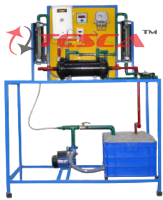

Crystallization Unit

Order Code: 32301

Category: Thermodynamics Lab

Features Designed to demonstrate process of crystallization of salts. Comprehensive Instrumentation Panel with all necessary measuring instruments & Safety Devices. Tesca Cooling Crystallization Unit is designed to demons...

SPECIFICATION

Features

Designed to demonstrate process of crystallization of salts.

Comprehensive Instrumentation Panel with all necessary measuring instruments & Safety Devices.

Tesca Cooling Crystallization Unit is designed to demonstrate process of crystallization of dissolved substances from solutions to be transformed into a solid and separated. A pump delivers a saturated potassium sulphate solution in a circuit with a tank. To prevent premature Crystallization, the solution is heated above saturation temperature using a heating circuit. Both circuits are connected by two heat exchangers. A small amount of this under saturated solution is fed through the crystallization cell as a bypass. To crystallize this part of solution, it is cooled by cooling water using two heat exchangers. Reducing the temperature converts the solution into an oversaturated, metastable state

Detailed Operation & Maintenance Manual is provided along with the trainer.

Specifications

Tanks

Stirred tank : approx. 25L

For under-saturated solution: @ 25L

Heating circuit: @ 32L

Pump (solution)

Max. flow rate: @ 21lmin

Max. head : @ 38m

Pump (heating circuit)

Max. flow rate : @ 6L/min

Max. head: @. 9m

Crystallization cell

Diameter : @ 40mm

Height: @ 80mm

Heater power output: @ 2kW

Measuring ranges

- Temperature : 3 x 0 … 100?C. 1x 0.. 80?C

Flow rate 1 x 0 .. 12L/min

Experiment Capabilities

Fundamental principle of cooling crystallization

Investigation of the factors influencing crystallization process

Concentration of the solution

Temperature

Time

Services Required:

Electric Supply 230 V AC, Single Phase, Earthed.

Cooling Water: Cold water supply & Drain.

91-9829132777

91-9829132777