 32484 is provided with a filter press and a microfilter (tangential filtration) that are fed by a screw pump connected with a tank filled with the solution to be filtered. Then filtrate is collected into another tank.

A microprocessor PID controller enables to operate at constant pressure or flow rate.

Process control, data acquisition and supervision are automatically carried out by a microprocessor controller and by a specific control and supervision software that enables the remote control of various operational parameters.

Specifications

- Framework of AISI 304 stainless steel with castors

- Feed tank of AISI 304 stainless steel with capacity of 100 l, including stirring system with submersible pump

- Tank of AISI 304 stainless steel for the collection of filtered water with capacity of 100 l

- Feed screw pump with electronic-inverter control system

- Magnetic-induction flowmeter of stainless steel, with 4 to 20 mA output signal,

- 3 electronic pressure transmitters of stainless steel, with 4 to 20 mA output signal

- 2 safety pressure switches

- Filter press of AISI 304 stainless steel with frames of transparent Plexiglas/acrylic

- Microfilter with housing of stainless steel AISI 316

- Electronic turbidimeter with output of 4 to 20 mA

- Digital microprocessor PID controller

- Connecting lines and valves of AISI 304 and 316 stainless steel

- Emergency pushbutton

- Supervision software for Windows: it enables to control ON-OFF signals, analog signals coming from PID

- controller, real-time trend and historical trend

Experiments

The process unit enables to develop and analyze the following issues:

- Dead end filtration (filter press)

- Tangential filtration (microfilter)

- Characteristic equations of filtration

- Filtration at constant flow rate or pressure

- Displaying the operational parameters of the plant on a schematic diagram with data updating in real time

- Automatic PID control of flow rate and pressure

- Plant supervision

Mains Power

220 – 240V 1Ph, 50Hz

91-9829132777

91-9829132777