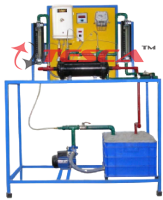

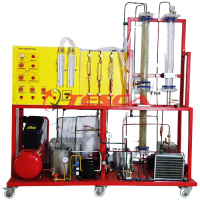

Computer Controlled Heat Exchange Module

Order Code: 32290

Category: Thermodynamics Lab

Features Compact, mobile unit, designed to provide required services for testing various Heat Exchangers using single source. Entire process is computer controlled, including change of direction of flow for parallel & counter- flow analys...

SPECIFICATION

Features

- Compact, mobile unit, designed to provide required services for testing various Heat Exchangers using single source.

- Entire process is computer controlled, including change of direction of flow for parallel & counter- flow analysis.

- Comprehensive Instrumentation Panel with all necessary safety instruments.

Tesca Computer Controlled Heat Exchanger Service Module is designed to provide required services for testing different types of Heat Exchangers. The heat exchangers can be easily fitted on to the service module & wide range of options of heat exchangers are available. The Service module includes Hot water tank with electric heaters & hot water pump. The temperature of hot water is controlled by digital temperature controller. The heat exchanger can be tested in Parallel & Counter flow arrangements as desired & the mode is selected through the software.

The service module also includes required measuring instruments & Data Acquisition Device which can interface with computer through USB Port. Sensors are provided for measuring water temperature at different points, cold water & hot water flow rate.

The entire setup is mounted on sturdy steel frame made of Mild Steel Tubes & Sheets. The entire frame

& panel are powder painted for durability.

Data Acquisition Software provides real time data on computer screen along with graphs & tabular results. Detailed Operation & Maintenance Manual is provided along with the trainer.

Technical Specifications

- Hot water tank made from non-corrosive material.

- Electric Heater: 2kW with Temperature controller

- Water Level Safety Switch

- Hot water pump

- Flow Transmitter – 2 Nos.

- Temperature Sensors – 5 Nos.

- Data Acquisition Device

- DAQ software

Experiment Capabilities

- Demonstration of indirect heating/ cooling by transfer of heat from one fluid stream to another when separated by a solid wall.

- Energy balance determination (heat balance) and calculation of efficiencies by measuring the flow rates and temperature changes in the hot and cold fluid streams.

- Introduction to different styles of heat exchanger and comparison of the differences in operation and performance.

- Using the Logarithmic Mean Temperature Difference (LMTD) in heat transfer calculations.

- Definition and measurement of Overall Heat Transfer Coefficient (U).

- Demonstration of the differences between counter-current and co-current operation.

- Demonstration of the transition from linear to turbulent flow.

- Effect of hot and cold fluid flow rate on the heat transfer coefficient.

- Effect of driving force (temperature differential) on the heat transfer coefficient.

- Investigation of heat loss and reduction in heat transfer coefficient due to fouling of the heat transfer surfaces (suitable student project using user induced. fouling).

Optional Heat Exchanger Modules

Following Heat Exchanger Modules can be readily tested on the service unit:

- Tubular Heat Exchanger & Extended Tubular Heart Exchanger

- Plate Heat Exchanger

- Shell and Tube Heat Exchanger

- Jacketed Vessel with Coil & Stirrer

Services Required

- Electric Supply 230 V AC, 16 A, Single Phase, Earthed.

- Cold Water Supply & Drainage.

- Personal Computer with USB port, Windows operating system & all peripherals.

91-9829132777

91-9829132777