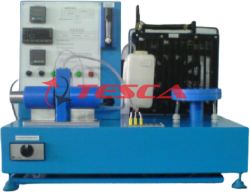

Wetted Wall Absorption Column

Order Code: 32310

Category: Thermodynamics Lab

Features Wetted wall columns may be used to determine gas/liquid mass transfer coefficients, essential when calculating the design of absorption towers. Such coefficients form the basis of correlations used to develop packed towers. Tesca Wetted Wa...

SPECIFICATION

Features

Wetted wall columns may be used to determine gas/liquid mass transfer coefficients, essential when calculating the design of absorption towers. Such coefficients form the basis of correlations used to develop packed towers.

Tesca Wetted Wall Absorption Column examines the absorption of oxygen from air into deoxygenated water (prepared by nitrogen sparging). This is an example of liquid film controlled absorption.

The liquid film mass transfer coefficient can be determined at various mass flow rates of water.

The system components are mounted within a floor standing painted steel framework. The wetted wall column is a glass column with water inlet and outlet sections and is gimbal mounted to ensure that it can be set accurately vertical.

The deoxygenating column is of similar overall size to the wetted wall column, standing vertically adjacent to it. Beside the columns is a control console housing flow meters, pump controls and oxygen analyzer. Situated between the columns are two special housings containing the oxygen analysis probes which monitor the oxygen content in the water entering and leaving the absorption column.

The apparatus uses water as the working medium, contained in a storage tank at the rear of the unit. Pumps delivering water to the deoxygenator and the absorption column are located at the base of the unit. In operation, water is sparged with nitrogen in the deoxygenator before entering the top of the wetted wall column. Air is pumped by the integral diaphragm type air pump into the base of the column. The air passes up the column, giving up the oxygen to the water. Dissolved oxygen at inlet and outlet can be measured in rapid succession. The water drains into the storage tank to be recycled to the deoxygenator.

Technical Specifications

Wetted wall column

Height: 900mm

Internal diameter: 32mm

Material: Glass Deoxygenating column Ÿ Height: 1570mm

Internal diameter: 26mm

Material: Clear acrylic

Range: 600-5,000 ml/min

Water flow meter

Range: 20-280 ml/min

Deoxygenator

Feed pump: 20 l/min @ 2m head

Absorption column feed pump: 10 l/min @ 1m head

Air feed pump: 24 l/min @ 1 kg/cm2

Sump tank capacity : Approx 40l

Oxygen Meter

Saturation

Ÿ Range: 0-199.9%

Accuracy: ± 0.5%

Resolution: 0.1%

Temperature compensation: 0-50°C automatic

Concentration

Range: 0-19.9ppm

Accuracy: ± 0.2ppm

Resolution: 0.1ppm

Temperature compensation: 0-50°C automatic

Temperature

Range: -100°C to +200°C

Accuracy: ±0.3°C

Resolution: 0.1°C

Experimental Capabilities

Calculation of liquid film mass transfer coefficients

Variation of coefficient with mass flow rate

Variation of oxygen flow rate to determine power law relationship

Calculation of liquid film mass transfer coefficients

Variation of coefficient with mass flow rate

Variation of oxygen flow rate to determine power law relationship

Services Required

Electricity Supply: Single Phase, 220 V AC, 50 Hz, 5-15 Amp. Combined socket with earth connection.

Earth voltage should be less than 5 volts.

Water Supply.

Floor Drain.

Cylinder of compressed nitrogen gas with pressure regulator (not supplied).

91-9829132777

91-9829132777