Batch Enzyme Reactor

Order Code: 32340

Category: Thermodynamics Lab

Features A batch enzyme reaction system utilizing the industrially important glucose isomerization reaction (converting glucose to fructose) catalyzed by glucose isomerize. The purpose of the unit is to demonstrate batch enzyme kinetics and enzyme c...

SPECIFICATION

Features

A batch enzyme reaction system utilizing the industrially important glucose isomerization reaction (converting glucose to fructose) catalyzed by glucose isomerize. The purpose of the unit is to demonstrate batch enzyme kinetics and enzyme characteristics. The reaction takes place inside a stirred vessel where the stirrer itself is a porous basket inside which the enzyme is immobilized. A Polari meter device which is integral to the unit monitors the glucose and fructose concentrations with time.

Tesca Batch Enzyme Reactor introduces the student to the fundamentals of batch enzyme catalysis. It consists of a bench-top unit onto which is mounted a reactor vessel in which the glucose isomerize- mediated reaction takes place. The reactor itself is made of clear acrylic which gives good visibility. A cruciform geometry impeller constructed from stainless steel mesh retains the immobilized enzyme whilst allowing efficient mixing with the liquid reactant (glucose solution). The impeller is a variable speed type. The reaction temperature is maintained using two heaters and a temperature sensor mounted within the reactor. These are linked to a PID controller which is programmed to maintain the desired set- point temperature. Safety interlocks prevent the heaters being activated when there is a low reactor liquid level or when the impeller is inactive.

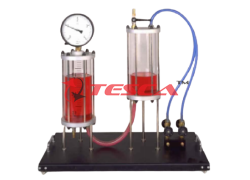

A continuous sampling loop driven by a peristaltic pump removes liquid from the reactor and transfers it to a tubular coil heat exchanger where it is cooled prior to passing through a polarimeter where the angle of rotation of polarized light is measured. From this angle measurement the concentration of both glucose reactant and fructose product can be determined. This eliminates the need for manual glucose assays. The measurement system relies on the fact that both glucose and fructose solutions rotate beams of polarized light, glucose to the right and fructose to the left. The polarimetry measurement method allows the progress of the reaction to be monitored on-line. The polarimeter assembly (Fig 1) consists of an elongated optical flow cell mounted between two polarizing lenses, one of which is fixed (polarizer) and the other being free to rotate (analyzer). On the outside of the polarizer is a light source and on the outside of the analyzer is a detector which detects the intensity of emitted light that has passed through both polarizing lenses and the sample tube.

Attached to the analyzer is an angle measurement device. Both the optical transmission and the angle of rotation are relayed to electronic displays on the control console.

Experimental Capabilities

Understanding the principles of batch enzyme kinetics

Understanding the factors affecting enzyme performance

Understanding the principles of polarimetry and Biot’s law.

Teaching exercises are included to familiarize the students with the following topics:

Determination of Michaelis-Menten constants and specific enzyme activity through Michaelis Menten and Lineweaver-Burke plots

Determination of glucose and fructose concentrations through polarimetry

Effect of environmental conditions (pH and temperature) on enzyme activity

Demonstration of Biot’s law

Electronic outputs from the sensors are available for data logging and analysis. The data logger interfaces between the BE1 and the user’s computer via a USB port. The associated software provides a mimic diagram (Fig 2) with current sensor values displayed. Also incorporated in the software are graph plotting facilities, full instructions on equipment set-up and experimental methods, related theory and full help texts. The software requires a computer running Windows 98 or Windows 2000 with a USB port.

Specifications:

1. A bench top unit comprising a vacuum formed ABS plastic plinth with integral electrical console onto which is mounted the stirred reactor vessel sampling circuit with peristaltic pump, tubular coil heat exchanger and polarimeter device.

2. A temperature sensor and heater mounted in the reactor vessel and linked to a PID controller for accurate reaction temperature control.

3. A polarimeter device measuring optical transmission and angle of rotation.

4. Protection devices for all electrical circuits.

5. Three displays: PID temperature control (reactor temperature), display for angle of rotation, display for optical transmission or temperature at polarimeter.

6. Sensor signals are routed to the I/O port for connection to a PC

7. Comprehensive instruction manual with detailed laboratory teaching exercises

8. Instructional capabilities:

- Principles of batch enzyme kinetics

Factors affecting enzyme performance

Principles of polarimity and Biot’s law

91-9829132777

91-9829132777