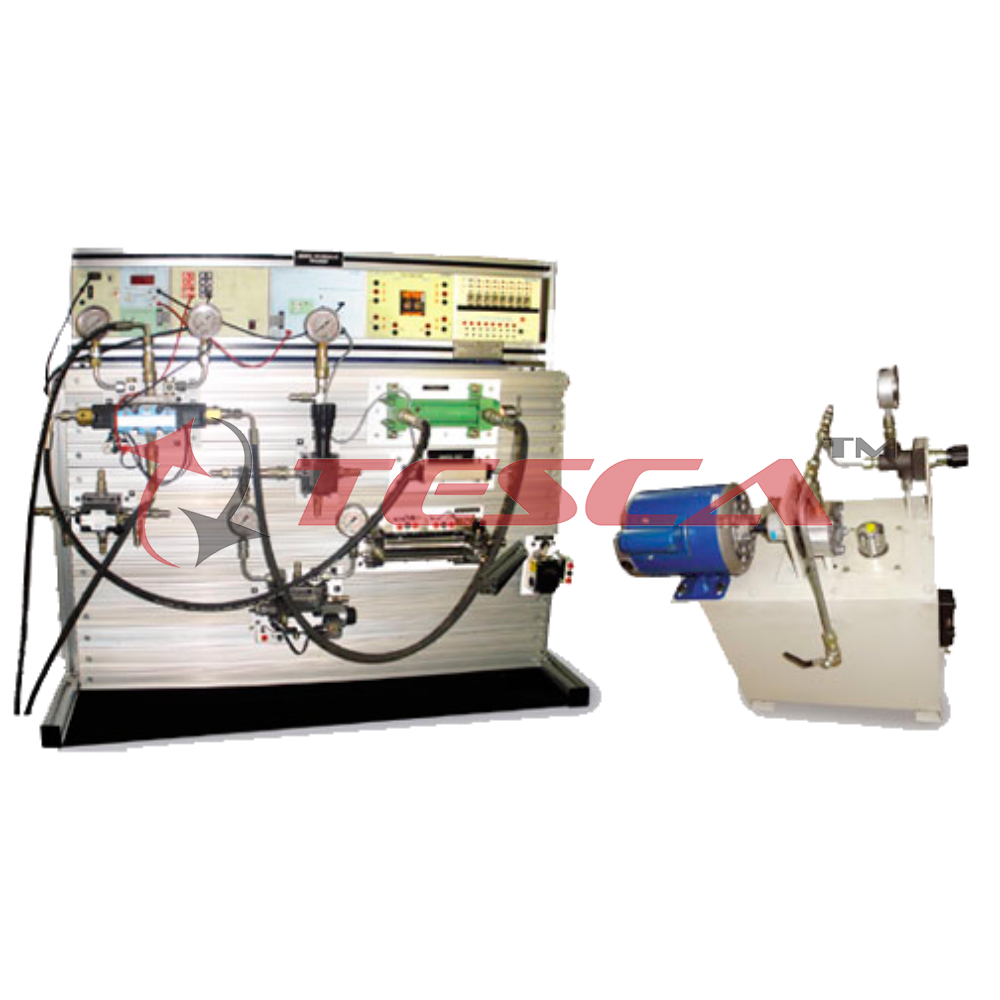

Electro Hydraulic Trainer

Order Code: 52068

Category: Hydraulic Trainers

Features Choice of 2 top models Hydraulic/Electro Hydraulic trainer (Optionally PLC may be supplied.) / Use of aluminium profile grooved plate (CD=25mm) experiment board. Optionally table with drawers (3 nos.) To store compo...

SPECIFICATION

Features

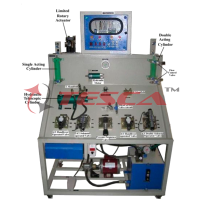

- Choice of 2 top models Hydraulic/Electro Hydraulic trainer (Optionally PLC may be supplied.) / Use of aluminium profile grooved plate (CD=25mm) experiment board. Optionally table with drawers (3 nos.) To store components when not in use & 4 Nos. of caster wheels.

- Qui9ck release socket plug arrangement for building circuits, Lighter pneumatic components are mounted using lever operated mounted adapters for quick release & placement.

- List of components may be modified as per your requirement.

- Top electrical panel row exists in electro hydraulic / Pneumatic only.

Power Generation

Power pack (50 bar) consist of :

Power pack (50 bar) consist of :

- Tank 25Ltr.

- Gear pump 3LPM with ball valve for flow measurement in Beacker (optional),

- Electric motor 0.5 HP 1440 RPM 230vac,

- Oil Breather Oil level indicator, sunction filter / Strainer Return line filter, 70 bar Gage ,

- Relief valve.

Mechanicla Dimension

Anodised sturdy Aluminum profile rack (table top) with groove experiment board (Optibally double sided).

Anodised sturdy Aluminum profile rack (table top) with groove experiment board (Optibally double sided).

Totel dimension : 1165mm (W) X 800mm (H), Aluminum grooved T bolt Board : L = 107 cm, W = 70cm. Height 700mm Reclining at 00, 200,300, . Oil Tray (107 cm A 300 cm X 2cm) power coated MS

NET Weight : 70/75 kg. (Electrohyd), Gross Weight : 85/90kg. (Electrohyd).

Optional Experiments only for Electrohydraulic Trainer

- Servo position control (Close loop) consisting of CIP panel with servo control using relay control circuit ,EMT8 power supply for stroke length display, liner motion (100mm, stroke) potentiometer (5KW) as a position sensor coupled to D. A. cylinder.

- Proportional flow and direction control valve with built in amplifier with ±5V l/P voltage to control flow and direction 5KW servo pot to sense Position coupled to D.A. cyliner, open loop position contron, Emt8 panel to display stroke length.

- Proportional flow and direction control valve with amplifier card & LVDT feedback close

91-9829132777

91-9829132777