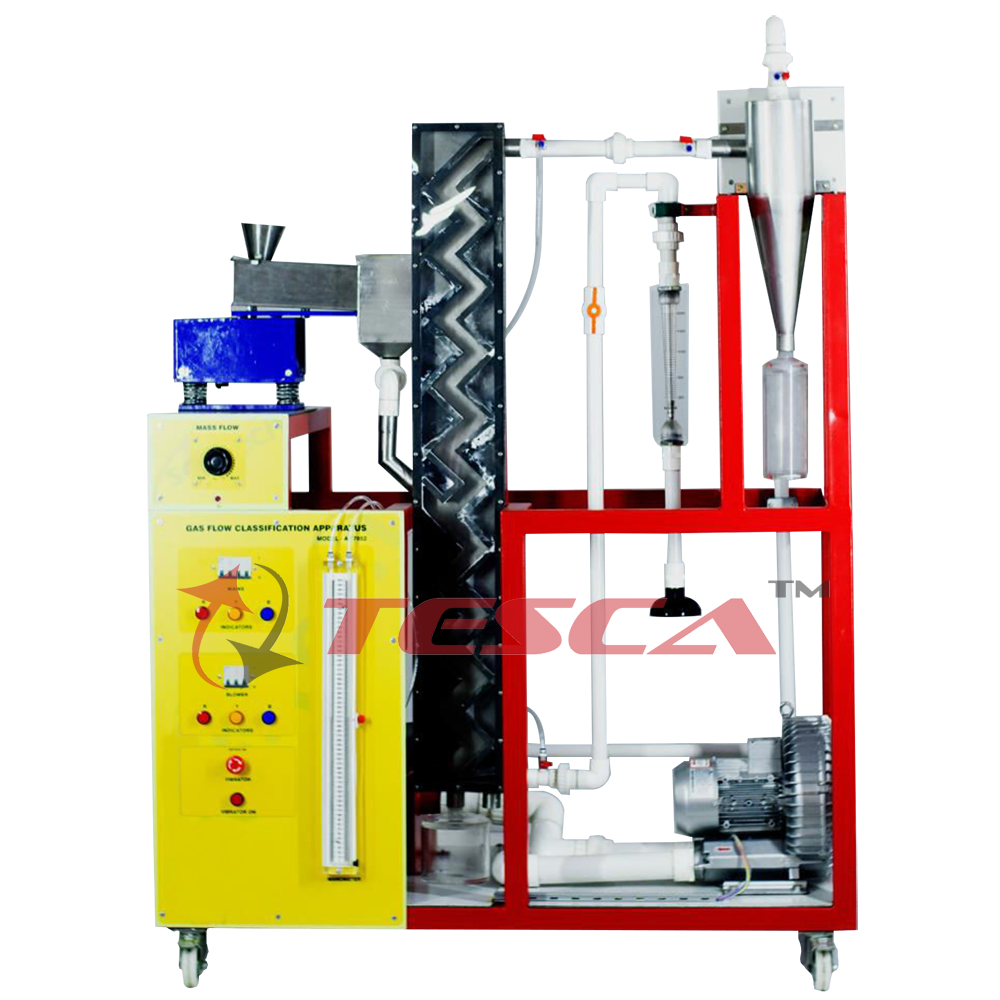

Gas Flow Classification

Order Code: 32371

Category: Thermodynamics Lab

Features Gas flow classification with a zigzag sifter Transparent duct to observe the separation process Practical experiments on a laboratory scale Zigzag sifters permit classification of solid compounds. The solid compound being separated is ...

SPECIFICATION

Features

Gas flow classification with a zigzag sifter

Transparent duct to observe the separation process

Practical experiments on a laboratory scale

Zigzag sifters permit classification of solid compounds. The solid compound being separated is charged into the feed hopper. The compound is fed into the zigzag duct of the sifter at mid-height by way of a vibrating trough. An air flow flows upwards through the vertical duct. Depending on the geometry and density of the particles, they are carried along by the air or drop down due to gravity. At every bend in the duct the solid compound passes through the air flow and falls onto the opposite wall of the sifter. This corresponds to one sifting stage. Owing to the flow conditions, a vortex wake is formed between two bends of the zigzag duct. It ensures that the solid matter moves roughly perpendicular to the air flow. In this way, a transverse sift takes place at every bend. Sequencing of large numbers of such stages results in very fine separation. Tesca Gas Flow Classification 32371 features a 20-stage zigzag duct. Transparent material provides optimum observation of the processes in the duct.

A fan generates the air flow. The volumetric air flow rate and the solid mass flow are adjustable. The fine material transported upwards with the air flow is separated by a cyclone. Pressure measurement points at the relevant positions in the trainer enable the pressure loss to be determined.

Activated carbon in different particle sizes is recommended for use as the feed material. For particle size analyses of the feed and of the coarse and fine material, a balance and a screening machine 32372 are recommended.

Specifications

Zigzag sifter to separate solid compounds

Feed hopper with vibrating trough for feed of solid compound into sifter

Dosage of feed material by way of distance of hopper outlet from vibrating trough and frequency of vibrating trough

Separation of solid compound into coarse and fine material with air flow in 20-stage zigzag duct

Air flow generation by fan; adjustment by valve

Separation of fine material from air flow by gas cyclone with tangential inlet

3 tanks for feed material and coarse and fine materials

Recording of volumetric air flow rate and differential pressure through sifter and cyclone

Technical Specifications

Vibrating trough

Mass flow: max. 10kg/h

Vibration frequency: max. 3000min-1

Zigzag sifter

Height: approx. 1500mm

Cross-sectional area: 40x50mm

Cyclone

Height: approx. 550mm

Diameter: 150mm

Fan

Volumetric flow rate: max. 600m3/h

Power consumption: approx. 3600W

Tanks

Feed hopper: 3L

Coarse material: 2L

Fine material: 2L

Measuring ranges

Cyclone and sifter differential pressures: 0…100mbar

Volumetric flow rate (air): approx. 10…100m3/h

Experiments

Learning the fundamental principle of wind sifting (gas flow classification)

Sorting

Coarse material fraction

Fine material fraction

Dependent on solid mass flow rate and volumetric air flow rate

Classifying 32372

Fraction balance

Separation function

Separation size

Sharpness of separation

Dependent on solid mass flow rate and volumetric air flow rate

Pressure losses of

Sifter

Cyclone

Dependent on solid mass flow rate and volumetric air flow rate

Requirements

Water connection 300L/h, drain

Mains Power 220 – 240V @ 50Hz, 1Ph

91-9829132777

91-9829132777