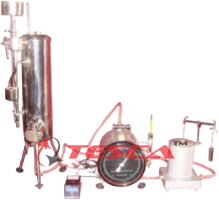

Fluidization & Fluid Bed Heat Transfer Unit

Order Code: 32394

Category: Thermodynamics Lab

Features Safe and Suitable For Unsupervised Student Operation Responds Rapidly to Control Changes Negligible Operating and Maintenance Costs Optional Computerised Data Acquisition Upgrade. Fluidization & Fluid Bed Heat Transfer Unit 32394...

SPECIFICATION

Features

Safe and Suitable For Unsupervised Student

Operation

Responds Rapidly to Control Changes

Negligible Operating and Maintenance Costs

Optional Computerised Data Acquisition Upgrade.

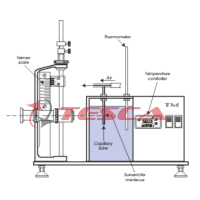

Fluidization & Fluid Bed Heat Transfer Unit 32394 has been designed to provide visual and quantitative results related to the flow of air through both a packed and fluidized bed of granular material contained in a vertical glass cylinder. At the lower end of this is a distribution chamber and air distributor which supports the bed when de-fluidized. Probes for temperature and pressure measurement, and a horizontal cylindrical heater, can all be moved vertically to any level in the bed chamber. Air from a local compressed air supply is delivered through a filter/pressure regulator, an air flow meter fitted with a control valve and an orifice plate (to measure higher flow rates), to the distribution chamber. When in use, the heat transfer rate from the heater is adjusted by a manual electronic control, and digitally displayed. Two thermocouples are embedded in the surface of the element. One of these indicates the surface temperature, and the other, in conjunction with a controller, prevents the heater surface temperature exceeding a set value (up to 200°C). A digital temperature indicator with a selector displays the temperatures of the element, the air supplied to the distributor, and the moveable probe in the bed chamber.

Two liquid filled manometers are fitted. One displays the pressure of the air at any level in the bed chamber, and the other displays the orifice differential pressure, from which the higher air flow rates can be determined. Four grades of Fused Alumina (Aluminum Oxide) Loose Grain are supplied with the unit and these are suitable for a wide range of fluidization and heat transfer experiments.

An important feature of this unit is the ease with which the bed material may be changed. The unit can be in operation again in two or three minutes.

Specifications

Granular Material: Fused Alumina

Four Grades of granules supplied

Bed Chamber: Ø105 x 220mm long

Panel: High quality impact resistant plastic on which the following components are mounted:

Electronic Control to adjust the heater power input.

Digital Wattmeter to indicate the heater power input. Range 0 to 1000W (Heater power nominally 400W)

Flow Meters to measure air flow through bed. Range 0.15 to 3.5 litres/sec.

Digital Thermometer to indicate the temperatures of heater surface, air inlet and probe. Resolution 1°C.

Manometer to measure pressure drop through bed.

Safety Features include overload cut out and grounding of all components and heater temperature controller.

Experiments

Observation of the behaviour in fluidized bed of a wide range of granular materials, from onset of fluidization to entrainment.

Measurement of air flow and pressure drop through a variety of granular materials, as packed and as fluidized beds.

Investigation of the effect of distributor design on bed behaviour.

Investigation of the effect of Superficial velocity; depth of immersion; particle size on the surface heat transfer coefficient for a hot surface in a fluidized bed.

Demonstration of separation by particle size and density.

Required Services

Electricity Supply: 1 Phase, 220 V AC, 0.5 kW.

91-9829132777

91-9829132777