Transparent Batch Reactor

Order Code: 32329

Category: Thermodynamics Lab

Features Supply unit for various reactors: 32327-32331 Saponification reaction with conductivity measurement to determine the conversion Preheating of the reactants The reactor is the core element of a chemical production facility. In the react...

SPECIFICATION

Features

Supply unit for various reactors: 32327-32331

Saponification reaction with conductivity measurement to determine the conversion

Preheating of the reactants

The reactor is the core element of a chemical production facility. In the reactor, the starting substances (reactants) react with each other to form a new substance (product). The reactor has to guarantee the conditions for an optimal reaction process. This primarily concerns the temperature in the reactor. Different types of reactors are used, depending on the requirements.

Tesca Chemical Reactors Service Unit 32326 serves as a supply unit for six different reactors. The reactor to be examined is mounted onto the supply unit and held by two pins in position. For continuous operation of the reactors, two tanks for the reactants are arranged on the trainer. The supply unit and the reactor are hydraulically connected via hoses. The hoses are equipped with quick-release couplings for easy attachment. Two pumps convey the two reactants into the reactor. The retention time of the reactants in the reactor can be adjusted via the pump speed. In the reactor, the reactants react to form a product. An additional tank and an additional pump for the product is provided.

The supply unit is equipped with a heating water circuit with pump, tank and heater to control the temperature in the reactor. The cold water circuit can be fed from the water chiller. Conductivity and temperature in the reactor are measured with a combined sensor. The switch cabinet contains the necessary controls to start the stirrers in the different reactors. The measured values are digitally displayed on the switch cabinet. Optionally, they can also be transmitted directly to a PC via USB where they can be analyzed with the data acquisition software included in the scope of delivery.

Specifications

Supply unit for 6 different chemical reactor types

Connection of the reactors via hoses with quick-release couplings

Water circuit with tank, 100W heater, temperature controller, pump and low water cut-off for heating and cooling (with water chiller)

Temperature control of the reactants and reactors

3 Glass tanks for reactants and products

5 Peristaltic pumps to deliver the reactants and products

2 Combined sensors for measuring the conductivity and temperature

Optional Tesca software for data acquisition via USB under Windows 7, 8.1, 10

Technical Specifications

Peristaltic pump for reactants

Max. flow rate: approx. 180mL/min

With hose 8,0x4,8mm

Peristaltic pump for products

Max. flow rate: approx. 240mL/min

With hose 8,0x4,8mm

Water pump: Magnetic, for Hot Water

Max. flow rate: 50LPM

Max. head: 5M

Power consumption: 200W

Heater: Water Coiled

Power consumption: 1000W

Tanks

Reactants: 2.5L

Product: 2.5L

Heating water: 10L

Measuring ranges

Conductivity: 0…100mS/cm

Temperature: 0…60°C

Speed of the peristaltic pumps: 1x 0…100min-1

Experiments

In conjunction with a reactor (32327-32331):

Learning the design and operation of different reactor types

Conversion depending on

Reactor type

Retention time in the reactor

Temperature

Concentration

Fundamentals of a saponification reaction

Determination of the retention time distribution

Requirements

Water connection, drainage system

Ethyl acetate, caustic soda (for saponification reaction)

Continuous Stirred Tank Reactor : Order Code - 32327

The continuous stirred tank reactor is probably the most common type of reactor found in industry. The Tesca Continuous Stirred Tank Reactor Model TH 081 is a small scale demonstration version for educational use. It is extremely flexible in use and can be used for both continuous and batch reactions. The volume of the reactor is adjustable between 0.4 and 1.5 litres using an adjustable standpipe, allowing different hold up volumes and residence times to be investigated. The temperature probe and conductivity probe (supplied with the TH-080 Series) can be positioned in the reactor vessel. A stainless steel coil is used for temperature control of the reactor from the hot water supply on the TH-080 Series (or cold water from such as the Tesca Chilled Water Circulating Unit). A variable speed mixer/agitator is included (controlled by the TH-080 Series together with baffles to improve the mixing.

32327 uses the saponification reaction and uses conductivity to measure the progress of the reaction. It also uses a step input change experiment to obtain the residence time distribution.

Demonstration Capabilities

Effect of residence time on conversion

Determination of reaction rate constant

Residence time distribution

Evaluation of empirical rate expressions from experimental data

Effect of temperature on reaction rate

Effect of mixing on reaction rate

Effect of flow rate on conversion

Tubular Reactor : Order Code - 32328

Tesca Tubular Reactor 32328 is in the form of a tube wrapped in a spiral around an acrylic former which is enclosed in a transparent tank. Water at a controlled temperature (from the 32326 Series) is circulated within the tank, this maintains the reactants at constant temperatures.

The reagents are separately piped to the reactor through quick release fittings mounted on the lid and are pre-heated in stainless steel coils in the water tank, before being mixed and fed into the reactor coil. Mounting positions are provided for the water temperature sensor (in the water tank) and the conductivity probe (at the reactor output).

32327 uses the saponification reaction and uses conductivity to measure the progress of the

reaction.

Demonstration Capabilities

Determination of reaction rate constant

Investigation of the effect of throughput on conversion

Demonstration of the temperature dependence of the reaction and the rate constant

Determination of the residence time distribution

Study of the effect of flow-rate on conversion

Transparent Batch Reactor : Order Code - 32329

The Tesca Transparent Batch Reactor 32329 is a double skinned glass vessel with a one litre internal working volume, fitted with a variable speed agitator. Hot water or cold water from Reactor can be circulated through the jacket for temperature control purposes, maintaining the reactor contents at constant temperature. Glands in the clear acrylic lid allow the conductivity and temperature probes to be fitted to facilitate monitoring of the reactions in progress such as the important saponification reaction. Isothermal and adiabatic operation reactions may be demonstrated.

(Note, the Isothermal reaction requires the Tesca accessory if experiments at low temperature are to be studied or if the ambient temperature is high). For adiabatic operation, the use of dyes allows the chemical reaction rates to be monitored visually by the change in colour at different degrees of conversion.

Demonstration Capabilities

Determination of the reaction rate constant

Investigation of the effect of reactant concentration on the reaction rate

Investigation of the effect of temperature on conversion

Visual monitoring of the chemical reactions

Study of the temperature variation of an exothermic reaction on an adiabatic operation.

Note: Model is designed for use with the service unit. Model can be used with the service unit but a nadditional temperature sensor will be required for complete functionality.

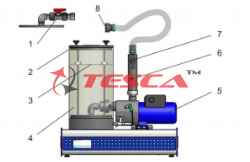

Plug Flow Reactor : Order Code - 32330

The Tesca Plug Flow Reactor 32330 demonstrates step and pulse changes for Plug flow characterization and steady state conversion for a second order reaction. It is a tubular packed column reactor made of clear acrylic and mounted on a steel frame. A static pre- mixer at the bottom of the column provides pre-mixing of the reagents entering the reactor and improves the flow distribution.

A clear acrylic sensor block is mounted on the floor standing frame and houses the conductivity and temperature sensors. The reagents

are fed to the reactor by the feed pumps, using PTFE tubing. A 6 port injection valve fitted to the Reactor service unit is used to provide the step or pulse input changes of the reagents. Tracer experiments and conversion experiments may be demonstrated and followed visually. Conductivity data logging allows the student to apply the flow pattern characterization theory and compare it with the experimental results.

Demonstration Capabilities

Determination of the residence time distribution of the reactor

Study of the reactor response to different perturbations: step and pulse change

Effect of flow rate and feed concentration on the determination of flow pattern

Demonstration of the flow pattern in the reactor and comparison with the theoretical model

Determination of the steady state conversion of a second order reaction Ÿ Effect of flow rate and feed concentration on the steady state conversion Ÿ Visual demonstration of the reactor response with tracer techniques

Visual monitoring of the steady state conversion for a chemical reaction

Laminar Flow Reactor : Order Code - 32331

The Tesca Laminar Flow Reactor 32331 is a tubular reactor made of clear acrylic and mounted on a floor standing steel frame, with two diffusers packed with glass beads located at the ends.

A static pre-mixer at the bottom of the column provides pre-mixing of the reagents entering the reactor and improves the flow distribution. It includes two reagent vessels fitted with heat exchangers, mounted in the plinth. The heat exchangers are used to cool down the reagents before performing the experiment. A cold water jacket keeps the reactor contents at constant temperature in order to maintain the laminar characteristic. A thermostatically controlled supply of chilled water. A clear acrylic sensor block is mounted on the frame for the conductivity and temperature sensors. The reagents are fed to the reactor by the peristaltic pumps, using PTFE tubing. Pulsation dampers are used to ensure a smooth flow. Tracer experiments and conversion experiments may be demonstrated and followed visually. Conductivity data logging allows the student to apply the flow pattern characterization theory and compare it with the experimental results.

Demonstration Capabilities

Determination of the residence time distribution of the reactor

Study of the reactor response to inlet perturbations step change

Effect of flow rate and feed concentration on the determination of flow pattern

Effect of the temperature on the laminar flow characterization

Demonstration of the flow pattern in the reactor and comparison with the theoretical model

Determination of the steady state conversion of a second order reaction

Effect of flow rate and feed concentration on the steady state conversion

Visual demonstration of the reactor response with tracer techniques and laminar flow

Visual monitoring of the steady state

91-9829132777

91-9829132777