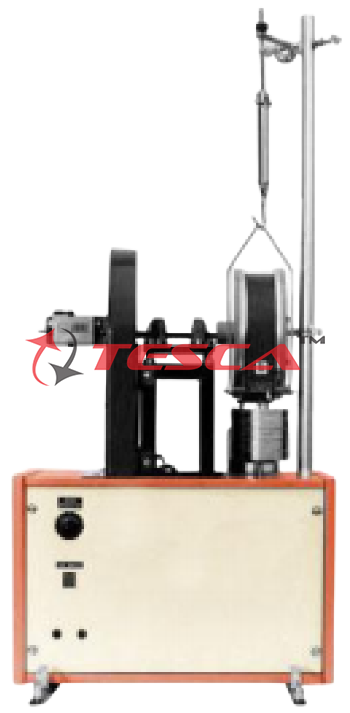

Mechanical Equivalent Of Heat Apparatus

Order Code: 32266

Category: Thermodynamics Lab

Features Mechanical work and heat are different forms of energy. Thermodynamics deals with the transfer of energy in the forms of mechanical work and heat. The equivalence of mechanical work and heat is very well established. The convers...

SPECIFICATION

Features

Mechanical work and heat are different forms of energy. Thermodynamics deals with the transfer of energy in the forms of mechanical work and heat. The equivalence of mechanical work and heat is very well established. The conversion factor between the mechanical energy due to some work and its heat equivalent is referred to as the Mechanical equivalent of Heat. In SI system of units, both mechanical work and heat are measured in Joules and the mechanical equivalent of heat has a value of unity. Experimental determination of the mechanical equivalent of heat is of significant interest to the students of Physics and Thermodynamics.

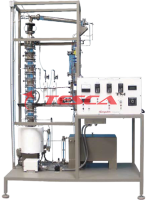

Tesca Mechanical Equivalent of Heat Apparatus has been designed to enable students to study and measure the mechanical work dissipated and the heat energy generated to determine experimentally the mechanical equivalent of heat. Comparisons can be made with the established value of this constant and errors can be analyzed.

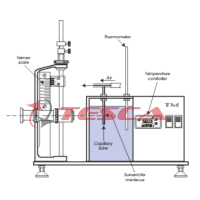

The apparatus consists of a rotating drum calorimeter containing a fixed quantity of water in it. The calorimeter can be rotated using a pulley and a toothed belt driven by a variable speed DC motor. Mechanical energy is dissipated by friction between the rotating drum calorimeter and the brake band wound around it. The mechanical energy dissipated is measured using the spring dynamometer- weight hanger system. The equivalent heat energy generated because of the dissipation of mechanical energy is measured by the increase in temperature of the calorimeter and the water contained in it. Thus, the mechanical equivalent of heat can be determined. The apparatus is compact, rugged and robust and is mounted on a moveable platform. This apparatus can also be used to determine the thermal capacity of the calorimeter or the specific heat of the calorimeter material by assuming the equivalence of the mechanical work and the heat energy

Important Components and Specifications:

Variable speed DC motor with speed regulation. 0.5 KW, 500 RPM.

Rotating Drum Calorimeter driven by pulley and toothed belt, Internal diameter 150mm, length 150mm and made of copper.

Dynamometer, brake band with mass hanger and spring balance, capacity = 10 kg.

Mercury thermometer, 0 –600 range, accuracy = 0.10.

Mechanical revolutions counter with zero setting.

Standard weights, 1 kg. (5 Nos.), 5 kg. (1 No.)

Stop watch, digital and 1/100 sec. resolution.

Power supply and control panel.

Measurements

Spring dynamometer-mass hanger readings to determine brake band tension.

RPM of rotating drum calorimeter.

Mechanical energy dissipated.

Temperature rise from thermometer measurements.

Heat energy generated.

Experiments

- Study of the basic aspects of conversion of mechanical work to heat energy.

- Familiarization with the working of the apparatus.

- Measurement of mechanical work dissipated and heat energy dissipated.

- Determination of mechanical equivalent of heat.

- Determination of thermal capacity of calorimeter assuming equivalence of mechanical work and heat.

- Determination of specific heat of calorimeter material assuming equivalence of mechanical work and heat. The manual describing the theoretical and practical aspects of the apparatus, operation and analysis of results and esti mation of errors will be supplied with the equipment.

Services Required

Electrical Supply, 220-240 V Single-phase.

Overall Dimensions

500 x 800 x 1000 mm.

91-9829132777

91-9829132777