Determination of Carbon Dioxide In Lime

Order Code: MT214

Category: Cement, Lime Plaster & Mortar Testing

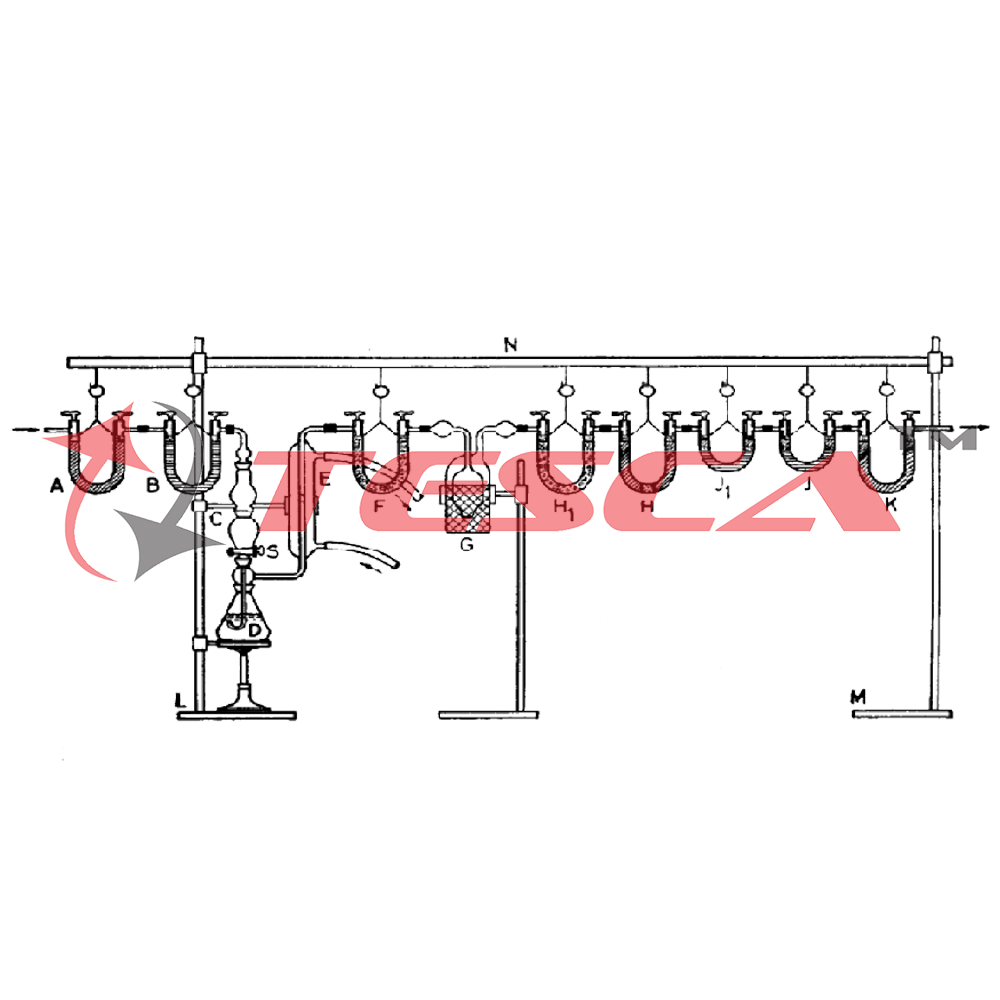

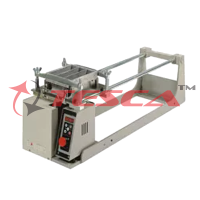

Assembly of apparatus for determination of carbon dioxide in lime: IS 6932-2(1973) standard ( Part II ) covers ‘method of test for determination of carbon dioxide content of building lime. Details: The system consists of a U-tube A wi...

SPECIFICATION

Assembly of apparatus for determination of carbon dioxide in lime:

IS 6932-2(1973) standard ( Part II ) covers ‘method of test for determination of carbon dioxide content of building lime.

Details:

- The system consists of a U-tube A with anhydrous granulated calcium chloride and another U-tube B with soda asbestos, funnel C with a glass stopcock S and a bent inlet glass tube (projecting below the acid level) is used to introduce hydrochloric acid into the generating flask D.

- Condenser E condenses most of the water and hydrochloric acid. The U-tube F contains zinc pallets to react with residual acid, if any acid to absorb moisture. Bubbler G contains concentrated Sulphuric. The U-tube Hr contains pumice stone, impregnated with anhydrous copper Sulphate to remove traces of hydrogen Sulphide.

- Pumice stone is prepared by crushing it to approximately 5 mm size, shifting it free from dust and then transferring 60 g of it to a casserole, it is then covered with a concentrated solution of 30 to 35 g of copper Sulphate and then evaporated to dryness while stirring constantly.

- It is then heated for 3 to 4 hours at 150 to 160`C, cooled in a desiccators and preserved in a glass-stopper bottle. U-tube H contains anhydrous granulated calcium chloride in one limb and anhydrous magnesium perchlorate in the other to remove the last traces of moisture.

- U-tubes J1 and J contain both soda asbestos and anhydrous magnesium perchlorate in each limb to absorb carbon dioxide. U-tube X contains anhydrous granulated calcium chloride and anhydrous magnesium perchlorate in each limb to protect the end of the train against moisture. U-tubes are suspended from a cross bar Jv.

- Two retort stands L and M carry the cross bar N. All joints are made of stout-walled rubber tubing with the ends of the glass tubes touching each other. Means are provided to pass air through the system either under pressure or by suction. Supplied without chemicals, Electronic Balance and distilled water plant.

Chemical required:(optional)

1. Calcium chloride

2. Soda asbestos

3. Zinc pallets

4. Pumice stone

5. Sulfuric acid

6. Copper sulfate

7. Magnesium percolate

8. Hydrochloric acid

91-9829132777

91-9829132777