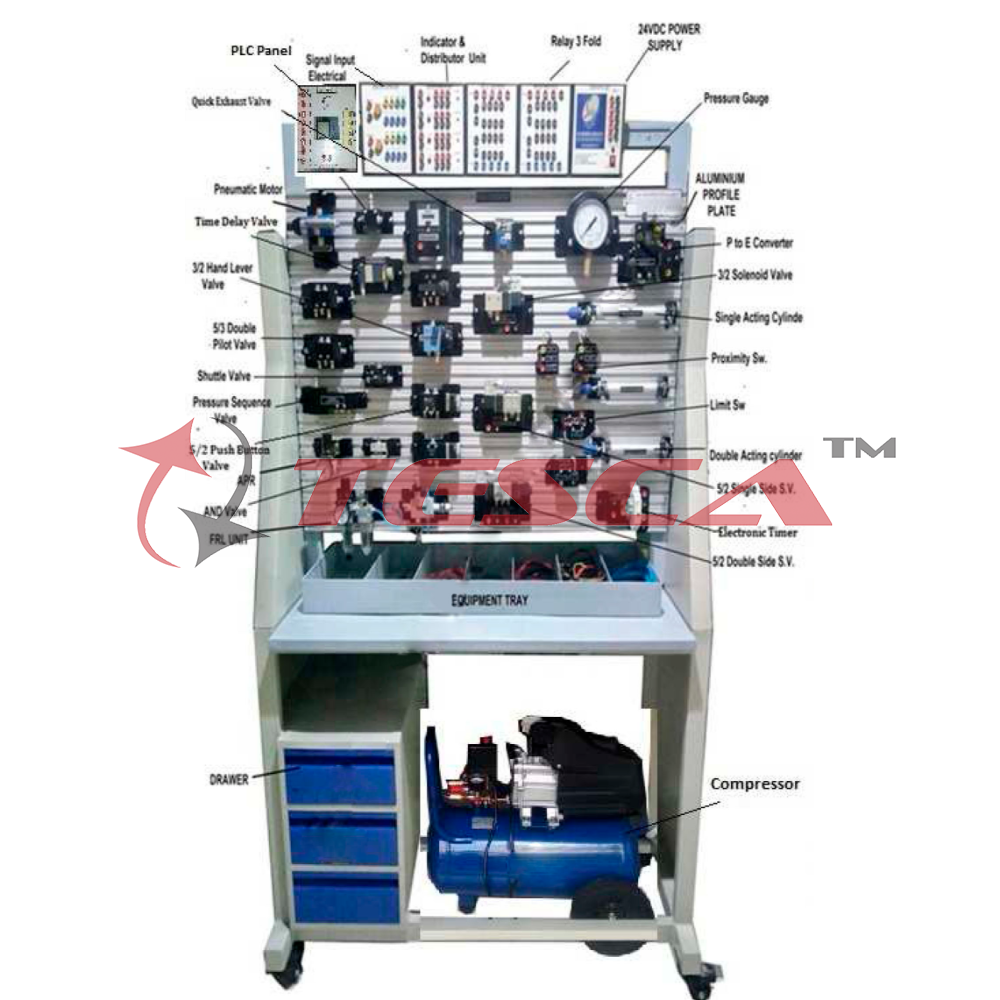

Advanced customized Electro-pneumatic Trainer

Order Code: 52267

Category: Pneumatic Trainers

Features Function & identification of Electro-pneumatic components & their symbols. Direct and indirect manual controls, stroke dependant controls, time dep ndant and pressure dependant controls with tim e delay, pressure sequen...

SPECIFICATION

Features

- Function & identification of Electro-pneumatic components & their symbols.

- Direct and indirect manual controls, stroke dependant controls, time dep ndant and pressure dependant controls with tim e delay, pressure sequence valves.

- Design & function of a electro-pneumatic System.

- Functional diagrams.

- Logic AND/OR function to start signals.

- Application and fault findings of Electro Pneumatic controls.

- Pneumatic power section – Electric control section.

- To empower students to design their own circuits.

- The kit is modular and upgra deable.

- Training literature – Instruct ion & operation manual , troubleshooting & maintenance tips will be provided in soft copy as well as hard copy format

Objectives

- The components are capable of being mounted on an appropriate profile plate with grooves for secure and flexible positioning so that the components can be clamped firmly, quickly and safely through quick fix adaptors. Industrial components are used in the kit so that the students get hands on practical training in using industrial components.

Experiments

- Study of Advanced Electro – Pneumatic Trainer.

- Study of Self Reciprocation of Single Acting Cylinder by Using Electric Limit Switch & 3/2 Solenoid Valve

- Study of Self Reciprocation of Double Acting Cylinder by Using Proximity Switch & 5/2 Double Sided S.V.

- Study of Self Reciprocation of Double Acting Cylinder by Using Proximity Switches & 5/2 Single Sided S.V.

- Study of AND Valve (Dual Pressure Valve)

- Study of Shuttle Valve (OR Valve) Study of Quick Exhaust Valve

- Study of operation of Hand Lever Valve (3/2 & 5/2 DCV) Study of operation Of 5/2 Push Button Valve

- Study of operation Of 3/2 Single Pilot Operated Valve Study of Pressure Sequence Valve

- Study of Flow Control Valve & Pneumatic Motor Study of P To E Converter

- Study of using Signal Input Electrical Box , Relay Three Fold, Indicator & Distributor Unit

- Study of Pneumatic & Electro-Pneumatic Circuits.

- Study of PLC Based cylinder position sensing & Actuation of Solenoid Valves (Optional)

- Study of Time Delay Valve

- Study of Electronic Timer (Optional)

- Study of Operation of Pneumatic Simulation Software (SCADA) (Optional)

91-9829132777

91-9829132777