Thermal Conductivity of Lagged Pipes

Order Code: 32366

Category: Thermodynamics Lab

Features: Visual demonstrations of convective, nucleate and film boiling. Includes series of safety devices for operator safety. Optional Data Acquisition System with sensors & software. Tesca Pool Boiling ...

SPECIFICATION

Features:

Visual demonstrations of convective, nucleate and film boiling.

Includes series of safety devices for operator safety.

Optional Data Acquisition System with sensors & software.

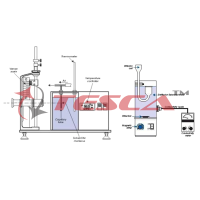

Tesca Pool Boiling Heat Transfer Apparatus has been designed for students demonstrations on convective, nucleate and film boiling. The unit mainly consists of a thick walled glass cylinder fitted internally with a heating element and a coil type condenser. Instrumentations are provided for the measurement of temperature, pressure, flowrate and power. The unit helps students to understand better the heat transfer processes from a hot region to a colder one in countless industrial applications, e.g. thermal and nuclear power generation in steam plants, refrigeration, heat transmission, etc. locally warmed liquid expands and convection currents carry it to the liquid-vapour interface where evaporation takes place and thermal equilibrium is restored. Thus, in this mode, evaporation takes place at small temperature differences and with no bubble formation.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Study of the concept of double & single lagging.

Study of effects of different insulating material combinations.

Electrical input control & measurement with complete panelised instruments.

Digital Temperature Indicator.

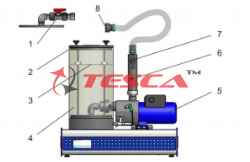

Lagging of pipes is required to prevent leakages of heat. Tesca Thermal conductivity Through Lagged Pipes Apparatus is designed to study the lagging phenomenon. In the Lagged pipe Apparatus, three concentric pipes are arranged between two supports. The gap between the pipes are filled compactly by two different insulating materials and heater is provided at the centre of inner pipe. Temperature at various points is measured with Temperature Indicator. Heat input is measured by Voltmeter - Ammeter. The assembly is mounted on angle frame.

Specifications:

Pipes:

I) M.S. Pipe Inside - 5 cm dia approx.

ii) M.S. Pipe Middle -10 cm dia approx.

iii) M.S. Pipe Outer -15 cm dia approx. Length of Pipe @ 1mtr

Control panel consisting of:

a) Voltmeter -0 - 100/200 volts.

b) Ammeter - 0 -2 Amp.

c) Dimmerstat for heater, 0-230 V, 2 Amps.

d) Digital Temperature Indicator: 0-300 degrees Celcius with 1 degree least count

e) Nichrome Cartridge heater of suitable capacity & length

Experimentation

To determine heat flow rate through lagged pipe and compare it with the heater input for known values of thermal conductivity of lagging material.

To determine thermal conductivity of lagging material by assuming input to be heat flow rate through lagged pipe.

To plot temperature distribution across lagging material.

Services Required

230 V A.C. stabilised supply with earth connection. Ÿ Space area of 2.5 m x 2.5 m at working height. A technical manual describing the equipment and experimental procedure will be supplied alongwith the apparatus

91-9829132777

91-9829132777