Complete Training System for PLC Fundamentals and Programming Concepts, Including SCADA and HMI, Industrial Networks

Order Code: 22235521.2.20

Category: General Lab Equipment I

Complete system for capacitive proximity switches training. The experiments are carried out using a computed based trainer with hardware and software covering the following topics: Topics (33 different processes) Mask M1 Logic Basic Fu...

SPECIFICATION

Complete system for capacitive proximity switches training. The experiments are carried out using a computed based trainer with hardware and software covering the following topics:

Topics (33 different processes)

- Mask M1 Logic Basic Functions

- Mask M2 Digital Functional Modules

- Mask M3 Motor ON/OFF

- Mask M4 Reversing Contactor

- Mask M5 Star-delta Circuit

- Mask M6 Star-delta Reversing Circuit

- Mask M7 Reciprocating Table Control

- Mask M8 Dahlander Circuit

- Mask M9 DS-Motor with 2 Coils

- Mask M10 DS-Motor Self-starter

- Mask M11 Conveyor Belt System

- Mask M12 Reactive Current Compensation

- Mask M13 Heating Control

- Mask M14 Running Light

- Mask M15 Filling Machine

- Mask M16 Tank System

- Mask M17 Coal Mill

- Mask M18 Embossing Machine

- Mask M19 Ventilator Control

- Mask M20 Construction Site Light Signalling System

- Mask M21 Light signalling system

- Mask M22 Collective Transport Conveyor

- Mask M23 Conveyor Belt Feeding System

- Mask M40 Silo Control

- Mask M41 Reactor

- Mask M42 Load Lift

- Mask M43 Pump Control

- Mask M44 Wastewater Pump System

- Mask M45 Monitoring of 3 Pumps

- Mask M46 Pump System (Pressure)

- Mask M47 Drinks Machine

- Mask M48 Mixing System

- Mask M49 Process Control

The experiment must be complete, with all necessary hardware, software, experimental and device manuals and accessories to perform the experiments.

The experiment set must have a manual accessible via QR Code through an online portal for the management of experiments and devices that allows overview of the total inventory of the educational resource collection, e.g. with number, article name, inventory number, storage location; overview of all experiments possible with the collection of educational materials or a special device; installation and management of the individual storage structure such as premises, cabinets, shelves and trays, also with deposited images; inventory of the complete teaching material collection with indication of the storage location; inventory of device sets, which in turn consist of several individual devices; inventory also using internal school inventory numbers or with individual barcodes, also for distinguishing identically constructed devices. Inventory also indicating the availability of a device, e.g. available, borrowed, defective; generation of individual barcodes for label printing; support of standard barcode scanners, tablets and smartphones for automated access to devices; administration also of own articles or articles of foreign manufacturers, including description, pictures, documents, media and comments; import of existing inventory lists; access to instruction sheets, experiment descriptions, safety data sheets and other media - expandable with your own documents; creation and documentation of own experiments with corresponding hints, pictures and comments; creation and export of inventory lists with indication of number, article name, storage location, status, inventory numbers and comments, e.g. in Excel or LibreOffice; creation and export of experiment lists, which are feasible with the collection of teaching aids taking into account the availability of the individual devices, e.g. in Excel or LibreOffice; creation of the device lists of an experiment with the indication of number, article description and storage location, e.g. as PDF for printout; creation of an up-to-date list of hazardous substances with designation, danger symbols and storage location of the hazardous substance.

Each system must be composed minimally by the following components:

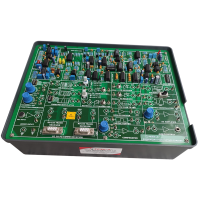

1x Simatic CPU 1512C-1 PN+DP Trainer Package

Consisting of the PLC base unit and the trainer package consisting of profile rail, power supply, CPU module, digital input, Digitala output, analog input, analog output, DP comunication module, Ethernet connection cable and software package TIA - Portal.

Technical specifications:PLC basic unit:

- 24 digital inputs including 16 with tactile detent switch; 16 digital outputs are directly accessible via 4mm safety sockets.

- 32 digital inputs and 32 digital outputs via 4 25-pin connector with occupancy for MCS accessible.

- 2 analog input channels and 2 analog Ausganskanäle accessible via 4mm safety sockets.Power supply:

Input: 1-Phase AC Supply Voltage

- 1 at AC 120 V nominal value

- 2 at AC 230 V nominal value

- Rated line frequency 50 ... 60 Hz Input current

- at nominal level of the input voltage 120 V 3.7 A

- at nominal level of the input voltage 230 V 1.7 ACPU:

CPU 1512C-1 PN

- Display Screen size 3.45 cm

- Controls Number of keys 6

- Mode switch 11. Interface

Ports 2: RJ 45 (Ethernet) Integrated switch2. Interface

Ports 1: RS 485 Programming

STEP 7 TIA Portal can be configured / mixes Programming Language

LAD, FBD, STL, SCL, GRAPHDigital- analog inputs and outputs:

- Digital input DI 32 X DC24V

- Digital output DQ 32 X DC24V

- Analog input AI 4 X U / I; 1 X R/RTD

- Analog output AQ 2 X U / I

1x HMI

- KTP700 BASIC, Basic Panel, touch screen and tactile keys, 7” touch + key TFT Display 65536 colours, MPI, Profi-bus DP, PROFINET interface software WINCC BASIC V13/STEP 7 BASIC V13.

- Built in a panel, all connections on the back side.

Technical Specifications:

- Resolution: 800 x 480 Pixel

- 8x Number of function keys

- USB Interfaces: 1

- Industrial Ethernet : 1

Accessories:

- 1 Industrial Ethernet-switch 5x 10/100 Mbit/s

- 2 cable CAT 6, crossed 2 x RJ45 connector

- 1x Plant Simulator

- Bunit for system simulator. The inputs and outputs are accessible via 4-mm safety sockets or a 700 mm long 50-pole flat-ribbon cable to a PLC or logic controler over a 50-pole socket.Inputs / outputs

- 12 digital inputs, 12 digital outputs

- 2 analog inputs, 2 analog outputs

- 4 relay contacts NCCControl and indication elements:

- 6 buttons

- 6 toggle switches

- 33 LEDs

- 2 potentiometers for 0 ... 10 V DC

- 1 red bargraph indication with 24 segments

- Digital in and output voltage of 24 V DC

- Analog in and output voltage of 0 ... 10 V DC

- Required power supply: 24 V DC, 0.7 A max.

- Ethernet RJ 45

- USB

1x Set of Process simulation Masks

- Mask M1 Logic basic functions

- Mask M2 Digital function modules

- Mask M3 Motor ON/OFF

- Mask M4 Reversing contactor

- Mask M5 Star-delta connection

- Mask M6 Reversing star-delta connection

- Mask M7 Pendulum table control

- Mask M8 Dahlander circuit

- Mask M9 Motor with 2 windings

- Mask M10 Motor self-starter

- Mask M11 Conveyor belt system

- Mask M12 Reactive-current compensation

- Mask M13 Heating control

- Mask M14 Running light

- Mask M15 Tablets machine

- Mask M16 Tank system

- Mask M17 Coal grinder

- Mask M19 Fan control

- Mask M20 Traffic light for road works

- Mask M21 Traffic lights

- Mask M22 Collecting belt conveyor

- Mask M23 Conveyor charging system

- Mask M18 Embossing machine

- Mask M40 Silo control

- Mask M41 Reactor

- Mask M42 Goods lift

- Mask M43 Pump control

- Mask M44 Dirty-water pump system

- Mask M45 Monitoring of 3 pumps

- Mask M46 Pump system (pressure)

- Mask M47 Drinks machine

- Mask M48 Mixer

- Mask M49 Sequence control

- Transparent folder, 410 mm x 320 mm x 10 mm

91-9829132777

91-9829132777