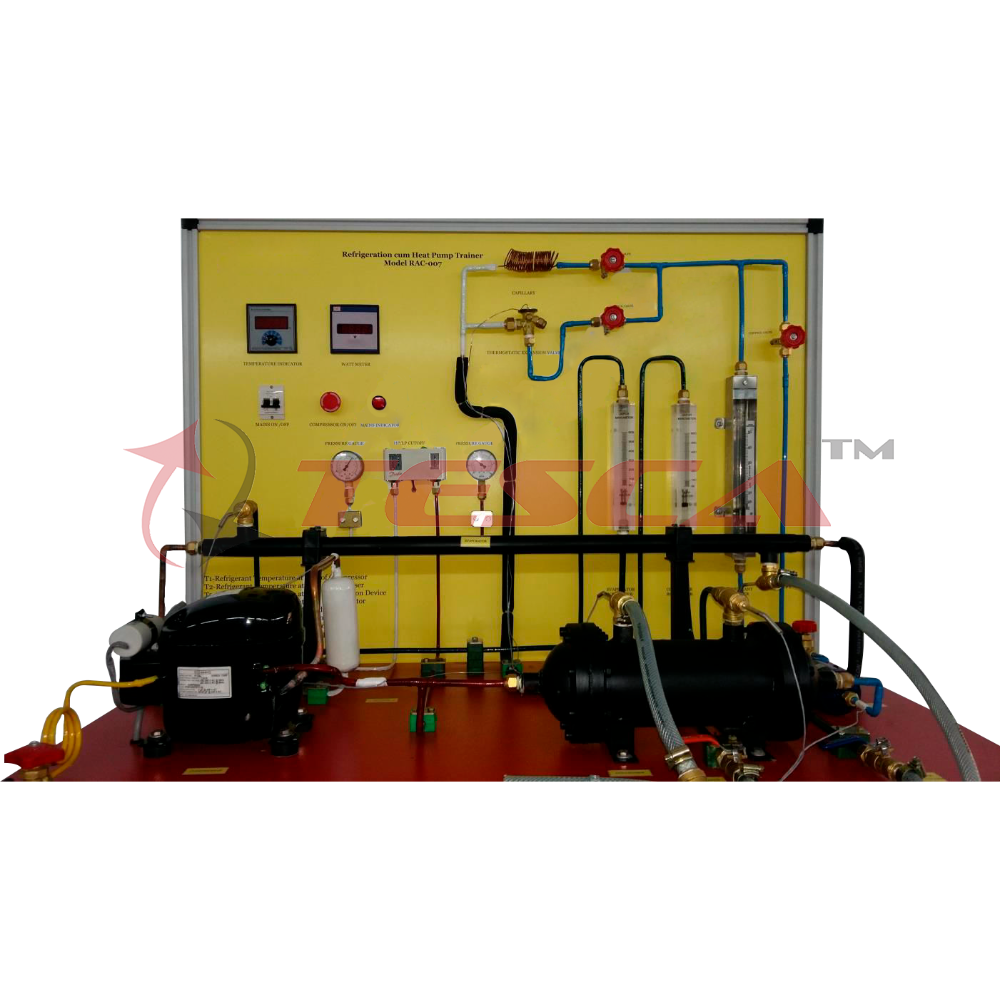

Refrigeration Cum Heat Pump Trainer

Order Code: 32401

Category: Refrigeration & Air Conditioning Lab

Tesca Refrigeration cum Heat Pump Trainer 32401 is designed to provide students with a thorough understanding of various types of systems used in commercial and industrial applications. It permits students to understand the refrigeration cycle, inclu...

SPECIFICATION

Tesca Refrigeration cum Heat Pump Trainer 32401 is designed to provide students with a thorough understanding of various types of systems used in commercial and industrial applications. It permits students to understand the refrigeration cycle, including measurement of pressure, vacuum, flow rate and temperature.

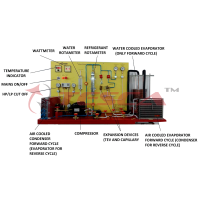

The unit contains a reversing valve so that the system may be run as a heat pump in addition to operation as a refrigeration system.

Sight glasses at inlet and outlet of evaporator and condenser allows students to monitor changes in refrigerant state.

The system components are panel mounted to provide easy access for testing and troubleshooting.

List of Experiments

- Basic skill training

- Basic function of refrigeration control components, such operating principles and common fault & trouble shooting method

- Learn the sizing of condenser, evaporator and compressor units

- Troubleshooting of refrigeration cycle failure symptom and caused

- Basic electric control circuit and system of common air conditioning system

- System Setup: initial leak detection, leak detection, evacuating a refrigerant

- Study on receiver: liquid receiver and suction line accumulator

- Familiarization with various types of compressor

- Investigation on the operation of the compressor

- Familiarization with the operating of metering devices, for instance, thermostatic expansion valve, automatic expansion valve, capillary tube

- Study on system control devices such as pressure controllers, thermostatic controls, solenoid valve controls and backpressure regulator

- Study on the principles of evaporator and condenser – superheating and sub cooling, heat exchanger

- Investigation of refrigeration system

- Learn to use a pressure-enthalpy chart

- Determine superheat and sub-cooling

- Basic refrigeration cycle energy balance

- Determine coefficient of performance (CoP)

- Determine non-isentropic, isentropic and volumetric efficiencies of the compression stage

- Effect of heat source and heat sink temperatures on CoP

- Compare performance between actual and reversed Carnot cycles

Technical Specifications

Compressor

- Hermetic : 450 Watt

- Refrigerant : R-134A

- Voltage : 240

Condenser

- Forced air coil with variable speed fan

Control devices

- Low pressure switch

- High pressure switch

- Back pressure regulator

- Capillary tube

- Automatic expansion valve

- Thermostatic expansion valve

- Solenoid valves

- Thermostatic controller

- Flow Meter

- Wattmeter, Voltmeter, Ammeter

- Thermometer

Safety features

- Safety pressure switch

- Main breaker switch

- Compressor breaker switch

Evaporator

- Air Cooled Type

- Water Source Type

Optional ‘Sci-Cal’ Tesca software for data

acquisition via USB under Windows 7, 8.1, 10

Optional

‘Sci-Cal’ Computer Control Software

PID Computer Control + Data Acquisition + Data Management.

Compatible with actual Windows operating systems. Graphic and intuitive simulation of the process in screen. Compatible with the industry standards.

Registration and visualization of all process variables in an automatic and simultaneous way.

Flexible, open and multi-control software, developed with actual windows graphic systems, acting simultaneously on all process parameters.

Analog and digital PID control.

Menu for PID and set point selection required in the whole work range.

Management, processing, comparison and storage of data.

Sampling velocity up to 250 KS/s (Kilo samples per second).

Calibration system for the sensors involved in the process.

It allows the registration of the alarms state and the graphic representation in real time.

Comparative analysis of the obtained data, after the process and modification of the conditions during the process.

Open software, allowing to the teacher to modify texts, instructions. Teacher’s and student’s passwords to facilitate the teacher’s control on the student, and allowing the access to different work levels.

This unit allows the 30 students of the classroom to visualize simultaneously all results and manipulation of the unit, during the process, by using a projector or an electronic whiteboard.

This module requires Control Interface Module and Data Acquisition.

Interface In-built Module:

This control interface is common for the ‘Sci-tech’ trainers and can work with one or several trainers.

The Control Interface is part of the SCADA system.

Control interface with process diagram on the front panel.

The unit control elements are permanently computer controlled.

- Simultaneous visualization in the computer of all parameters involved in the process.

- Calibration of all sensors involved in the process.

- Real time curves representation about system responses.

- All the actuators’ values can be changed at any time from the keyboard allowing the analysis about curves and responses of the whole process.

- Shield and filtered signals to avoid external interferences.

- Real time PID control with flexibility of modifications from the computer keyboard of the PID parameters, at any moment during the process.

- Real time PID control for parameters involved in the process simultaneously.

- Proportional control, integral control and derivative control, based on the real PID mathematical formula, by changing the values, at any time, of the three control constants (proportional, integral and derivative constants).

- Open control allowing modifications, at any moment and in real time, of parameters involved in the process simultaneously.

- Three safety levels, one mechanical in the unit, another electronic in the control interface and the third one in the control software.

Scope of Delivery

Operating instructions, Student experiment book, Teacher's answer book.

91-9829132777

91-9829132777