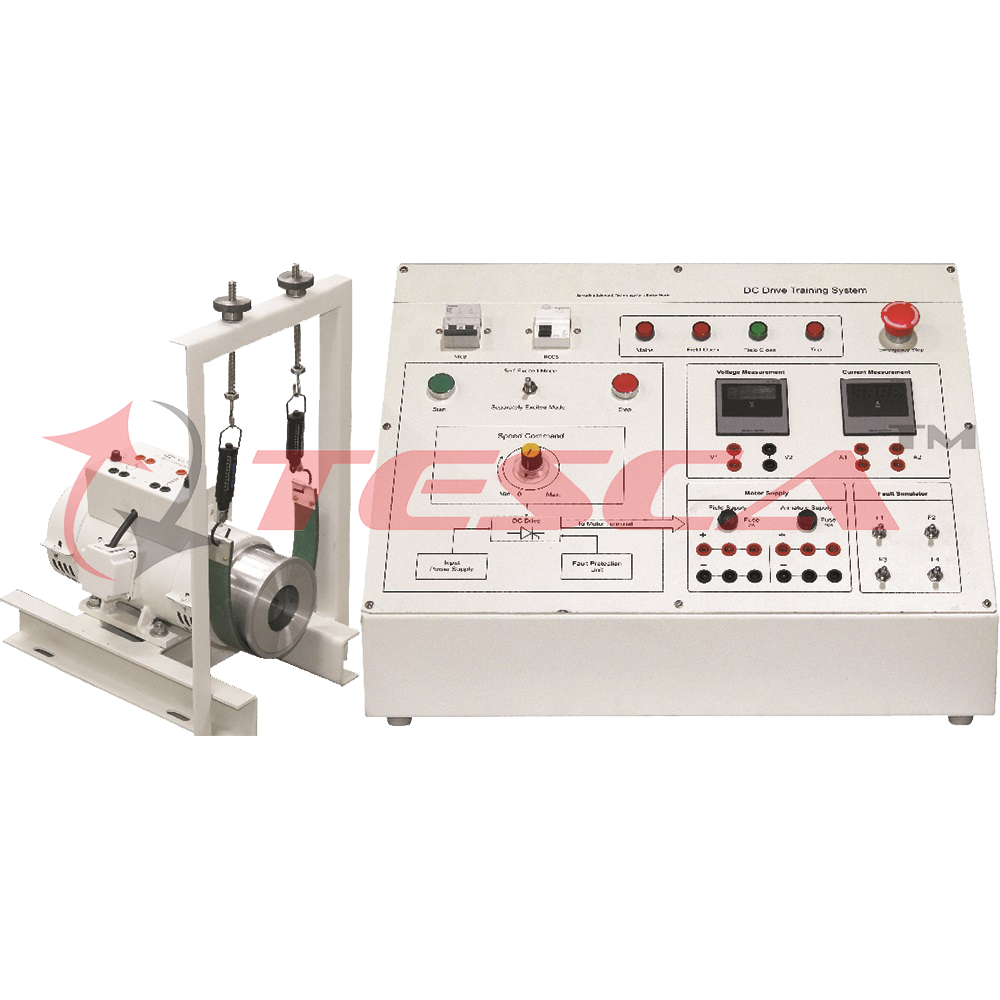

DC Drive Training System

Order Code: 46944

Category: Electrical Machine Lab

46944 DC Drive Training System is used in electrical engineering laboratories for the purpose of conducting experiments in DC machines. This product provides fixed and variable DC output for continuous operation with an over current protection. Outpu...

SPECIFICATION

46944 DC Drive Training System is used in electrical engineering laboratories for the purpose of conducting experiments in DC machines. This product provides fixed and variable DC output for continuous operation with an over current protection. Output voltage and current can be continuously monitored by front panel meters.

46944 includes DC Shunt Motor of suitable mechanical loading arrangement to conduct various experiments such as running & reversing, no load test, load test, etc. It includes study of various faults simulated using toggle switches for trouble shooting of DC drive and circuit.

Features

- Suitable to run in series and shunt mode of machine.

- Low cost thyristor based design.

- Separate section for fixed and variable supply.

- Over current and emergency protection.

- Machine with mechanical loading arrangement.

- Control board consist of high grade FRP material to provide utmost safety to the users.

- Machine with class “B” insulation.

- Brake-Drum/Pulley with heat suppression facility.

- Designed considering all safety standards.

- Diagrammatic representation for the ease of connections.

- Provided with digital tachometer.

Object

- Study of troubleshooting of DC drive using simulated switches.

- Study of self excited & separately excited DC shunt motor.

- Load characteristics of DC shunt motor.

Technical Specifications

- Input mains : 230V AC ±10%, 50Hz

DC output voltage

- Fixed : 220V ±10%, 2A

- Variable : 0-220V ±10%, 12A

DC machine

- Type : Shunt

- Rating : 1 HP

- Voltage rating : 220V ± 10%

- Speed : 1500 rpm ± 7.5%

- Insulation : Class ‘B’

- Loading arrangement : Mechanical

- Brake Drum/Pulley : Aluminum cast

Digital Meters

- Digital voltmeter : 300V

- Digital ammeter : 20A

- Single phase MCB : 16A

- Emergency switch : 10A

- Start and stop push button : 1 no each

- Digital tachometer : 19,999 rpm

91-9829132777

91-9829132777