Control System *Laboratory

Order Code: 23246810.3

Category: General Lab Equipment II

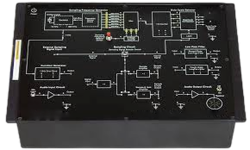

Minimum required didactic content: Distinction between open-loop and closed-loop speed control Design and optimisation of a closed-loop drive control system using all four quadrants Identification of control loop Determination of suitable control par...

SPECIFICATION

Minimum required didactic content: Distinction between open-loop and closed-loop speed control Design and optimisation of a closed-loop drive control system using all four quadrants Identification of control loop Determination of suitable control parameters in time and frequency domains using similar methods to those utilised in practice (Kuhn, Latzel, Ziegler-Nichols, Bode plots) Effect of controller components on the results of the control loop Design and optimisation of cascade control for control of current and speed Includes at least the following DIN A4 modules with the following characteristics: All modules are supplied as a DIN A4 high didactic panel with 4mm secure connection plugs and color printing of wiring diagrams, photos etc. 1x Compact level control kit including vessel, tank, pump and sensors Secondary flow-rate control loop Integrated power amplifier Transparent vessel for observing the height of liquid A second vessel can be connected via quick-release plugs to make a second order control system. Disturbance variables can be simulated by means of adjustable throttle valves Measurement site for pressure sensor in the vessel Pressure sensor to measure height of liquid complete with immersible tube Output voltage: 0 - 10 V Calibration of zero point and gain Additional emergency overflow outlet Reservoir for liquid Operating voltage: +/-15 V DC Nominal current: 1.2 A 1x 4-quadrant drive systems Coupled drive system with two 90-W DC motors Complied 23246810.3 Operation in all four quadrants Tachogenerator and incremental sensor in feedback loop Two highly dynamic 4-quadrant controllers outputting current up to 6 A Built-in current sensors for simple measurement and control of flow Built-in current control for a motor enables well-defined step changes in load Visualisation of various load states Potentiometer for setting load states Built-in wide-range power supply for provision of power 1x Universal digital controller (DSP) Controller topology: two-position, three-position, P, I, D, PID, PII Two independent controllers which can be cascaded or used individually Graphic-capable, backlit display Three soft keys and a function selector wheel for operation parameter setting and configuration PC connection via USB port PC software for parameter setting and visualisation of controller signals using the following virtual instruments: Two-position controller Three-position controller PID controller Cascade controller Step-response plotter Bode plotter Control loop analyser Port for connecting MATLAB (JTAG), 4 Analog inputs with +/-10 V measuring range 2 Analog outputs rated for up to +/-10 V, 2 Digital inputs and 2 digital outputs All inputs and outputs via 4-mm safety sockets, Input for incremental sensor CAN bus interface for expansion of controller, Potentiometer for setting reference voltage 1x DC Power supply, ±15V/6A All accessories necessary for proper operation must be provided, with at least the following: 1x Interactive multimedia courses Interactive experiment setups with animation Measured values and diagrams can be stored in the experiment instructions per drag and drop Direct link to instruments/measurement and test software from the experiment instructions Includes questions with feedback and evaluation logic for progress monitoring Documents can be printed out for hardcopy of experiment instructions including solutions 1x 4mm safety measuring cable set and 19/4mm safety plug set 1x Mobile aluminium experiment stand, 3 levels, 6 x earthed sockets 30-mm table top made of highly compressed, multi-layer chipboard, Resistant to heat and many chemicals Frame with solid impact-resistant protective edging made of 3mm thick RAL 7047 coloured plastic Coating and adhesive are PVC free Power strip with 6 outlet sockets mounted underneath the table top, lead and earthed plug 2 extruded aluminium profiles with multiple grooves 1800 x 120 x 40 mm (WxHxD) 8 equally sized grooves in extruded aluminium profiles (3 on each side and 1 each on the front and back) Table frame made of tough combination of rectangular tubing around the full perimeter PC and Monitor holder 1x digital mutlimeter 1x Standard branded PC with 24'' screen, adapted keyboard, Windows 10 or 11, UPS, spare battery Technical Clauses:

? The bidder must present a manufacturers authorization

? Training manual for the items in form of an interactive software course

? Software packages needed for conducting experiment using these items

? The supplier must provide Minimumu 3 days of training to max. 15 trainers

91-9829132777

91-9829132777