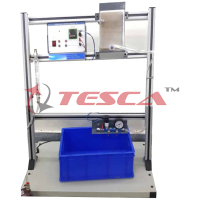

Level Control Trainer (with Ultrasonic Level Transmitter)

Order Code: 52227

Category: Process Control Trainers

The Level Control Trainer is the system, which outlines the basics of Closed Loop Level Control and various aspects related to it. KEY WORDS: Open & close loop response. SCADA Based Level Control MANUAL/AUTO tuning of contr...

SPECIFICATION

The Level Control Trainer is the system, which outlines the basics of Closed Loop Level Control and various aspects related to it.

KEY WORDS:

- Open & close loop response.

- SCADA Based Level Control

- MANUAL/AUTO tuning of controller

- Feedback Level control.

- ON-OFF & PID control.

- P, P I, P I D Controller Action.

- USB/RS232/RS485/Ethernet/ Modbus Communication.

- Transient Response analysis study

- Ability to hook up with DCS (Distributed Control System Trainer)

RANGE OF EXPERIMENTS

- Study of single loop Feedback Proportional (P), Integral (I) and Derivative control (D) actions.

- Study of operation and calibration of transmitters, I/P converter and Control Valve.

- Study of OPEN LOOP/CLOSE LOOP TUNNING & AUTO TUNNING of controller.

- Study of STEP response & Transient response of controller ( process curve).

- Study of tuning and operation of PID controller.

- Study of SCADA Application Software/ Computerized Control of Level Control System.

- Study of stability of single loop Level Control System.

- Configure microcontroller based controller to give manual output, changing controller modes (Manual/Auto), Checking ON-OFF, Proportional, Integral, Derivative, PI and PID control actions, Change local Set point, configure and run a set point ramp, configure measured values to either percentage or Engineering units.

- Study of Communication Protocols and interfacing of System with DCS / SCADA etc.

- Study of SCADA Application Software/ Computerized Control of Level Control System.

FEATURES

- Illustrates the concept of feedback Level control loop.

- User Friendly, Self Explanatory Systems.

- System Frame with Caster Wheel Arr

- Inbuilt Safety Measures to avoid improper usage.

- M.S. powder coated cubical plant with standard Instrument Mountings.

- Computer Interface (Optional), SCADA Application software connectivity for analysis of Level Control System Trainer.

- Training Manual & Mimic Charts for Operation Ease.

- Leak proof Safety Measures, sturdy piping.

91-9829132777

91-9829132777