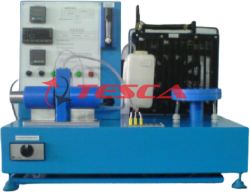

Batch Distillation Column

Order Code: 32393

Category: Thermodynamics Lab

Distillation is used to separate liquid mixtures made up of individual liquids that are soluble in one another. Batch Distillation Column 32393, in its different versions, is one of the most powerful laboratory tools for the study of the variables t...

SPECIFICATION

Distillation is used to separate liquid mixtures made up of individual liquids that are soluble in one another.

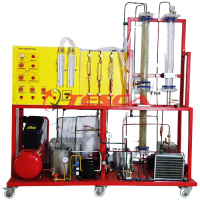

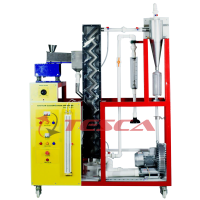

Batch Distillation Column 32393, in its different versions, is one of the most powerful laboratory tools for the study of the variables that affect the distillation process. The student can investigate the principles that rule the mass and energy transference, as well as determine the optima operation point to carry out a big quantity of separations. It is basically composed by a boiler on which two types of interchangeable columns can be adapted (plate columns and Raschig Rings column), a reflux system and a tank for the distillation. The steam that goes to the head of the column is sent to a total condenser. The cooling water flow that crosses the condenser is regulated and indicated in a flow meter. The pressure loss in the column can be measured with a manometer.

The temperatures of the system are measured by temperature sensors placed in strategic positions.

Specifications

Anodized aluminum frame and panels made of painted steel.

Main metallic elements made of stainless steel.

Diagram in the front panel with distribution of the elements similar to the real one.

Sieve Plates Column with 8 plates with one temperature taking and sample, 50 mm internal diameter and 1000 mm. length. Vacuumed, Silver plated and double transparent band for vision.

Column head with temperature taking and conical output for distilled product.

Column head with a valve for the steam distribution. Ÿ 2 l Boiler (with sample outputs) with heating mantle. Ÿ 2 l Distillation collector of graduated glass.

Refrigerator.

Temperature measurement system.

Seven temperature sensors ”J” type.

Working temperature: ambient temperature up to 125 °C.

Flow meter, range: 0.2 – 2 l/min.

Manometer tubes.

Solenoid valve.

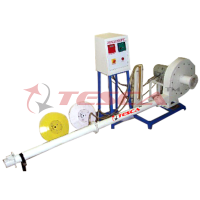

Electronic console:

Metallic box.

Temperature sensors connections.

Digital display for temperature sensors.

Selector for temperature sensors.

Heating element (heating mantle) temperature control.

Solenoid valve switch.

Solenoid valve timer controller. (Solenoid valve reflux time control).

Optional Columns (Not included in the standard supply):

CAR1. Raschig Rings Column.

C8P8. 8 Plates Type Column (8 Temperature points).

C10P10. 10 Plates Type Column (10 Temperature points).

C14P14. 14 Plates Type Column (14 Temperature points).

Experiments

Preparation of solutions.

Analytic valuation techniques.

Filling of the column.

Batch operation.

Obtaining the McCabe-Thiele diagram. Without reflux.

Obtaining the number of plates. Without reflux.

Efficiency calculations. Without reflux.

Variation of the composition of the distilled product: constant reflux ratio.

Constant composition of the distilled product: variation of reflux ratio.

Constant composition of the distilled product: constant reflux ratio.

Mass and energy balances across the system.

Plates fluid dynamics studies, including load loss and column flooding.

Calculation of the theoretical number of floors in the plates columns, and the equivalent height of the theoretical floor in the Raschig rings columns.

Pursuit of the temperatures in all plates in the column (Plates columns).

Study of the rectification efficiency.

Demonstration of azeotropic distillation.

Studies of heating interchange in glass refrigerators

Required Services

Water Supply.

Drain.

Electricity Supply: 1 Phase, 220 V AC, 0.5 kW.

Water/Methanol.

Heptane/Methylcyclohexane.

P-Xylene/Methylcyclohexane

91-9829132777

91-9829132777