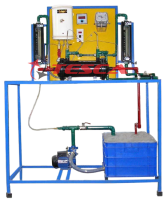

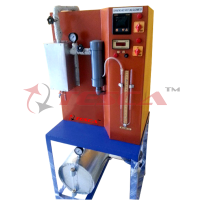

Thermal Conductivity Through Metal Bars

Order Code: 32288

Category: Thermodynamics Lab

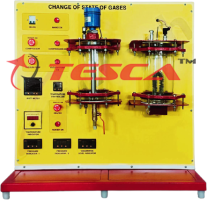

Features Mobile, compact, comprehensive, sturdy design Fully instrumentation for experimentation of air conditioning process study Direct reading of temperature, voltmeter, and ammeter measurement. Demonstrat...

SPECIFICATION

Features

- Mobile, compact, comprehensive, sturdy design

- Fully instrumentation for experimentation of air conditioning process study

- Direct reading of temperature, voltmeter, and ammeter measurement.

- Demonstration of heat transfer through composite wall apparatus.

- Fault Trainer as optional attachments

System Description

Tesca Thermal Conductivity through Metal Bars Apparatus consists of a test material bars viz. Brass & stainless steel whose one end is heated by an electrical heater and the other end is kept in a cooling water chamber which acts as heat sink. The test section i.e. intermediate of the bar is well insulated within a shell of asbestos powder to minimize the radial heat loss. Separate thermocouples have been provided to measure the radial heat loss. Two separate radial specimens with an arrangement of a central heater and ring heater to be sandwiched between them have been provided. A heat sink is provided with water circulation arrangement. This setup is properly insulated ‘Tesca’ has design the system having features of ease to operate; demonstrated & perform requisite experiments

List of Experiments

- To study the heat distribution along the length of the bar.

- To determine the thermal conductivity of given specimens.

- To Study the variation of thermal conductivity of the material with temperature.

System Components

- Water jacket – 100mm Dia x100 mm Long M.S.Pipe.

- Digital stopwatch.

- Digital Temperature Indicator with Thermocouples (0-400°C) Or RTD (PT-100) – 8 channel.

- Heater controller - Variac 2 A/Dimmer stat.

- Digital voltmeter, Ammeter.

- Base frame – Made up of ms & duly painted.

- Control Panel - for mounting of all indicators.

- Electrical switches & wiring

- Safety instrument - MCB.

- Test specimens of brass & stainless steel

- Insulating powder shell

- Heat sink

- Heaters (two types)

- Heater sinks (two types)

- Radial specimen of brass discs

- Water Pump

Optional Accessories

- Data logging software

- Provision to change the test specimen.

Operation & Maintenance Manual

- Self-explanatory operating & maintenance manual will be provided. This will include Theory, operating procedure, standard results, and maintenance procedures.

Services Required At Site

- Electric Supply 220V-240V 50Hz. With proper earthing

- Tap Water supply & drainage

91-9829132777

91-9829132777