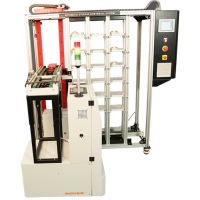

Mechatronics Automation Training Kit for Flexbile Assembly System. Industry 4.0 Compatible

Order Code: 54032

Category: Mechatronics/ Robotics/ CNC Lab

The Flexible Automation System is an exceptional system, where no single unit /module in this system is static i.e. modules in this system can be configured according to different exercises. This system can configured into many number of grouped or s...

SPECIFICATION

The Flexible Automation System is an exceptional system, where no single unit /module in this system is static i.e. modules in this system can be configured according to different exercises. This system can configured into many number of grouped or stand-alone exercises. Base plates are stacked in the linear stacking module and the top plate for assembly is placed in the capping unit while the screws are fed from the screwing module. Set of sensor identifies the presence and type of part, and a linear indexing module indexes to the next station, where it rejects or passes the part to the next module depending upon the type of material.

The part is then indexed to next station where the capping takes place. Then using a rotary transfer arm, it is placed in the Rotary table. The rotary table indexes to the screwing module for joining both the components using a screw. Once screw assembly is done the rotary table indexes to the printing station for printing operation and finally it is placed on the conveyor by the linear pick & place.

This station covers Linear indexing module, Rotary Transfer, Pick & Place, Rotary Table, Stacking module, Capping module and Pusher module. Optionally, it can further be customized by adding filling or drilling & drill depth inspection system. There is a no. of possibilities of usage, the details of which are enclosed.

All the modules are standard & sturdy can be used for different automation application. The system is supplied with complete PLC control module with possibility of using the modules plug & sockets.

Key feature of this system is that

- it is fully reconfigurable by the students and teachers to use the mechatronics components to create new processes.

- It is easy to introduce faults in the system and have the students learn about systematic troubleshooting and problem solving.

- Detailed 250 hours of curriculum is available for teachers to conduct the training, from fundamentals to mechatronics applications.

Essential and common to build a station/system

a) Base plate of size 740mmX640mm

b) FRL and air supply accessories shut-off valve and 5m tube of diameter 8mm

c) Control box with power module, cycle start/ON/OFF switch connection

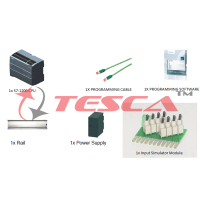

d) PLC trainer based on the Number of modules used:

RECOMMENDED:

PLC: SIEMENS PLC

- Input: 24 V digital input

- Output: Relay outputs

- One base unit;

- Seven expansion units; The PLC has 32 inputs and 24 outputs

- Digital image size 128 inputs, 128 outputs Analogue image size 32 inputs, 32 outputs

Learning Objectives:

Having successfully completed this lab, the student will demonstrate knowledge in – In Automation Technology

- Basic concepts in automation.

- Basic applications of automation in industries

- Advanced applications of Sensors, Pneumatics in automation.

- Demonstrate a familiarity in the working of such systems & Production Planning

- Learn Robotics & Automation technology.

- Study the actual control system used in industries

- In-depth training in fault detection & correction

- Learn about the maintenance & servicing of these systems

TECHNICAL SPECIFICATIONS

- Key Advantages of Tesca Mechatronics systems:

- The industry is looking for students who have skills and knowledge of integrated engineering technologies and problems solving skillsets. Tesca’s Adv Mfg & Automation training solutions are designed to deliver the same through our Industry 4.0 Smart Factory, and Smart Mechatronics products. We have already delivered over 50+ systems globally to highly reputed educational institutions.

- The Tesca product portfolio is ready for Industry 4.0 integration and IIOT Training

- Our training solutions are developed with focus on delivering skills and transferrable knowledge that students can carry from their classroom/ labs to the industry

- Our hardware is accompanied with world-class online training courses (SKILLON365)

- IOT Ready: Equipment is Internet of Things ready and can be interfaced with IoT platform. This is an option.

- Digital Twin: Digital twin is available for all mechatronics system as an option.

- Approach to the design, construction, training and future ready concepts aligned with European and American educational system

- Train on Automation in Circuit: Understand how automation works - from simple to complex circuits

- Train on Automation in Application: Understand how automation works in industries - from simple to complex applications, programming & control

- Train on Automation in Maintenance:Understand how to identify faults and troubleshoot in automation -variety of exercises to train in this area

- SKILLON365: Online courseware that gives the users flexibility of selecting courses from a variety of technologies and changeable each year.

- Tesca modules are built for durability, robustness and performance, high quality and aesthetic finish

- Highly reliable components: Pneumatics from Festo, PLC from Siemens, Sensors for reputed international manufacturers, Mechanical components from reputed international industrial suppliers

- Serviceability: We support our product globally through our reselling partners and through "Going Digital with Tesca" platform, where you can connect with our service specialists through asynchronous communications or synchronous communication means

MODULES:

A module is a stand alone functional unit. It is complete with necessary pneumatic and/or electrical actuator, internal electrical switches and connections, pneumatic connections for operation. The modules are provided with quick connecting miniatures for electrical contact.

1. Aluminium Profile Plate

Aluminium Profile Plate for mounting all pneumatic & other components to the modules. A Mobile trolley which can fit the aluminium profile plate is provided as optional. All electrical and electronic items shall be housed in the bottom of the trolley below the platform

2. Belt Conveyor Module

The conveyor module conveys the part from one end to another. Specification:

- Motor : 12 V DC power motor

- Length : 420mm

- Height : 60mm

- Width : 40mm

- Belt : Nylon fabric belt

- 4 gates provided for fixing sensors and part ejection.

- Knob screw (1 no) and T-nuts of diameter M6 are provided for quick fixing of the module on profile plate.

3. The Linear Pick And Place (LPP) Module

Specification:

- Double acting pneumatic cylinders : 2

- Single acting pneumatic cylinders : 1

- Reed switches : 4

- Solenoid coils : 5

- Horizontal stroke : 80mm

- Vertical stroke : 20mm

- Mounting : Knob screw (1no)

Scope of supply

Quick mounting knob screw and T-nut – 1 Pneumatic module

Air supply module

4. The Rotary Pick And Place (RPP) Module

The rotary pick and place (RPP) module picks the work piece from one position, horizontally r places the work piece to another position.

The part shall be moved to next location for processing, in a rotary manner. The module is a unit with readiness to connect electrically and pneumatically through external valve modu actuate the function. The module is completely ready to mount with quick mounting knob scr slotted n tube.

Specification:

- Double acting pneumatic cylinders : 3

- 5/2 Single acting solenoid valve : 1

- 5/2 Double acting solenoid valve : 2

- Reed switches : 4

- Rotation angle : 90º

- Vertical stroke : 20mm

- Mounting : Knob screw (1no) Scope of supply

- Quick mounting knob screw and T-nut – 1 Pneumatic module

- Air supply module

6. Rotary Indexing Table (rotary Carousal Table)

The rotary indexing module indexes and moves the work piece to the destination position in its platform. Rotary indexing module is to move workpiece location in fixed intervals up to 3 indexing which can be further expanded based on the project. The customer can specifically request for additional indexing. The workpiece shall be indexed to next location for processing, in a rotary manner. The module is a stand alone functi connect electrically to PLC and I/Os to actuate the function.

Specification:

- Mounting : Knob screw (2nos)

- Home sensor : 1

Scope of supply

Quick mounting knob screw and T-nut – 2 Pneumatic module

Air supply module

7. Air Supply Module (FRL Unit)

This consists of the air filter, pressure regulator and lubricator unit, and supplies compressed air to control the movement of the pneumatic cylinders.

Pressure regulator – The pressure regulator maintains a constant output pressure independent of pressure fluctuations and air consumption. The output pressure can be reduced by means of a secondary venting without compressed air consumers.

Air filter – The air filter removes contamination, pipe sinter, rust and condensate from compressed air.

Lubricator – The proportional lubricator adds precision adjustable quantity of oil to the compressed air. The oil droplets are atomized just downstream from proportional valve in the air duct. The oil mist component is proportional to the compressed air flow rate.

Scope of supply

Quick mounting knob screw and T-nut – 1 shut-off valve and 5m tube of diameter 8mm

8. Valve Modules

The valve modules are provided to connect different pneumatic actuators or other pneumatically operated modules.

Scope of supply

- Bracket with quick mounting knob screw and T-nut – 1

- 5/2 double acting solenoid valve

- 5/2 single acting solenoid valve

- port manifold with 4mm

- Male connector (Pu6mm)

- Tube 5m – 1 No

9. Linear Indexing Module

Linear indexing module is to move part location in fixed intervals up to 3 indexing which can be further expanded based on the project. The customer can specifically request for additional indexing. The part shall be linearly indexed to next location for processing. Provisions are provided for mounting sensors and gates are provided for laterally displacing/displaying the part. The module is a stand alone functional unit with readiness to connect electrically and pneumatically through external valve module and PLC and I/Os to actuate the function. The module is completely ready to mount with quick mounting knob screw and T-nut on 8mm T-slotted tube. The linear indexing module indexes the part from one port to another.

Total length – 350 mm No of indexing – 3

Specification:

Double acting pneumatic cylinders : 2

5/2 Single acting solenoid valve : 1

Reed switches : 4

Mounting : Knob screw (1no)

Scope of supply

Bracket with quick mounting knob screw and T-nut – 1 Pneumatic module

Air supply module

10. The Dispensing Module

The dispensing module dispenses the work piece from the magazine to specific position in transfer module.

The part shall be moved to desired location for processing, from the dispensing magazine. The module is a stand alone functional unit with readiness to connect electrically and pneumatically through external valve module and PLC and I/Os to actuate the function. The module is completely ready to mount with quick mounting knob screw and T- nut on 8mm T-slotted tube.

Specification:

- Double acting pneumatic cylinders : 1

- 5/2 Single acting solenoid valve : 1

- Reed switches : 2

- Horizontal stroke : 40mm

- Mounting : Knob screw (1no)

Scope of supply

Quick mounting knob screw and T-nut – 1 Pneumatic module

Air supply module

11. The Pusher Module

The pusher module pushes the work piece from one position to another position.

The part shall be pushed to desired location for processing. The module is a stand alone functional unit with readiness to connect electrically and pneumatically through external valve module and PLC and I/Os to actuate the function. The module is completely ready to mount with quick mounting knob screw and T-nut on 8mm T-slotted tube

Specification:

- Double acting pneumatic cylinders : 1

- 5/2 Single acting solenoid valve : 1

- Reed switches : 2

- Horizontal stroke : 80mm

- Mounting : Knob screw (1no)

Scope of supply

Quick mounting knob screw and T-nut – 1 Pneumatic module

Air supply module

12. The Slide Bed Module

The slide bed module accommodates the work piece from the transfer or working modules. Specification:

Mounting : Knob screw (1no)

Scope of supply

Quick mounting knob screw and T-nut – 1

13. The Assembly Module

The assembly module assembles the circular work piece from the magazine, into the pocket in the rectangular work piece. The circular part shall be assembled into the pocket in the rectangular work piece. The module is a stand alone functional unit with readiness to connect electrically and pneumatically through external valve module and PLC and I/Os to actuate the function. The module is completely ready to mount with quick mounting knob screw and T-nut on 8mm T-slotted tube.

Specification:

- Double acting pneumatic cylinders : 2

- 5/2 Double acting solenoid valve : 2

- Reed switches : 4

- Vertical stroke : 40mm

- Horizontal stroke : 40mm

- Mounting : Knob screw (1no)

Scope of supply

Quick mounting knob screw and T-nut – 1 Pneumatic module

Air supply module

14. The Screw-fixing Module

The screw-fixing module screws and fixes the circular work piece to the rectangular work piece. The circular part shall be screw-fixed into the pocket in the rectangular work piece. The module is a stand alone functional unit with readiness to connect electrically and pneumatically through external valve module and PLC and I/Os to actuate the function. The module is completely ready to mount with quick mounting knob screw and T-nut on 8mm T-slotted tube.

Specification:

- Double acting pneumatic cylinders : 1

- 5/2 Single acting solenoid valve : 1

- Reed switches : 2

- Vertical stroke : 40mm

- Mounting : Knob screw (1no)

Scope of supply

Quick mounting knob screw and T-nut – 1 Pneumatic module

Air supply module

14. The Printing Module

The printing module prints patterns on to the work piece. The part shall be printed . The module is a stand alone functional unit with readiness to connect electrically and pneumatically through external valve module and PLC and I/Os to actuate the function. The module is completely ready to mount with quick mounting knob screw and T-nut on 8mm T-slotted tube.

15. Work Station Details

- Each station is mounted an aluminum profile plated that is placed on a mobile trolley and fitted with PLC as required by the station. Aluminum Profile Plate for mounting all pneumatic & other components to the modules. All electrical and electronic items shall be housed in the cabinet of the trolley below the platform. Operating console with Push button for start, stop, two way selector switch, power switch, emergency stop button - 1No.

- Power Supply Unit with - 1No. Input Voltage: 220/110V & 12A, 50/60 Hz, Single Phase Output Voltage: 24V DC Output Current: 4.5A with short circuit protection 24 V Compact Relay Fully wired & Programmed PLC Unit is provided with

- a) Siemens PLC S7-1200 CPU - 1No. Digital Inputs: 24 Digital input,16 Digital output & 2 Analog input Process image: 1024 bytes for inputs, 1024 bytes for outputs Work memory (integrated)-100 KB, Load memory (integrated)-4 MB

- b) Communication cable - 5Nos.

- c) PLC Programming Software - TIA Portal Basic Step 7 (v13 sp1):Programming Language: Comply IEEE programming language capability. - 5Nos.

- Service Unit: FRL Unit with pressure regulator, pressure gauge with maximum pressure 10 bar. Shut off value will be provided with FRL. Switch Knob will be provided in all stations. - 1No.

- Work pieces

- Metal and Non Metal Square Billets - 7Nos.

- Round Billets - 7Nos.

- Electrical Cabinet: - 1No.

- Accessible electrical connection terminal box with power input and coded I/O.

- Industrial communication with others station via standard communication protocol.

- Communication interface: Ethernet port.

- Include hard wired and PLC program (manual and auto mode operation)

- Communication interface: Ethernet port.

- All wiring cables are properly identified and labelled at both ends.

- All pneumatic cables and tubing are properly identified and labelled at both ends.

- Dimensions - 1500x900x1400mm

- Weight - 140kg

Basic Exercises:

- To move the Horizontal conveyor when the start is pressed and moves it back to home position after 10 sec.

- To push-out the material from the linear stacking module when the start button is being pressed.

- To make the Linear indexing module to index the part to the pusher module once the start button is pressed.

- Program to Start and stop the conveyor/Linear module using single button at any locations.

- To actuate the conveyor/Linear module only when both button pressed simultaneously (Green & Red).

- To detect the type of component and push the rejected material out using the pusher module.

- Actuate the Linear stacking module for the first press and then actuate Linear indexing module for the next press of the button (acting as manual Trigger)

- Transfer the job from Rotary table to conveyor using the Pick & place unit.

- To run the linear conveyor/Rotary module continuously when the start switch is pressed.

- To run the conveyor when start button is pressed and automatically stop it after a time delay 10 sec.

Advanced Exercises:

- Programming of stacking module to index the part out to the linear indexing module and check for the type of parts.

- Programming of Rotary Indexing Module with memory array for the station address.

- Programming and control of screwing module and integrating with the printing module to form a closed loop system.

- Programming & control of Linear Indexing Module.

- Program to manual triggered rotary indexing module to rotate by a slot and carry out the Screwing operation and move it to next position.

- Program for Auto conveyor transit / return for material transfer with timer and Feedback control.

- Program to manual triggered rotary indexing module to rotate by two slots and carry out the Printing operation followed by placing the part in the conveyor module using the Linear pick & place.

- Program the pusher module to by-pass metal / Non-metal components and then carry out the capping operation and place the part for the next station using the rotary pick & place.

- Program to sensor trigger/manual triggered and to make the Linear indexing module to index by two positions capping module to carry out the capping process and returning back to the initial position.

- Try out the reverse way feeding the part from conveyor, index using the rotary module for printing and place the part in the Linear indexing module using the Rotary pick & place.

- Any numbers of combination modules are possible by configuring it differently according to the applications of the user.

REQUIRED EQUIPMENT AT SITE AND UTILITIES TO BE PROVIDED BY THE BUYER DURING COMMISSIONING, DEMONSTRATION & TRAINING

For 54032

- Compressor - 100 Litre tank Capacity, 6 to 8 Bar (100 – psi) - 1No

- Desktop computer required with specification below

- Operating System : Windows 7 Professional or higher

- Processor Required At least 2.4 GHz or equivalent, RAM : at least 4 GB

- 19 inch LCD Monitor - 1 no

SET OF STANDARD OPERATION AND MAINTENANCE SPARES FOR ONE YEAR

Photoelectric sensor : 1Nos.

Capacitive sensor : 1Nos.

Reed sensor : 2No.

fuse : 10Nos.

base billets : 7Nos.

base billets ( Non metal) : 3Nos.

Round billets : 7Nos.

screw M6x10 : 12Nos.

PU 8 Hose : 5Nos.

PU 4 Hose : 5set

PU 6 Hose : 5set

M6 profile slot stone tennon : 20Nos.

Allen key : 1set

screw driver set : 1set

cleaning brush : 1No.

double ended spanner - 8X9,10X11,20x22 : 1set

M6 mounting knob : 10Nos.

teflon tap : 1No.

Set of Spares

Photoelectric sensor : 1 Nos.

Capacitive sensor : 1 Nos.

Fuse : 10 Nos.

Relay : 2 Nos.

Workpieces : 4 Nos.

Pneumatic hose : 2 mtr

91-9829132777

91-9829132777