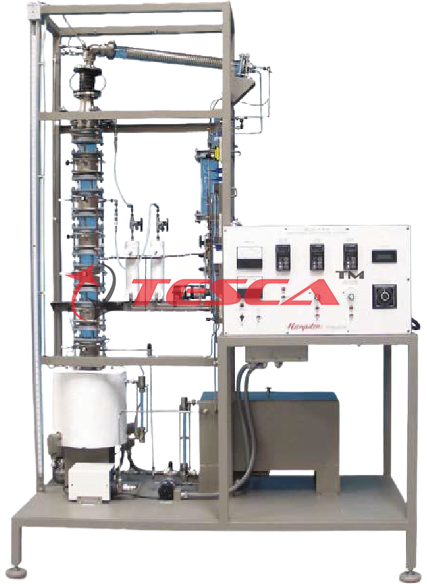

Distillation Column

Order Code: 32363

Category: Thermodynamics Lab

Features Small Scale pilot plant for demonstration of Distillation Process. Wide range of experiments can be conducted on single unit. Comprehensive Instrumentation Panel with all necessa...

SPECIFICATION

Features

Small Scale pilot plant for demonstration of Distillation Process.

Wide range of experiments can be conducted on single unit.

Comprehensive Instrumentation Panel with all necessary safety instruments.

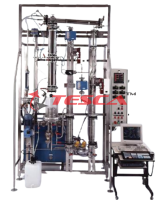

Tesca Continuous Distillation Column has been developed to permit student study of the fundamentals of a continuous distillation system encountered in modern industrial processes. The solution to be distilled is stored in the feed tank. The solution is pumped from the feed tank via the feed metering pump. The distillation column consists of a reboiler, glass column sections, column packing, four packing support plate assemblies, reflux separator assembly, condenser and cap assembly. The distillate feed consists of a reflux three way control valve, distillate spiral cooler, and distillate storage tank. The residue feed comes from the reboiler through the residue spiral cooler to the residue storage tank. Either the distillate of the residue may be pumped back into the feed tank for reprocess. Sampling ports are provided on all packing support plates, feed input, feed output, reflux, distillate tank, residue tank, and reboiler. Thermocouples are used to take all temperature readings

Data Acquisition Software provides real time data on computer screen along with graphs & tabular results. Detailed Operation & Maintenance Manual is provided along with the trainer.

Specifications

A 50mm diameter plate distillation column containing 8 sieve plates and downcomers. Every plate includes a temperature sensor positioned to measure accurately the temperature of the liquid on each plate.

A 50mm packed column for comparative studies of the two types of distillation column.

Electrically heated reboiler of sufficient capacity for 1-2 hours of batch operation.

An overhead condenser with cooling water flow measurement and adjustment.

A condensate collecting vessel

Reflux return valve, solenoid operated.

Differential manometer connected to the top and bottom of the column, to monitor column pressure drop.

Vacuum system with gauge to allow distillation studies at reduced pressures.

Two 5 litre feed vessels,

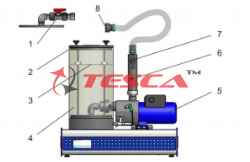

Peristaltic feed pump

Electrically heated reboiler

A bottoms product heat exchanger Temperature sensors in each flow stream entering and leaving the condenser and of the feed, product system and reboiler temperatures.

Experiment Capabilities

Pressure drop across the column as a function of boil-up rate.

Column efficiency as a function of boil-up rate, at total reflux

Binary mixture separation of components with changes in the feed flow rate, feed temperature, reflux ratios and reboiler temperatures.

Comparing Raoult-Dalton Law using the method of McCabe-Thiele

Taking samples and performing appropriate analytical procedures.

Distillation at constant reflux ratio: variation of top product composition with time

Mass balance across the system

Services Required

Electric Supply 230 V AC, 16 A, Single Phase, Earthed.

Personal Computer with USB port, Windows operating system & all peripherals.

91-9829132777

91-9829132777