Basic Distributed Control System Trainer

Order Code: 52243

Category: Process Control Trainers

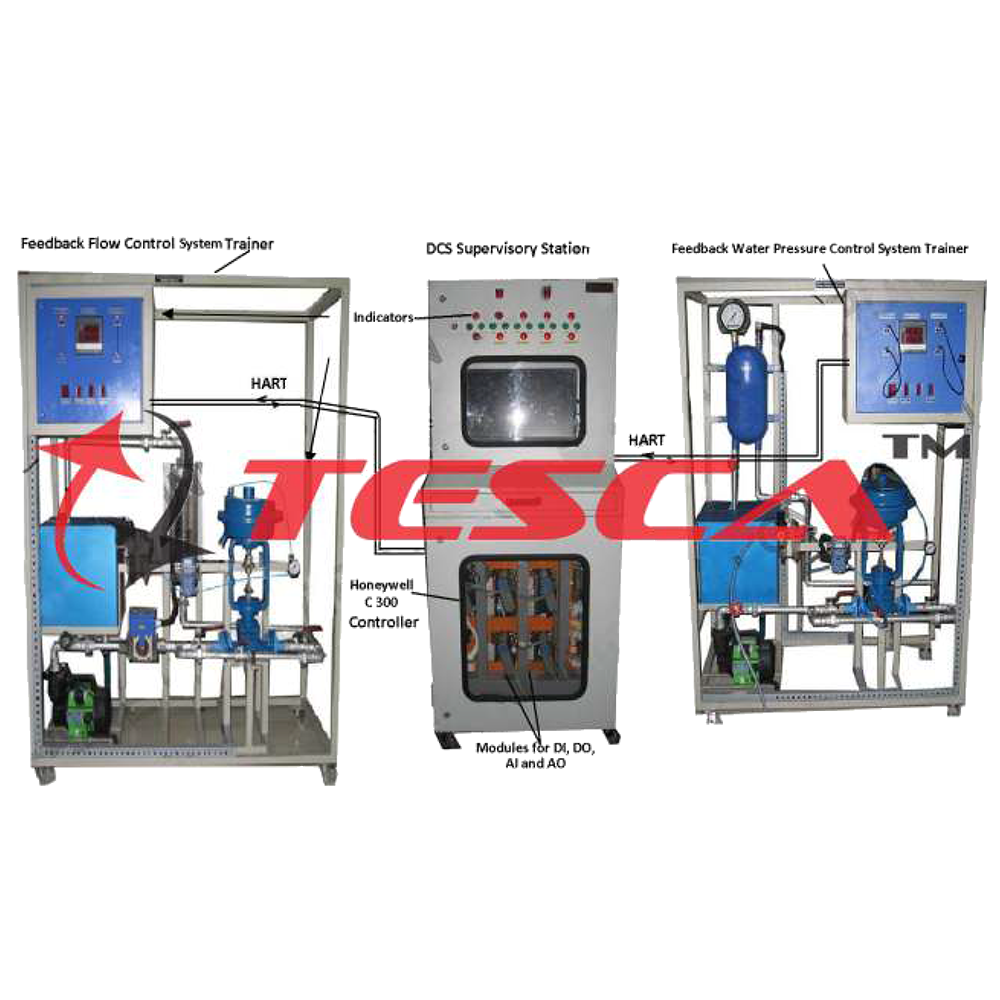

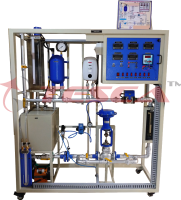

This Distributed control System Trainer outlines the principle of Distributed control System used in Industrial Environment. The SCADA software & an interfacing package, PLC /Hybrid Controller / Honeywell C 300 DCS Master Controller bas...

SPECIFICATION

This Distributed control System Trainer outlines the principle of Distributed control System used in Industrial Environment. The SCADA software & an interfacing package, PLC /Hybrid Controller / Honeywell C 300 DCS Master Controller based data logging & Distributed Control facility gives the overall idea regarding its application. Master

Controller acquires Data, Send/Receive commands to remotely placed Controllers over USB / RS 485/ Ethernet/ Modbus/ TCP-IP/HART Network. Thus Master Controller Controls Process Plants forming Distributed Control System.

KEY WORDS:

- Distributed Control System.

- PLC / Hybrid Controller/ DCS Controller (True DCS) Based Process Control Techniques.

- SCADA Based Process Control

- USB/RS 485/ Ethernet/ Modbus/ TCP-IP/HART Communication

- Process Plants such Flow-Level-Pressure-Temperaure Control Trainer shall be hooked up with DCS (Distributed Control System Trainer)

*To demonstrate proper Operation of the DCS, you will need to hook up the Supervisory Station to the below mentioned Process Control Loops

*The DCS system is supplied complete with Software, Controller, network module & I/O modules that are needed to monitor & control the process plant.

OPTIONAL LOOPS/ PROCESS PLANTS TO BE HOOKED UP WITH DISTRIBUTED CONTROL SYSTEM

*You can select any of the following Loops as per your requirement

- FLOW CONTROL SYSTEM TRAINER –52221 to 52224

- LEVEL CONTROL SYSTEM TRAINER – 52225, 52226, 52227

- WATER PRESSURE CONTROL SYSTEM TRAINER – 52228

- AIR PRESSURE CONTROL SYSTEM TRAINER – 52229

- AIR TEMPERATURE CONTROL SYSTEM TRAINER – 52230

- WATER TEMPERATURE CONTROL SYSTEM TRAINER – 52232

- CASCADE CONTROL SYSTEM TRAINER – PCST – 52231

- RATIO CONTROL SYSTEM TRAINER – PCST – 52242

RANGE OF EXPERIMENTS:

- Study of Distributed Control Systems

- Study of Proportional (P), Integral (I) and Derivative control (D) Actions.

- Study of PLC Based (52243)/ Hybrid Controller Based (52244)/ Advanced DCS Based (52245) Process Control.

- Study of operation and calibration of transmitters, I/P converter and Control Valve.

- Study of Communication Protocols such as - USB/RS 485/ Ethernet/ Modbus/ TCP-IP/HART

- Study of Individual Process Plants hooked up with the DCS.

- Study of SCADA Application Software/ Computerized Control of Process Plants.

Features:

- Understand the concept of Distributed Control System.

- User Friendly, Self Explanatory Systems.

- Explains the modern Process Control Techniques used in Industries

- Enhanced Electrical Safety Considerations.

- Training Manual & Mimic Charts for Operation Ease.

- System Frame with Caster Wheel Arrangement for ease in movement.

- M.S. powder coated cubical plant with standard Instrument Mountings.

- Inbuilt Safety Measures to avoid improper usage.

- System Dimension: 4.5 Ft. (L) X 1.5 Ft. (W) X 4.5 Ft. (H)

- Computer Interface, SCADA Application software connectivity

Services Required:

- Electric supply 230 V AC, 50 Hz.

- Clean, dry and dust free Compressed air supply 2.1 kg/cm?

91-9829132777

91-9829132777