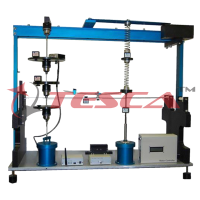

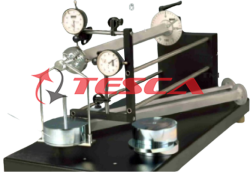

Pressure Distribution In Journal Bearing Apparatus

Order Code: 32154

Category: Strength of Materials Lab

The field of tribology covers all forms of friction. Dry, mixed, and fluid friction all occur in journal bearings. Under operating conditions, there is completely distinct fluid friction, so that the shaft and bearing shell are separated by a support...

SPECIFICATION

The field of tribology covers all forms of friction. Dry, mixed, and fluid friction all occur in journal bearings. Under operating conditions, there is completely distinct fluid friction, so that the shaft and bearing shell are separated by a supporting lubricating film. The supporting function of the lubricating film can be described by the pressure distribution in the bearing gap.

Tesca Pressure Distribution in Journal Bearing Apparatus is used to visualize the radial pressure profile in the journal bearing with hydrodynamic lubrication.

To this end, the experimental unit contains an open bearing shell that only encloses a shaft halfway and which simulates the journal bearing. The bearing shell is secured to two spring plates in such a way that it can be moved. Unlike real hydrodynamic journal bearings, the gap width can be adjusted via the radially moveable bearing housing by means of the spring plates and a micrometer screw.

The experimental unit is quickly and easily mounted on the frame of the drive unit with quick-action chucks. The shaft is driven by a clamp coupling between the drive unit and the gear unit. The display and control unit of the drive unit shows frictional force and speed and allows the continuous adjustment of the speed.

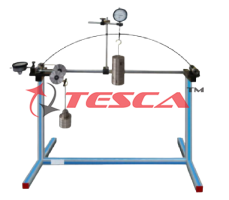

There are 13 measuring points around the circumference of the bearing shell to measure the pressure. The pressures are read off from 13 to 15 tube manometers using the height of each column of liquid. The lubricant is supplied via an oil pan. The bearing shell is transparent, allowing close observation of the experiment.

Specifications

Demonstration and visualization of the pressure distribution in a journal bearing with hydrodynamic lubrication

Quick and easy assembly of the experimental unit on the frame of the drive unit

The roller is driven by a clamp coupling between the drive unit and gear unit

Bearing housing is completely transparent

Moveable bearing housing, the adjustable bearing gap

13 radial pressure measuring points on the bearing shell

Radial pressure distribution indicated with 13 to 15 tube manometers

Technical Specifications

Shaft

- Diameter: 50mm

- Length: 50mm

- Material: stainless steel

Bearing shell

- Diameter: 52,5mm

- Bearing gap adjustable from: 0…2,5mm

- Adjustment mechanism for bearing shell

- Graduation: 0,01mm

Oil

- ISO viscosity grade: VG 32

Measuring ranges

- Pressure: 360mm oil column

- Speed: 0…200min-1

Experiments

- Pressure distribution in the journal bearing depending on the speed

- Pressure distribution in the journal bearing depending on load or bearing gap width

- Stability limit as a function of the gap width

91-9829132777

91-9829132777