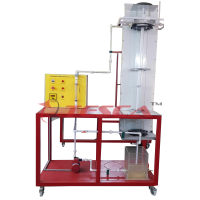

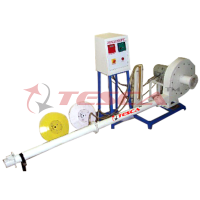

Forced Air Gas Burner Trainer

Order Code: 32289

Category: Thermodynamics Lab

There are different machines and types of devices in the heat generation field, both at industrial and domestic level, used to heat from tap water to solids and some gases. This type of devices uses different heat generation systems, from electric sy...

SPECIFICATION

There are different machines and types of devices in the heat generation field, both at industrial and domestic level, used to heat from tap water to solids and some gases. This type of devices uses different heat generation systems, from electric systems to combustion with different types of fuels: paraffin, diesel oil, pellets, coal and gas, among others.

Forced air gas burners have a powerful fan inside that ensures the exhaust of the combustion gases to the outside. This system is safer and allows the heater installation in confined or poorly ventilated spaces. It is important to study and understand this system in order to carry out the repair of faults in domestic installations.

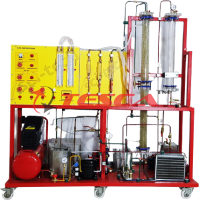

Tesca Forced Air Gas Burner, is a compact teaching unit with wheels to facilitate its mobility. It represents a controlled gas system that supplies a forced air gas burner. It allows the study of the arrangement, measuring elements and safety devices required by a forced air gas burner system. The unit works with air, simulating the operation of the burner, so it can be safely used in a classroom or laboratory. It includes a compressor that supplies the air required to work with the unit.

The main element of the unit is a commercially available forced air gas burner that includes the required safety systems: gas pressure, flame detection, thermostat, pressure switch, flame safeguard, etc. All the states of the burner and the sequences of the burner start control can be displayed in a front panel with LEDs and, thus, monitor the burner flame safeguard service. The unit allows for regulating the supply gas flow with a pressure stabilizer and the intake gas flow to the burner through a control valve, as well as setting the nominal load of the burner and calculating the gas flow rate and operating volume. The unit includes a flow meter and a real gas meter for those purposes. There are analog manometers and tube manometers to observe the most important operating pressures.

The unit has white background in the back side that allows the selection of errors in the burner sequence, programming it to simulate these errors when it is started. With this system the student can observe the different breakdowns and learn how to identify them.

The unit can be used by several students at the same time. They can act on the elements of the line; carry out maintenance and tune-up operations and fault finding and repair.

Detailed Operation & Maintenance Manual is provided along with the trainer.

Technical Specifications:

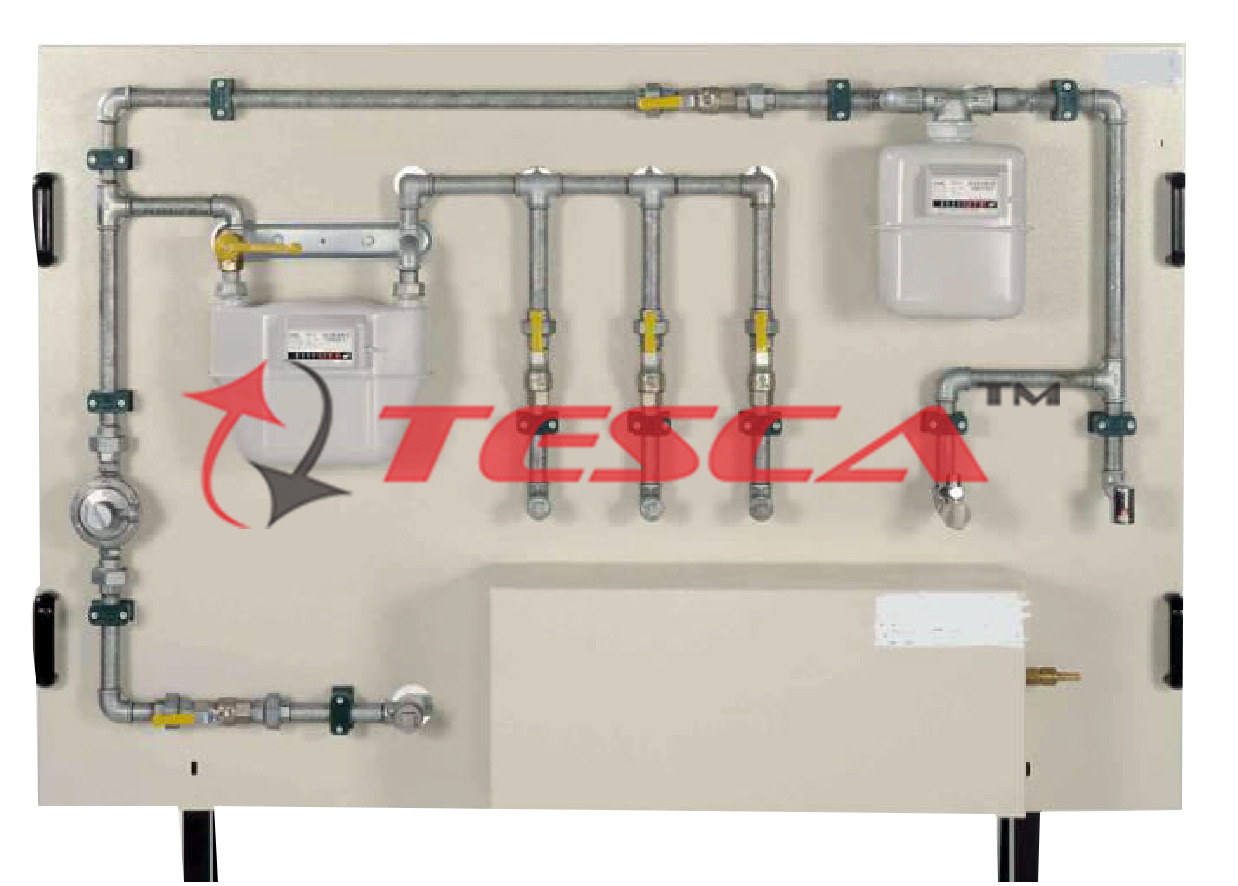

Components of the gas line:

Relief valve.

Pressure stabilizer.

Home gas meter. Maximum flow: 6 Nm³/h.

Flow control valve.

Compressor:

Diaphragm pump. Power: 62 kW.

Maximum flow rate: 95 l/min.

Maximum pressure: 0.4 bar.

Gas burner:

Forced air gas burner. Thermal power: 5 – 45 kW.

Inlet valve of the gas burner.

Forced air fan.

Flame detector.

Thermostat.

Air minimum pressure switch.

Gas minimum pressure switch.

Measurements:

Pressure manometers:

Analog manometer and tube manometer in the gas line.

Analog manometer and tube manometer in the gas burner inlet.

Tube manometer for minimum inlet pressure.

Air flow meter. Range: 0 – 35 l/min.

Additional tools:

Flat-blade screwdriver to regulate the pressure regulator.

Star screwdriver to regulate the pressure switches.

Cables and Accessories, for normal operation.

Experiment Possibilities

1. Identification and management of the components required for a real gas line.

2. Study and analysis of the tune-up operations for the forced air gas burner.

3. Study of the ignition procedure and the nominal load adjustment of a gas burner.

4. Study and analysis of the gas flow rate and the operating volume.

5. Substitution procedure of the main components for a real gas line.

6. Faults study, analysis and repair.

Services Required

Electric Supply 230 V AC, 16 A, Single Phase, Earthed.

91-9829132777

91-9829132777