Electro Hydraulic Trainer

Order Code: 52068C.1

Category: Hydraulic Trainers

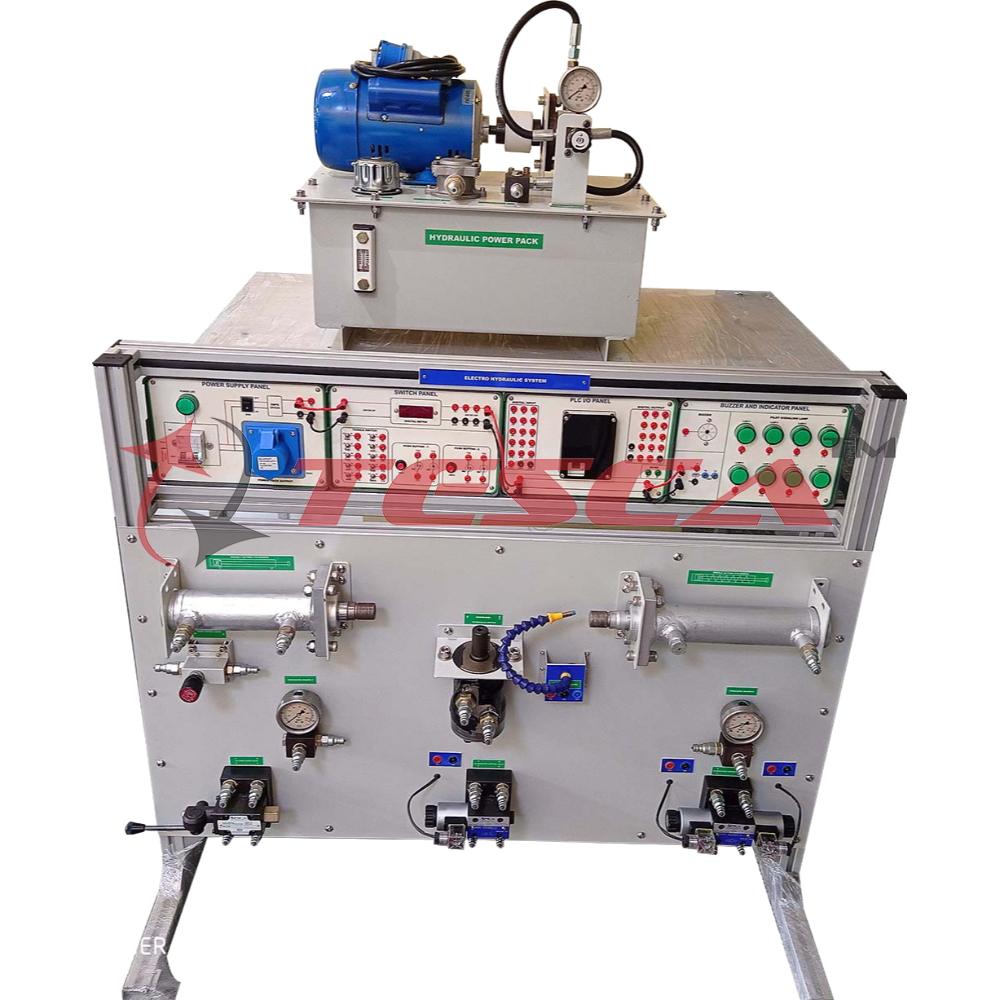

52068C.1 Electro Hydraulic Trainer is designed to demonstrate the design, construction and application of Hydraulic components and circuits. It integrates PLC technology to build hybrid Industrial Automation systems with Hydraulic components and modu...

SPECIFICATION

52068C.1 Electro Hydraulic Trainer is designed to demonstrate the design, construction and application of Hydraulic components and circuits. It integrates PLC technology to build hybrid Industrial Automation systems with Hydraulic components and modules.

Hydraulic technology is found in numerous areas of engineering. Students investigate the basic “building blocks” of modern Hydraulics and how they are interconnected to form systems. Hydraulic Systems provide the power needed to control metal forming machinery, conveyor systems, component test stands, foundries and primary metals plants, presses, including cushions, clutches and brakes, automated assembly systems, packaging systems, pulp and paper industries, material handling, and robotic systems. PLC provides flexibility to design and build numerous systems using software and I/O interfaces without changes to the hard wired connections.

Features

Experiments

Hydraulic technology is found in numerous areas of engineering. Students investigate the basic “building blocks” of modern Hydraulics and how they are interconnected to form systems. Hydraulic Systems provide the power needed to control metal forming machinery, conveyor systems, component test stands, foundries and primary metals plants, presses, including cushions, clutches and brakes, automated assembly systems, packaging systems, pulp and paper industries, material handling, and robotic systems. PLC provides flexibility to design and build numerous systems using software and I/O interfaces without changes to the hard wired connections.

Features

- PLC operated Electro Hydraulic platform

- 12 Digital Inputs, 8 Digital Outputs

- Open platform to explore wide PLC and Hydraulic applications

- Industrial feel & look

- DIN rail mounting for PLC

- Function and identification of Hydraulic components and their symbols

- Powerful instruction sets

- High execution speed

- Extremely easy and student friendly software

- Several sample Ladder programs

- Practice troubleshooting skills

- Extensive Learning

- Workbench has 4 wheels, suitable for movement installation

- Robust construction

- Toggle switches, LEDs, buzzer, double acting cylinder, solenoid valve, flow control valve, manifold, hand lever valve, limit switch, hydraulic motor, single acting cylinder, proximity sensor, power pack

- Board to attached documents

- 4 mm patch cord connections

- Mounting panel for Hydraulic components

- Two storage drawers with telescopic locking facility, place in drawers for meters, patch cords, components, bread board and other accessories for storage, easy identification and access inside the drawers.

- MCB for ON/OFF control and over load protection

- Provision for PC – CPU

- Sequential & linear Hydraulic control

- Understanding of Industrial Hydraulic components

- Hydraulic safety awareness

Experiments

- Study and use the NO (normally open) and NC (normally close) instruction bit.

- Study and implementation of NOT gate using PLC

- Study and implementation of AND gate PLC

- Study and implementation of OR gate PLC

- Study and implementation of NAND gate PLC

- Study and implementation of NOR gate PLC

- Study and implementation of XOR gate PLC

- Study and implementation of XNOR gate PLC

- Study and use of Set and Reset bit

- Study and use of Memory bit

- Study and use of Timer instruction

- Study and use of Counter instruction

- Study and use of Compare instruction

- Study and use of Arithmetic (Addition) instruction

- Study and use of Move instruction

- Control of Double Acting Cylinder_1 (DAC1) using Solenoid Valve_1 (SV1) and PLC

- Control of Single Acting Cylinder (SAC) using Solenoid Valve_2 (SV2) and PLC

- Control of Hydraulic motor using solenoid valve_3 and PLC

- Counting of double acting cylinder_1 piston forward movement using Limit switch and PLC

Technical Specification

- PLC

- Digital Inputs : 12

- Digital Outputs : 8

- Program size (Words) : 2048

- Boolean execution speed : 0.33 ms/Sequential instruction in average

- Interfacing : USB

- No. of ports : 1

- Input Voltage : 24 V DC

- Output Voltage : 24 V DC

- Power Supply : 110V - 260V AC, 50/60Hz

- General

- Toggle Switches : 8 nos.

- Visual Indicators : 8 nos.

- Audio Indicator : 1 no.

- Digital Voltmeter : 1 no.

- Hydraulic Components

- Double Acting Cylinders : 1

- Hand lever valve : 1

- Manifolds : 4

- Flow control Valve : 1

- Solenoid Valves : 3

- Proximity Sensor : 1

- Single Acting Cylinder : 1

- Hydraulic Motor : 1

- Limit Switch : 1

- Oil Hydraulic Power Pack : 1 Capacity 20 Liter with oil

- level indicator, gear pump:

- 2LMP, 20-50bar, Breather

- Valve, Electric Motor 0.5HP,

- 230VAC, Relief Valve

91-9829132777

91-9829132777