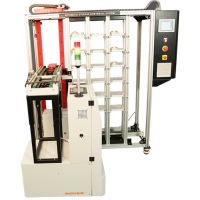

5 Axis Desktop Training Robot

Order Code: 54024

Category: Mechatronics/ Robotics/ CNC Lab

54024 is a user-friendly table-top 5 axis articulated robot. The robot is constructed with die cast aluminium for durability and built with standard stepper motors in the joints. For gripper actuation, the robot uses an RC servo motor. The robot is l...

SPECIFICATION

54024 is a user-friendly table-top 5 axis articulated robot. The robot is constructed with die cast aluminium for durability and built with standard stepper motors in the joints. For gripper actuation, the robot uses an RC servo motor. The robot is light and easy to use. The robot consists of a dedicated motion controller. The controller is an plug-n-play controller with a USB cable for swift interfacing. The robot kit is a self-installation kit. The users can use the M-Robot software to follow the steps of installation, commissioning and operating the robot immediately. Simple online programs can be quickly written and saved. The Application Kit will consist of an aluminium profile plate, a pallet, balls (10 no's), a gravity feeder, building blocks, a paint kit.

Objective

Programming and control of the robot for general purpose application or special purpose application both thru manual as well as Auto mode control for repetitive tasks. Discern & understand the stepper motors, RC servo motor functionality & control methodology.

Learning Objectives:

Having successfully completed this lab, the student will demonstrate knowledge in –

- Study of Classification of robots

- Study of kinematics of robot

- Programming techniques

- Application of robot

- control aspects of various Driving system (Stepper & RC servo)

- Understanding of robot inter-joints, kinematics and control methodology.

- Demonstrate knowledge in the control system of robot

- Demonstrate knowledge in the operating industrial robots.

- Learn about the maintenance of these systems

Training Skills–

- Introduction to Robot programming & Driving system (Stepper & RC servo)

- Theoretical & practical knowledge

- Understand of robot kinematics

- Programming techniques

- Robot programming using Lead through & Teach method.

- Programming logic in Joint/axial and world co-ordinates.

- Trouble shooting & safeguarding

- Learn about the Possibility of Faulty programming and corrective methods.

- Learn about the Systematic approach to troubleshooting of joints/actuators.

Experiments –

- Robot programming for a pick & place using world co-ordinates and teaches method.

- Programming for a stacking operation using axial co-ordinates and Lead Through method.

- Teach a robot for painting application using the joint programming in teach mode.

- Write a program to palletize an array of balls under material handling applications.

- Write down simple Programming with simultaneous movement

- Teach a robot with simple loop Program for loading/unloading.

- Program a robot with loop programming with various speeds

- Program using wait command & gripper

- Study on the merits and demerits using various programming techniques and logic. Justify it with suitable applications.

- Teach a robot for loading/unloading in mini application using the joint or axial programming in lead through method.

- N – no. of numerous experiments and operations possible within the work envelope.

91-9829132777

91-9829132777