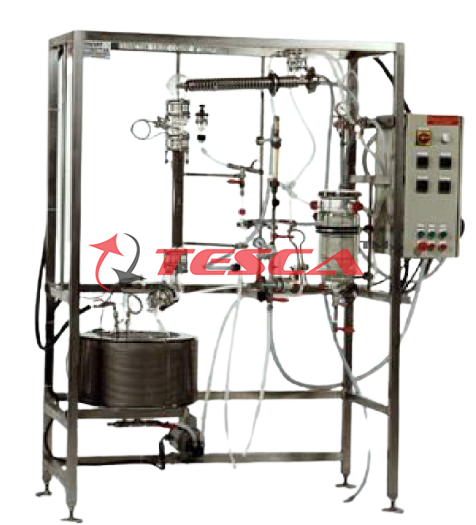

Solid Liquid Extraction Unit

Order Code: 32300

Category: Thermodynamics Lab

Recommended material Optional data logging accessory with USB interface and educational software Tesca Pilot Plant for Solid/Liquid Extraction Unit is a continuously rotating extraction cell divided into compartments. The raw material is fed into...

SPECIFICATION

Recommended material

Optional data logging accessory with USB interface and educational software

Tesca Pilot Plant for Solid/Liquid Extraction Unit is a continuously rotating extraction cell divided into compartments. The raw material is fed into these compartments from the input hopper using a screw feeder mechanism. The material is then passed under three solvent sprinkler bars, one for each stage of the process, and the dissolved product is captured in three drainage compartments. Pumps are provided to pump the product from the drainage compartment of one stage to the sprinkler of the next stage. At the end of the process the spent carrier material is dropped into a collection vessel, assisted by water sprayed from above.

The system is configured as a continuous three-stage, counter-current flow process, but may also be configured as a one or two-stage process for teaching purposes.

Full temperature control is provided at each stage of the process using the three integrated PID controllers and related heating elements.

Features

Self-contained floor standing unit with integral control and instrumentation console

Three-stage continuous extraction process, can also be configured as one or two stages

Independent vessel for closed-loop batch extraction

Temperature control at each stage

Individual control of solvent feed pumps at each stage, of cell rotation rate and of feed rate

Probes at each stage allow full monitoring of the process

With the data logger, the product concentrations can be directly displayed in real-time (for the

Direct control is also provided over the product feed rate, the cell rotation speed and the inter-stage pump speeds.

In addition to the rotary cell, an independent vessel is provided which enables batch extractions to be performed.

The unit is fully instrumented with each stage of the process equipped with sensors, giving a temperature and a millivolt (mV) conductivity probe output. When using the standard water/potassium bicarbonate system, the sensor readings can be related to the percentage weight of potassium bicarbonate in the solution using experimental data.

All temperatures and voltage outputs from the conductivity sensors, together with the feed, extractor cell and individual pump rates can also be displayed directly on a computer using the optional data logging interface. Using the interface, it is also possible to display and log the product concentration (when using the recommended

material).

The equipment is designed to teach all relevant aspects of solid/liquid extraction in a simple and safe manner. It does not require the use of toxic, volatile or flammable solvents, as it is designed to use water or water-based solvents.

This ensures the process is fully visible to students, enabling them to observe and understand the details of the operation at every stage.

There is no need for expensive solvent recovery equipment, such as a distillation column. The solid carrier is a light porous material, a quantity of which is supplied with the equipment. It can be impregnated with a salt such as potassium bicarbonate or sodium bicarbonate, which is then extracted by the process. The use of a salt enables real-time monitoring of the process using the sensors and instrumentation. The carrier material is reusable.

The entire set up is mounted on a wheeled stainless steel structure.

Detailed Operation & Maintenance Manual is provided along with the trainer.

multiple-stage process

Closed-circuit percolation extraction (batch extraction)

Open-loop percolation extraction (continuous operation)

Extraction of chorophyl from spinach with ethanol

Extraction of oil from soybean laminate with hexane

Extraction of starch from potatoes with water

Calculation of the number of theoretical stages

Process Calculations for costing purposes

Mass Balances

Services Required

Electric Supply 230 V AC, Single Phase, Earthed.

Cooling Water: Cold water supply & Drain.

Specifications

Wheeled structure of AISI 304 stainless steel, piping and valves of AISI 304 and AISI 316 stainless steel

Borosilicate glass extractor, DN 100-200, I 1000 mm, with PTFE Archimedean screw

Tank of borosilicate glass for storing the solvent with capacity of 10 I approx.

AISI 304 stainless steel hopper with capacity of 2 L, for storing the solid

AISI 304 stainless steel condenser, exchange surface of 0.1 m²

Tank of borosilicate glass for storing the extracted phase with capacity of 10 I approx.

Tank of borosilicate glass for storing the exhausted solid with capacity of 10 I approx.

Metering pump for the solvent

Geared motor foe solid feeding Archimedean screw with speed of 0 to 20 r.p.m

Geared motor for the Archimedean screw of the extractor with speed of 0 to 10 r.p.m

2 programmable timers for controlling the start and stop times of the Archimedean screw

3 Pt 100 thermoresistances

3 temperature electronic indicators

Thyristor unit for controlling the heating power

Electric heater of quartz for solvent pre-heating, p=0.4 kW

LabVIEW software for data acquisition via USB under windows XP or Windows Vista

Switchboard IP55, complying with EC standard. Inclining plant synoptic, ELCB and emergency pushbutton

Experiment Capabilities

Study of the extraction performance according to different variables

Demonstration of the operation of a continuous

91-9829132777

91-9829132777