Chemical Reactor Trainer

Order Code: 32265

Category: Thermodynamics Lab

Features Basic unit to study and compare various reactors using the example of a saponification High precision, combined conductivity and reaction temperature measurement Usage of industrial diaphragm pumps Optionally...

SPECIFICATION

Features

- Basic unit to study and compare various reactors using the example of a saponification

- High precision, combined conductivity and reaction temperature measurement

- Usage of industrial diaphragm pumps

- Optionally PC interface for data acquisition & control

- Basic unit to study and compare various reactors using the example of a saponification

- High precision, combined conductivity and reaction temperature measurement

- Usage of industrial diaphragm pumps

- Optionally PC interface for data acquisition & control

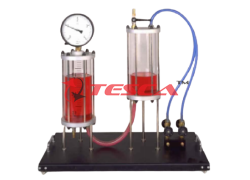

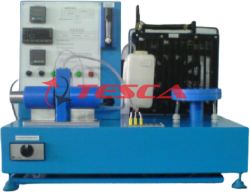

The properties of different chemical reactors can be investigated by performing a saponification reaction using Tesca Chemicals Reactor Trainer. The contact time and reaction temperature can be varied. Their influence on the conversion of reactants is observed in the respective reactor. The reactors are available as accessories. The unit contains two supply tanks for the liquid chemicals. Two variable speed diaphragm pumps pump the reactants through the reactor. Reactant conversion and reaction temperature are measured with a combined conductivity and temperature measuring unit. It is also possible to use optionally PC interface for data acquisition & control.

The reaction is moderated using a controlled hot water circuit. The resulting reaction product is collected in a stainless steel tray in the unit.

Experiments

In conjunction with the various types of reactors available as accessories in the 32265, comprehensive experiments on the reaction kinetics and on the conversion of reactants during a saponification reaction can be performed. Specifically, the following experiments can be performed:

- Variation of contact time of the two chemicals

- Variation of reaction temperature

- Adiabatic reaction in a batch reactor

- Isothermal reaction in a batch reactor

Specifications

Benchtop unit to study the kinetics of reaction kinetics of various types of chemical reactors based on saponification

Chemicals pumped using 2 industrial diaphragm pumps

Reaction of 2.3% sodium hydroxide with ethyl acetate

High precision combined measuring unit for conductivity 0...200mS and reaction temperature 0...100°C

Hot water circuit with centrifugal pump for moderating the reaction

Electrical heater, 2kW

Electronic two-point controller

Self-sealing quick action hose couplings

Technical Details

Diaphragm pump, adjustment range: 0...100%, pump flow rate max. 600ml/min Conductivity measuring range: 0...200mS

Temperature measuring range: 0...100°C

Heater: 2kW, electron. two-point controller

Centrifugal pump

Chemicals used:

Ethyl acetate 5%, sodium hydroxide 2.3%

Dimensions & Weight

1300(L) x 680(W) x 630(H) mm

Weight : approx. 90 kg

91-9829132777

91-9829132777