Feedback Flow And Level Control Trainer

Order Code: 52241

Category: Process Control Trainers

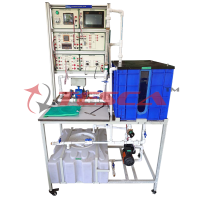

The Automated Flow and Level Control Trainer is the COMBINED system, which outlines the basics of Feedback Flow and Feedback Level Control Loops. KEY WORDS: ON-OFF & PID control. OPEN/CLOSE loop Response. MANUAL/AUTO tuning...

SPECIFICATION

The Automated Flow and Level Control Trainer is the COMBINED system, which outlines the basics of Feedback Flow and Feedback Level Control Loops.

KEY WORDS:

- ON-OFF & PID control.

- OPEN/CLOSE loop Response.

- MANUAL/AUTO tuning of controller

- Feedback Level Control.

- USB/RS 232 / Ethernet/ Modbus Communication

- Ability to hook up with DCS (Distributed Control System Trainer)

Range of experiments:

- Study of Feedback Control.

- Study of OPEN LOOP/CLOSE LOOP TUNNING & AUTO TUNNING of controller.

- Study of STEP response & Transient response of controller ( process curve).

- Study of single loop proportional (P), integral (I), and derivative (D) control.

- Study of operation and calibration of transmitters, I/P converter and pneumatic control valve.

- Study of programming and operation of PID controller.

- Study of Feedback Flow Control loop and Feedback Level Control loop.

- Study of Rotameter, capacitance type level sensor & control valve.

- Study of SCADA Application Software/ Computerized Control of Feedback Flow and Level Control System.

- Auxiliary Experiments.

Features:-

- Compact Ergonomic Design.

- User Friendly, Self Explanatory Systems.

- Leak proof Safety Measures, Sturdy Piping & Robust Construction.

- Enhanced Electrical Safety Considerations.

- Training Manuals & mimic Charts for Operation Ease.

- System Frame with Caster Wheel Arrangement for ease in movement.

- M.S. powder coated cubical plant with standard Instrument Mountings.

- Inbuilt Safety Measures to

- Computer Interface & SCADA software connectivity for analysis of Control Loop (Optional).

- Caster wheel mounted movable frame

- System Dimension: 4.5 Ft. (L) × 2 Ft. (W) × 5 Ft. (H)

- Weight: Approx. 80 Kg

Services Required:

- Electric supply 1f 230VAC, 50Hz

- Laptop/Desktop computer ( for SCADA)

- Water Supply and Drainage Arrangement

- Clean, dry Compressed air supply at 2.1 Kg/cm²

91-9829132777

91-9829132777