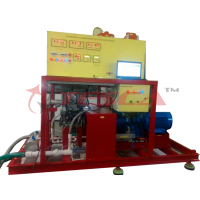

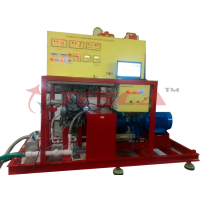

For Diesel Engine

Order Code: 32721

Category: Technology Trainers

Features Designed for comprehensive analysis of performance of different automobile engines. Digital Instruments for measurement of parameters like fuel consumption, air flow, temperature and RPM etc. Demonstration of performance of Petrol & D...

SPECIFICATION

Features

Designed for comprehensive analysis of performance of different automobile engines.

Digital Instruments for measurement of parameters like fuel consumption, air flow, temperature and RPM etc.

Demonstration of performance of Petrol & Diesel; Engines at different throttle settings & Loads.

Optional dedicated ‘Diesel Engine’ or ‘Petrol Engine’ trainers available.

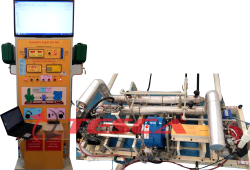

Optional High Speed Data Acquisition system for performance monitoring.

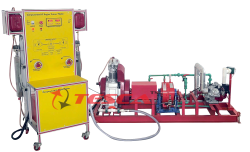

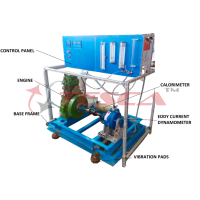

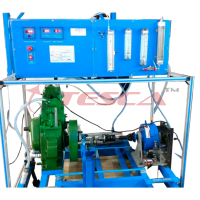

Single Cylinder Petrol and/or Diesel Engine Test Bed Order Code : 32719 designed to felicitate testing of different automobile engines. The test bed is complete with eddy current dynamometer and measuring instruments for measuring key engine parameters required for performance analysis of an engine. The test bed can be used for testing of both petrol & diesel engines of passenger cars, rated up to 80 kW.

The test bed consists of a water cooled eddy current dynamometer fixed on a heavy-duty steel frame. The test bed is designed in such a way that the engine to be tested can be quickly coupled to the dynamometer with minimum effort. The test bed is equipped with dynamometer control panel with necessary safety instruments. The Engines can be used for performance tests for different loads and speeds under various throttle opening conditions. The eddy current dynamometer provides a variable load on the engine, allowing the characteristic power and torque curves to be reproduced in the laboratory. The system comes complete with extensive instrumentation, including rpm measurement, torque (from which power can be calculated), plus various temperatures, Fuel Consumption, Air Consumption. Different optional accessories are available to integrate with the Engine Test Bed for comprehensive engine performance analysis. These include the exhaust gas calorimeter (For Heat Balance Sheet), advance Data

Specifications

Hydraulic Dynamometer: Capacity @ 10KW, Water Cooled (Optional) Eddy Current Dynamometer:

Water Cooled Eddy Current Dynamometer

Maximum Power: 10BHP @1500 rpm to 3000rpm

Maximum RPM 1500 to 8000rpm

Dynamometer Controller

Engines: Single Cylinder Four Stroke Petrol Engine

Air Cooled, Spark ignited, recoil start

Power Output: 8.7 kW (13 HP)

Maximum Torque: 20Nm @ 2500 rpm

Displacement: 589 cm3

Bore: 100 mm

Stroke: 75 mm

Compression Ratio: 8.2:1

Engine mounted on frame

Single Cylinder Four Stroke Diesel Engine

Air Cooled, compression ignition

Output: 6HP @ 3600rpm

Torque: 25 Nm @ 1500 rpm

Displacement: 665 cm3

Bore: 87.5 mm

Stroke: 110 mm

Note: Other Single Cylinder Engines can be supplied on request.

Calorimeter

Water Flow-rate Transmitter

Wheel type

Range: 0-2000 LPH

Output: 4-20mA

Load cell

Strain gauge type

‘S’ type

Range: 0 to 150 kg

Output: 3 mV/V

Operating mode: Compression/Tension

Threading: M10

Load cell transmitter

Range: 0 to 250 Nm

Output: 4 to 20 mA

Differential Pressure Transmitter

Range: 0 to 255mmWC

Output: 0 to 10v DC

Air velocity Transmitter

Range: 0 to 10m/s

Output: 0 to 10V DC

Level Sensor

Range: 0 to 420mm

Output: 4 to 20mA

Temperature Sensors:

Type: Resistive Type

Model: Pt100

Software which stores all data and formulae for calculations, as well as record on excel sheets the accurate data as well as readings for the purpose of calculations.

DAQ device

Analog Channels: 16 nos

Digital Channels: 45 nos

Air Box with Orifice plates for Air flow measurement.

Coupling: Either Engines can be coupled at a time to the Hydraulic Dynamometer or Eddy

Current Dynamometer

Fuel Tank: Two separate tanks, each for Petrol & Diesel.

Propeller shaft with protective covering.

Measuring Instruments, (Optional) Sensors & Transmitters –

Engine Digital RPM Meter or Optional Sensor & RPM transmitter

Calorimeter (Optional)

Water Flow rate Analogue or Optional Sensor based transmitter

Optional Pressure Transmitter Sensor (P-Theta & P-V arrangement)

Optional Encoder (P-Theta & P-V arrangement)

Fuel Level Meter or Optional Sensors

Optional Fuel Cell transmitters

Temperature Indicator or Optional Sensors

Optional Torque Sensor

Load Cell

Optional Load Cell transmitter

Air Flow Measurement Meter or Optional Sensors & Transmitters

Optional ‘Data Acquisition Software with necessay Sensors

Optional Data Interface Modules: a) Fast ADC b) Slow ADC

Data Communication

RS485 to USB Converter

CD/DVD containing:

DAQ Software

Accessories

Battery for starting the engines (Optional)

Set of Anti Vibration Pads(Optional)

Optional Auxiliary cooling unit for engine

Exhaust Gas Calorimeter (Optional)

Cooling Water Flow Transmitter

Pipe In pipe type heat exchanger

Thermocouples for water & gas temperature.

DAQ based Software (Optional)

Signal Converters

P-V Diagram Module (Optional)

Engine cylinder pressure

Crank angle Encoder

Experiments

Investigate Engine Performance at different Throttle Settings & Load conditions.

Calculation of Mechanical Efficiency & Plot brake power versus mechanical efficiency.

Measurement & Calculation of Volumetric efficiency.

Measurement & Calculation of specific fuel consumption

Measurement & Calculation of brake thermal efficiency

Determining air / fuel ratios

Heat Balance Test (With Optional Exhaust Gas Calorimeter)

Study of P- q & P – V Diagram for Engine (With

optional P-V Module & Data Acquisition System).

91-9829132777

91-9829132777