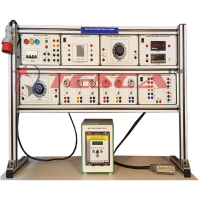

Electrical Machine Trainers

Order Code: 21225107.1

Category: Electrical Machine Lab

Specifications:- DC Motor/ Generator with the facility of Separate/ Compound/Series Excitation (01 No.) Power: Min.300 W Voltage (Armature): Min.220 Vdc Voltage (Separate Excitation): Min.220 Vdc Rpm.: Min.3000 DC motor operation sho...

SPECIFICATION

Specifications:-

DC Motor/ Generator with the facility of Separate/ Compound/Series Excitation (01 No.)

- Power: Min.300 W

- Voltage (Armature): Min.220 Vdc

- Voltage (Separate Excitation): Min.220 Vdc

- Rpm.: Min.3000

- DC motor operation should also be performed by this unit

- Should be IM B3 form of construction

- Should have IP 22 protection

- Should be included with thermal protector in this unit

3- Phase Cage Motor Asynchronous Type (01 No.)

- Power: Min.500 W

- Voltage: Min.230/400V, 50Hz

- Rpm.: Min.2850 for 2 poles

- Should have Delta-star connection

- Should be IM B3 form of construction

- Should have IP 44 protection

- Should be included with thermal protector in this unit

3- Phase Wound Rotor Motor Asynchronous Type (01 No.)

- Power: Min.500 W

- Voltage: Min.230/400V, 50 Hz

- Rpm.: Min.2900 for 2 poles

- Voltage (Rotor): Min.400V

- Should have Delta-star connection

- Should be IM B3 form of construction

- Should have IP 22 protection

- Should be included with thermal protector in this unit

3- Phase Motor/ Generator Synchronous Type with Starting Function Asynchronous Type (01 No.)

- Power: Min.350 VA

- Voltage: Min.230/400V, 50 Hz

- Rpm.: Min.3000 for 2 poles

- Voltage (Excitation): Min.220 Vdc

- Synchronous motor operation should also be performed by this unit

- Should have Delta-star connection

- Should be IM B3 form of construction

- Should have IP 22 protection

- Should be included with thermal protector in this unit

1- Phase Motor Asynchronous Type with Starting Capacitor (01 No.)

- Power: Min.300 W

- Voltage: Min.230V, 50 Hz

- Rpm.: Min.2900 for 2 poles

- Should be IM B3 form of construction

- Should have IP 44 protection

- Should be included with thermal protector in this unit

AC/DC Motor Universal Type (01 No.)

- Power: Min.260/330 W

- Voltage: Min.230 Vac, 50 Hz / 230 Vdc

- Rpm.: 3000

- Should be IM B3 form of construction

- Should have IP 22 protection

- Should be included with thermal protector in this unit

Power Supply Unit Tabletop Type (01 Set)

- For general electric measurements and of measurements on electric machines

- Power Supply: 3ph, Neutral, Protective Earth, 50-60 Hz

Variable Resistive Load (01 No.)

- Should have 3 separate resistive sectors

- Should have 21 values of DC or single-phase active power

- Should have 7 values of three-phase active power

- Should have safety terminals and protection by fuses

- Power supply (AC): Min.230/400V

- Power supply (DC): Min.220V

- Active power: Max.460W

Variable Inductive Load (01 No.)

- Should have 3 separate inductive sectors

- Should have 21 values of single-phase reactive power

- Should have 7 values of three-phase reactive power

- Should have safety terminals and protection by fuses

- Power supply: Min.230/400V, 50 Hz

- Apparent power: Max.460 VA

Variable Capacitive Load (01 No.)

- Should have 3 separate capacitive sectors

- Should have 21 values of single-phase reactive power

- Should have 7 values of three-phase reactive power

- Should have safety terminals and protection by fuses

- Power supply: Min.230/400V, 50 Hz

- Apparent power: Max.460VA

Transformer 1-Phase (01 No.)

- Power: Min.760 VA

- Voltage (primary winding): Min.230V, 50 Hz

- Voltage (secondary winding 1): Min.0-53-200-400V

- Voltage (secondary winding 2): Min.0-115-230V

- Should have IP 22 Protection

- Should be included with thermal protector in this unit

Tachogenerator (01 No.)

- Can be used to measure the speed of rotation of “M” and “M-B” electric machines

- The output signal can be converted into rpm by tachometer voltmeter

- Can be used for DC motor drive in closed-loop Configurations

- Output voltage: Min.0.06 V per revolution

- Rpm.: Max.5000

- Output voltage 1: Min.300 Vdc at 5000 rpm.

- Output voltage 2: Min.10 Vdc at 5000 rpm.

- Should have IP 44 Protection

DC Starting Rheostat Rotor Starting Stator Starting (01 No.)

- Linear rheostat

- Power: Min.3 x 500 W

- Current: Min.3 x 3.16 A

- Resistance value: Min.3 x 50Ω

- Terminals: Min.9

Shunt Field Rheostat Generator (01 No.)

- Linear rheostat

- Power: Min.500W

- Current: Min.0.31A

- Resistance value: Min.5000Ω

- Terminals: Min.3

Shunt Field Rheostat Motor (01 No.)

- Linear rheostat

- Power: Min.500 W

- Current: Min.1.55A

- Resistance value: Min.200Ω

- Terminals: Min.3

Series Field Rheostat Motor (01 No.)

- Linear rheostat

- Power: Min.500 W

- Current: Min.3.16 A

- Resistance value: Min.50Ω

- Terminals: Min.3

Electrical Measurements Modules (01 Set) Set of devices:

- 2 Modules: 1 three-pole power switch

- 1 Module: 1 phase sequence indicator with lamps

- 1 Module: 1 synchronization device for parallel connection of three phase lines or generators

Set of digital instruments:

- 1 Module:1 tachometer Min.240 Vdc @ 4000 RPM Auxiliary power Min.110-240 VAC – 50/60 Hz

- 2 Modules (Each module includes): Current Measurement: Max.5A. Should include 3 CT 5/5A. The range can be expanded with 3 external CT x/5A; THD Total Harmonic Distortion for currents;

- Over current: Min.50A for 1 sec.; Current Accuracy: Min.0.5%

- Voltage Measurement: Min.3-ph + N.; 400 V phase to N and 690 V ph. to phase, 45-66 Hz; Voltage Accuracy: Min.0.5%; THD Total Harmonic Distortion for voltage

- Frequency: Min.45-66 Hz.

- Power Measurement: Min.3.5 kVA / kW / kVAr

- Other parameters measured: Power factor, Voltage Asymmetry, Energies meter: kWh / kVAh / kVArh and Counter Hour

Other features:

- Auxiliary power Min.110-240 VAC – 50/60 Hz

- Graphic LCD display, 128 x 80 pixel, backlit, with 4 grey levels

- Four keys for parameters visualizing and settings

- Possibility to create up to 4 programmable pages, each with 4 selectable measures among the measured parameters.

- Two programmable relays with max/min alarm functions, selectable among the measured parameters

- Graphical Menu and Messages in 5 languages: English, Italian, Spanish, French and Portuguese

- Communication port: RS485 for data networking

- All connections are provided with safety plugs (Ø 4 mm)

Module (Each module includes):

- 2 multifunction instruments, with the following features:

- VDC max.: 600 V; precision: ± 0.2 %

- IDC max.: 20 A; precision: ± 0.5 %; overload 2 x 20 A (3 min)

- Power DC max.: 10 kW

- Displays: visualize V, I, W. LCD, backlit, 3 lines, 4 digit per line

- Automatic decimal point. Five levels of illumination.

- All connections 4 mm Ø safety terminal

Multifunction Measuring Instrument (01 No.)

- Multifunction Instrument in an isolating table-top box;

- Connections from front and sides, with electrical international symbols;

- Power connections should be carried out with 4mm safety terminals;

- Programmable connections with dia. 2mm connectors;

- It should measure 1-phase / 3-phase electrical parameters. More than 300 TRMS parameters, such as: voltages, currents, active, reactive and apparent powers, power factor, frequency, V and I harmonic analysis up to 31° harmonic;

- Measurements of imported/exported total and partial active energy, inductive/capacitive reactive energy, total and partial apparent energy;

- Measurements class for voltages and currents: 0.2% and currents up to 10A;

- Auxiliary power: 110/250VAC, 50/60Hz

- Graphic LCD display, 128 x 80 pixel, backlit with 4 grey levels;

- Four keys for parameters visualizing and settings;

- Possibility to create up to 4 programmable pages, each with 4 selectable measures among the instrument measures;

- It should include a module with 2 relay outputs for local/remote alarms;

Software for Multifunction Measuring Instrument (01 No.)

- The software should allow to visualize the measurements from the instruments as “virtual instruments”

- Sample the user-defined measurements and save them in different formats like MS- Access, ASCII text and MS-Excel

- Trace graphs of the sampled measurements

- Apply alarm limits to the sampled measurements

- Save on disk the alarms and events sequence of the instruments network

- Visualize and modify the instrument set parameters with the possibility of saving them on disk, recall and print the settings

- Visualize a graph of the voltages and currents harmonic content, using the measurements given by the instrument

- Possibility to program up to 4 pages with parameters selected by the user

- Change the menus and commands language of the program

Tabletop Vertical Frame (01 No.):

- Tabletop Vertical Frame for the Modules of Electrical Measurements

Cables (01 Set): Set of 40 Cables

- Safety Terminals, Ø4mm, Different Lengths and Colors

Cable Holder (01 No.)

- Should be lightweight unit made of structural aluminium profile

- The cable should support (both sides) are to be made of plastic grids, so to avoid damaging the cables insulation.

Cabinet (01 No.)

- Cabinet made of SS & Powder Coating

Experiments to be done:

Induction motor

Starting experiment of the 3 phase induction motor

- Y-Δ starting of three phase squirrel cage induction motor

- Forward / Reverse operation of three phase induction motor

- Slip measurement of the three phase induction motor

- Load experiment of the three phase induction motor

- Forward / Reverse operation of the single phase induction motor

- Characteristic experiment of the single induction motor

- Operation of universal motor

- Power factor of the three phase induction motor

- Rotor characteristic of the three phase wound-rotor motor

Synchronous machine

- Non-load experiment of the synchronous generator

- Load experiment of the synchronous generator

- Starting method of the synchronous motor

- Phase and load characteristic experiment of the synchronous generator

DC Motor

- Starting method of the DC shunt motor

- Non-load experiment of the DC shunt generator

- Load experiment of the DC shunt & compound generator

- Load experiment of the DC shunt & compound motor

- Efficiency measurement of DC shunt motor by loss separation method

- Forward / Reverse operation method of DC motor

1 Phase Transformer

- Measuring Coil Resistance of Transformer

- Measuring Coil Resistance of Transformer

- Impedance of TransformerCurrent Ratio and Impedance of Transformer

- Voltage Regulation Curve of Transformer

- Polarity of Transformer

- No-Load & Load Experiment of a 1 Phase Transformer

- Short Experiment of a 1 Phase Transformer

- Parallel Operation of a 1 Phase Transformer

91-9829132777

91-9829132777