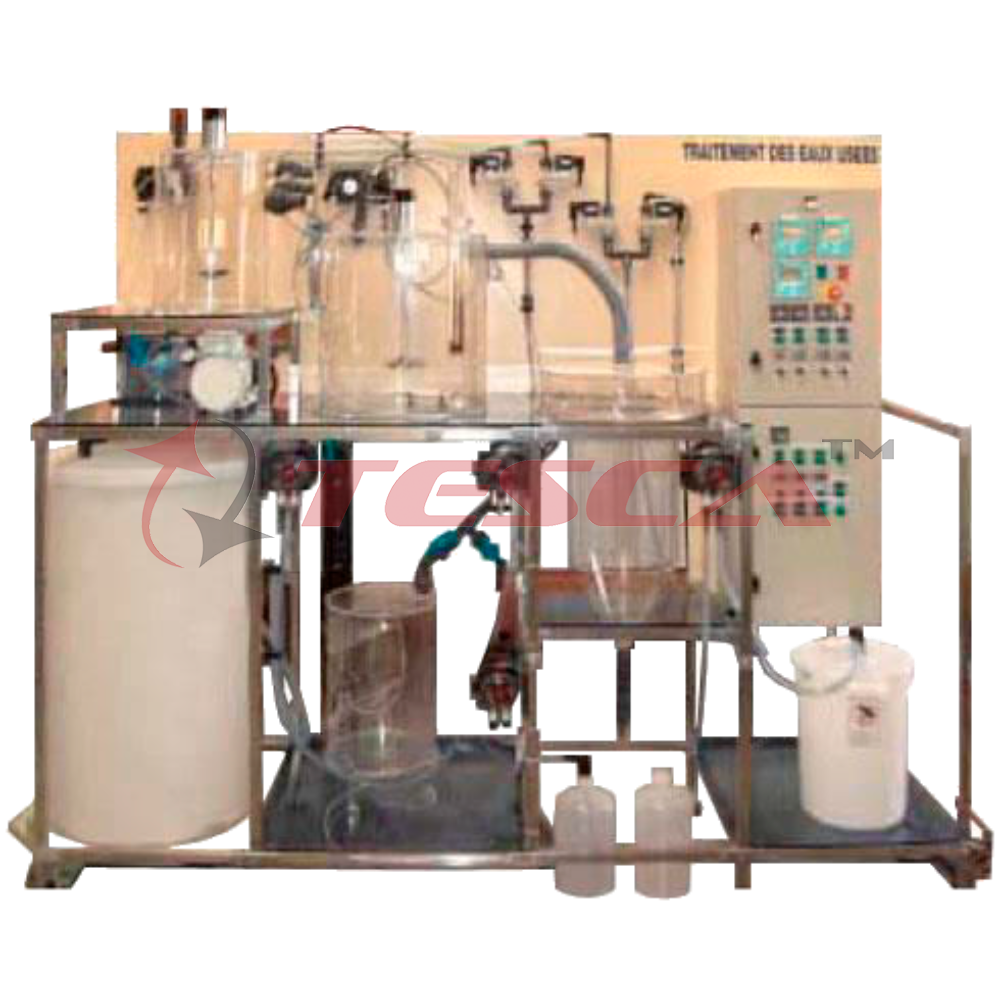

Automated Sludge Sewage Treatment Plant

Order Code: 32472

Category: Environmental Trainers

Tesca Automated Sludge Sewage Treatment Plant 32472 activated sludge sewage treatment pilot plant is a small scale industrial sewage plant. It consists of all the comprehensive components and advance process control instrument to make the trainer mor

SPECIFICATION

Principal Teaching Objectives

Tesca Automated Sludge Sewage Treatment Plant 32472 activated sludge sewage treatment pilot plant is a small scale industrial sewage plant. It consists of all the comprehensive components and advance process control instrument to make the trainer more interesting on study.

All the tank, components, instrumentation are mounted on mobile workbench with caster roller. The bench is made of stainless steel frame. Table top is made of durable ABS plastic material which can withstand the wet and chemical resistance.

The main control instrumentations consists of PLC, analog data acquisition card, input and output digital module pH control, O2 controller, Redo X controller, temperature controller comprehensive aluminum etching mimic diagram with indicating light and alarm annunciator. All analysis controller is link to PC with data acquisition software. The setup of instrumentation communication are using modbus RTU RS485 which is widely used in modern sewage treatment plant. The operation status of the pump, solenoid control valve are able to controlled by PC Experiment Possibilities

1. Study & measure of BOD (Biological Oxygen Demand) unit & COD (Chemical Oxygen Demand)

2. Process of substrate flow

3. Effect of the temperature on the purification

4. Influence of PH and Oxygen on treatment process

5. Air injection time

6. The influence of dissolved oxygen concentration

7. Sludge recirculation flow process

8. The effect of stirrer speed on treatment process

9. Determination of the purification effect of stay time in oxidation tank

10. Determine the purification effect on mixing

11. Effect of different concentration of dissolved O2 on treatment plant’s efficiency

12. Determination of sludge sedimentation varying the concentration of work O2

13. Influence of the activated carbon on the purification process

14. Testing using O2 instead of air (10 liter oxygen fill cylinder is provided)

The control function of pilot plant consists of two modes:

Fully automatic mode

This model is fully automotive control by PLC, which analysis data feed back by the controller

Manual mode

- This mode, student can commend any control sequence via the PC control software, this is to facilitate the simulation and generate various type treatment process phenomenon and faults. This to enhance the student understanding and chemicalphysical problem arising from the realization of an activated sludge process.

- The value of the analysis carried out in laboratory (COD, BOD, MVS etc…) could be set by the operator to be taken into account in the formulas of flow instruction.

The process flow-line

- Aerobic condition of cultivates the Micro-organism

- Micro-organism digest the contaminated substances

- After the pollutant elimination phase, it is further divide into clarified water and go to settling tank

- The clarified water is further sterilized, while the activated sludge is partially recycled within oxidation tank in order to stabilize the treatment process.

Practice provide and other training provided:

- The agitation effect on the treatment tank

- Advantage of air-lift in the sludge recirculating system

- Effect of oxygen concentration on the sludge elimination

- Technical Specifications

Air line system

- Pressure regulator, range : 0 to 9 bars -1

- Two gas rotameter

- Flow controller ½” BSP - 2

- Flow control solenoid valve ½” BSP, 24Vdc - 1

- Air distribution/diffuser for reactor - 1

- “Air lift” system for sludge recirculating tank - 1

- Air pump 700 I/h, 2 bar - 1

Liquid line

- Feed preparation tank with stirrer, 30 liter glass tank with stirrer and variable speed controller - 1

- Volumetric feed pump to study dilution control peristaltic pump, 230V, 50Hz, 350mA, Flowrate 1.5, 5 and 10 liter per hour adjustable by changing the tube size - 1

- Plexiglas/Glass reactor tank, 25 liters - 1

- Plexiglas/Glass settling tank with air lift, 30 liters - 1

- Air injection rod - 1

- One turbine flowmeter - 1

- Two peristaltic pump to recycle the sludge card supply the substrate - 1

- Collection tank for purified water - 1

- emperature probe for measuring oxidation tank’s temperature PT100 probe - 1

- Continuous pH measuring probe with transmitter and digital PID controller c/w galvanic separator - 1

- Continuous dissolved oxygen measuring probe with transmitter and digital PID controller - 1

- Two injection pump for acid and base regulated at pH measurement - 1

Additional instruments optionally provided:

- A cone to determine the percentage of sludge preset

- A set of chemicals to create a favorable environment for bacterial cultures

- A quantity of lyophilized bacteria

- Migrates percentage detection paper

- pH detection paper

- Pump feeding, rate of stirrer are control by PLC with digital to analog conversion module and PID control function. Sampling rate 12 bit / 10 KHZ

- PC link to pilot plant PLC module

- DAQ data acquisition software, window XP OS

91-9829132777

91-9829132777