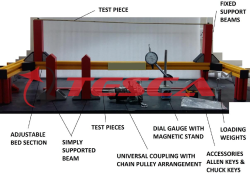

Coupling Shaft Alignment Trainer

Order Code: 32126

Category: Strength of Materials Lab

Features: Heavy-duty, aluminum construction throughout. The overall weight of 20Kgs excluding packaging. Allows for alignment using all common alignment methods. Multiple "motor" positions allow for use of all ...

SPECIFICATION

Features:

- Heavy-duty, aluminum construction throughout.

- The overall weight of 20Kgs excluding packaging.

- Allows for alignment using all common alignment methods.

- Multiple "motor" positions allow for use of all common couplings including "spacer-type" couplings.

- Based on a standard centrifugal pump configuration, it has the "look" and "feel" of real equipment.

- Rigid, heavy-duty construction allows alignment to .001".

- Requires a minimal number of tools.

- Movable flanged bearings allow for the variation of angular and parallel misalignment in all directions.

- All fasteners are easily accessible and replaceable.

- Steel threaded inserts at motor hold-down bolt locations.

- Replaceable shaft. Bent shafts are easily installed.

- Uses inexpensive size "A" shims.

- High-durability urethane coating allows for repeated use and rough handling.

- Provision for motor adjustment via jacking bolts.

- All components can be mounted on the ‘Tesca’ Electromechanical Integration Bench

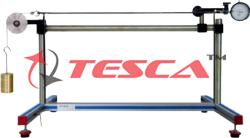

Tesca Coupling/Shaft Trainer is a lightweight, yet stable, fully functional fixture that allows for convenient classroom training in precision shaft alignment.

Welded aluminum construction and careful hardware selection combine to create an accurate, durable device for use with all varieties of alignment equipment, including laser alignment systems.

Available for immediate delivery, this teaching aid will make your next training session more productive, realistic, and professional.

Technical Specification:

1. Driver and driven elements made of heavy-duty metal.

2. Flanged bearings allow for changes in angular and parallel misalignment and allows alignment to 0.001" (max)

3. Shaft dimensions based on a common ANSI centrifugal pump

4. Driver element position adjustable to allow for the use and alignment of the following couplings:

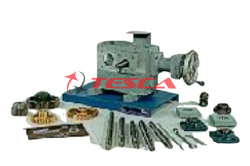

a) Gear type coupling (Qty: 1 unit each) I

b) Steel grid coupling (Qty: 1 unit each)

c) Jaw and spider coupling (Qty: 1 unit each)

d) Elastomeric element coupling (Qty: 1 unit each)

5. Approximate dimensions (LxWxH): 900 x 330 x 400 in mm

Accessories Supplied:

1. One Set tool kit

2. Metal frame workbench of work suitable height. The trainer base must be bolted onto the workbench. A storage shelf provided.

3. One set shim/fit plate kit per trainer consisting of 20 each of different thickness of size A stainless steel shims.

4. 1 set Exercise Procedure on Alignment per trainer.

5. CD/DVD per trainer on the following topics:

a. Reverse double dial alignment procedures.

b. Alignment using rim and face method.

c. Use of dial indicators.

6. Magnetic base dial indicator

91-9829132777

91-9829132777