Gas Adsorption Column

Order Code: 32321

Category: Thermodynamics Lab

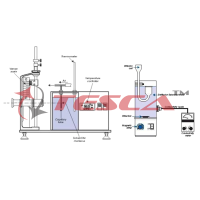

Features: Tesca Gas Adsorption Column is designed to demonstrate & analyse principle of gas adsorption in unit operation of chemical engineering. The gas adsorption unit works by continuously passing a gas mixture through a fixed bed of porous s...

SPECIFICATION

Features:

Tesca Gas Adsorption Column is designed to demonstrate & analyse principle of gas adsorption in unit operation of chemical engineering. The gas adsorption unit works by continuously passing a gas mixture through a fixed bed of porous solid materials known as absorbents. Adsorption takes place primarily on the walls of the pores or at specific sites inside the porous particles. Separation occurs due to differences in molecular weight, shape or polarity causing some molecules to be held more strongly on the surface than others because the pores are too small to admit larger molecules.

The system is fully instrumented with oxygen composition, temperature sensors, pressure gauges & flow meters.

Technical Specifications:

Adsorption Column:

Construction: Stainless Steel jacketed column with packing holder

Column temperature control: Jacketed heater with digital temperature controller

Temperature Range: Max. 250 Deg C

Temperature Measurement: 3 Thermocouples on each column

Flow sensor for supply stream: 0-60 LPM

Compressor with pressure / flow regulator: 0-5 bar, 0-50 LPM

Adsorbent packing for both the columns

Vacuum Pump Range: Down to 0.05 bar

Vacuum Pump accessories: Filter dryer & transducer

Pressure Display: Digital Display

Gas Composition Measurement: 4 x Oxygen Composition Sensors

Gas Composition Display: Digital Display Meter 0- 100 %

Electronic switch over solenoids with toggle control – 4 Nos.

Stainless Steel piping & fitting with control valves.

Experimental Capabilities

Determination of adsorption isotherm equilibrium.

Adsorption isotherm profile characteristic.

Determination of adsorption bed capacity.

To study effect of pressure, flow rate & temperature control on adsorption characteristics.

Mass transfer rates & coefficient.

Effect of adsorption material properties.

Determination of desorption or regeneration process

McCabe –Thiele operation theory

Adsorber design modelling

Required Services

Electric Supply 230 V AC, Single Phase, 50 Hz.

Floor Space: 4 m x 2 m

The unit comes complete with two packed columns, a bottom cooler, a feed vessel and a circulation pump. One absorption column is designed to absorb CO2 from an air/CO2 mixture in to water flowing down the column. The second column of exact dimensions is designed to desorb CO2 from the water product from 1st column into supplied air.

All electronic components are fitted on the main control console for ease of operation and console. The flow connections are fitted with full stainless steel piping and control valves for configuration control.

91-9829132777

91-9829132777