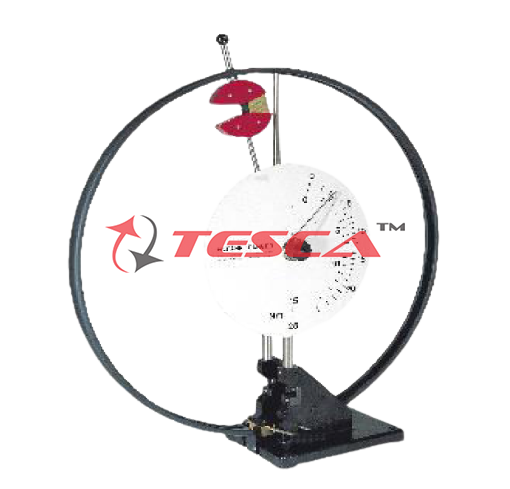

Impact Test Apparatus

Order Code: 32215

Category: Strength of Materials Lab

Features Charpy notched-bar impact test classic method from destructive materials testing for quality control and analysis of the fracture behavior of metallic materials In the field of industrial quality control, the i...

SPECIFICATION

Features

- Charpy notched-bar impact test

- classic method from destructive materials testing for quality control and analysis of the fracture behavior of metallic materials

- In the field of industrial quality control, the impact test is a widely used test method with which to quickly and easily determine characteristics for a material or component analysis.

Tesca Impact Test Apparatus experimental unit is a solid-pendulum impact tester, designed for the Charpy notched-bar impact test. The clean layout and simple operation mean the experimental sequence can be observed in all details and phases.

In the experiment, the hammer attached to a pendulum arm describes an arc. At the lowest point of the hammer path, the hammer transfers part of its kinetic energy to the notched specimen. The specimen is either destroyed or bent by the impact and pushed between the supports.

The notched-bar impact work required to deform the specimen is read directly off a large scale.

In order to vary the output energy, the mass of the hammer can be changed by adding or removing weights.

A brake reduces the residual energy of the hammer on each swing until it reaches zero. A protective ring ensures the experiments can be conducted safely while also fixing the hammer in place. The hammer is triggered with two hands for safer operation.

The experimental results allow quality control and an analysis of the fracture behavior of different metallic materials. Non-metallic specimens can also be used. Specimens with different notch geometries, in different materials and specimen dimensions are included in the scope of delivery.

Specifications

Classic Charpy notched-bar impact test

Pendulum impact tester

Hammer mass can be varied by adding or removing weights

Brake to reduce the residual energy

Safe operation thanks to two-hand release of the hammer and protective ring for the operating area

Protective cover available as an accessory

Scale for displaying the notched-bar impact work

Notched-bar impact specimens: aluminium, copper, steel, brass

Optional System for data acquisition

Technical Specifications

1. Pendulum impact tester

? Work capacity

? 15Nm

? 25Nm (with extra weights)

? Hammer

? weight: 2,05kg and 3,42kg (with extra weights)

? Extra weights: 4x 0,342kg

? Impact velocity: 3,8m/s

? Head: 745mm

2. Supports for specimens

? Gap: 40mm

3. Notched bar impact specimens

? LxW: 10x5mm, 10x10mm

? Cross-section at the notch root: 10x8 and 10x5mm

3. Specimen materials

? Automotive steel 9SMn28K

? Tempering steel C45k

? Structural steel S235JRC+C

? Brass CuZn40Pb2

Experiments

- Determine the notched-bar impact work

- Determine the notched-bar impact strength

- Analyze the fracture surface characteristics

- Plot a notched-bar impact work–temperature diagram

- Influence of notch shape, material and specimen temperature on the notched-bar impact work

91-9829132777

91-9829132777