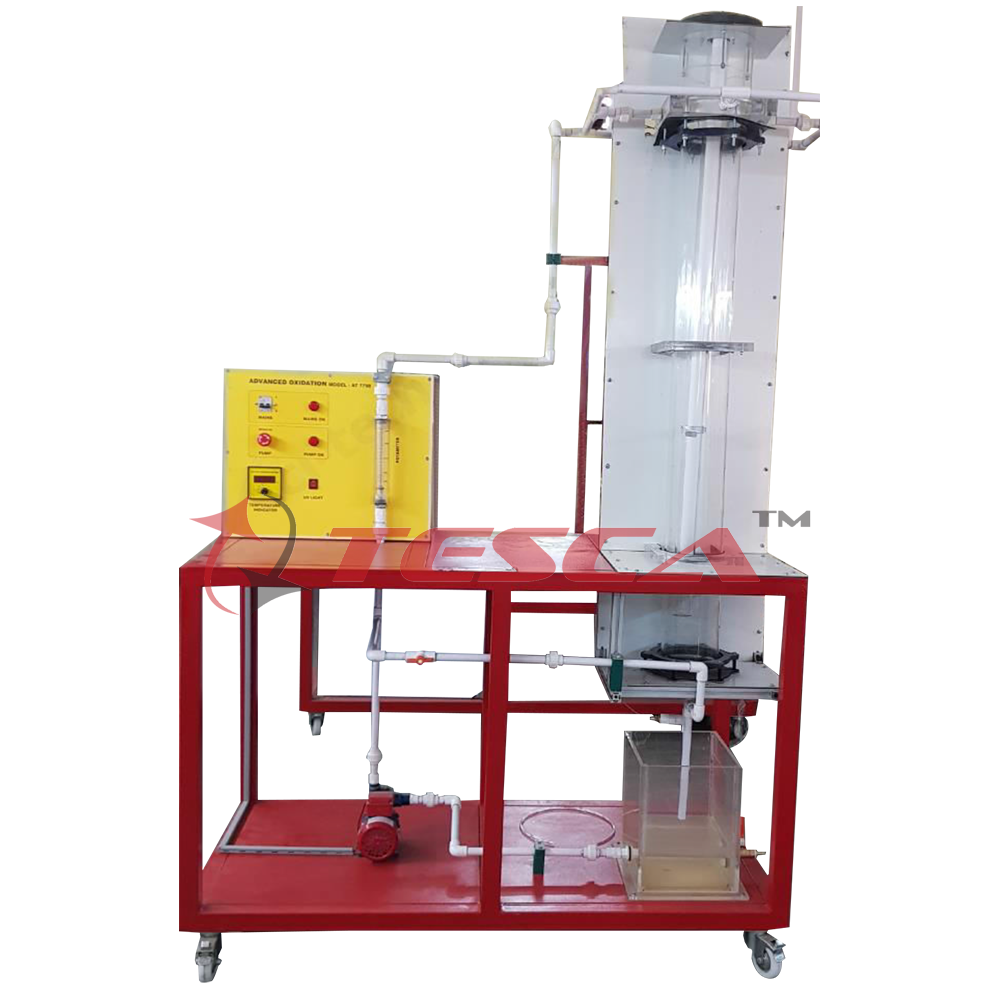

Advanced Oxidation Process

Order Code: 32372

Category: Thermodynamics Lab

Features Oxidation of organic substances with hydrogen peroxide (H2O2) and UV light Discontinuous operation with falling film reactor In water treatment oxidation processes are used to remove organic substances which are not biodegradable. If th...

SPECIFICATION

Features

Oxidation of organic substances with hydrogen peroxide (H2O2) and UV light

Discontinuous operation with falling film reactor

In water treatment oxidation processes are used to remove organic substances which are not biodegradable. If the oxidation is by hydroxyl radicals (OH radicals) it is called “advanced oxidation”. A common method for forming hydroxyl radicals is the irradiation of hydrogen peroxide with UV light.

Tesca Advanced Oxidation Process Apparatus 32372 demonstrates this process using a discontinuous falling film reactor.

The falling film reactor consists of a transparent tube which is open at the bottom. At the top of the tube there is a circular channel. Using a pump the raw water enriched with hydrogen peroxide is transported from a tank into the channel. From here the water flows as a thin falling film along the inside wall of the tube back into the tank. This creates a closed water circuit. At the centre of the tube there is a UV lamp.

By irradiation of the falling raw water with UV light hydroxyl radicals form from the hydrogen peroxide molecules. The hydroxyl radicals oxidate the organic non-biodegradable substances in the raw water. As protection against the radiation the UV lamp is fitted with a protective tube.

The flow rate and temperature of the water are continuously measured. The temperature is indicated digitally in the switch cabinet. Samples can be taken at the tank.

E.g. triethylene glycol dimethyl ether can be used to produce the raw water. Analysis technology is required to evaluate the experiments.

Oxidation phenol destruction performance and bio availability for secondary biological treatment.

Specifications

1. Advanced oxidation process

2. Use of hydrogen peroxide and UV light

3. Formation of hydroxyl radicals (OH radicals)

4. Falling film reactor with UV lamp

5. Discontinuous operation

6. Flow rate adjustable

7. Measurement of temperature and flow rate

8. Digital temperature indication

9. Protection device against UV radiation

Technical Specifications

Falling film reactor (tube)

Diameter : 130mm

Height : 1000mm

UV lamp

Control Panel

Optional Open Control, Multi-control and Real Time Control.

This unit allows intrinsically and/or extrinsically to change the span, gains; proportional, integral, derivate parameters; etc, in real time.

The Computer Control System with SCADA allows a real industrial simulation.

This unit can be used for doing applied research.

This unit can be used for giving training courses to Industries even to other Technical Education Institutions.

Control of the SCADA unit process through the control interface box without the computer.

Visualization of all the sensors values used in the SCADA unit process.

By using PLC-PID additional 19 more exercises

Emitted wavelength : 254nm

Power : 120W

Pump

Max. Flow rate : 360L/h

Max. Head : 9m

Tank

Capacity : 10L

Measuring ranges

Falling Film Reactor

can be done.

Several other exercises can be done and designed by the user.

Requirements

Mains Power 220 – 240V @ 50Hz, 1Ph

- Optional: Computer interface, DAQ/SCADA/

PLC-PID software.

Experiments

Study of advanced oxidation process for wastewater treatment.

Study of advanced oxidation with hydrogen peroxide and UV light.

Influence of the amount of hydrogen peroxide in the oxidation process.

Analysis of the reaction kinetics.

Additional practical possibilities:

91-9829132777

91-9829132777