Cement Setting Time - Southard Viscometer

Order Code: MT205

Category: Cement, Lime Plaster & Mortar Testing

Determination on volume yield of quicklime: This IS : 6932 ( Part 6) - 1973 standard ( Part VI ) covers the methods of tests for determination of volume yield of quicklime. The Southard viscosimeter shall be used for adjusting the consi...

SPECIFICATION

Determination on volume yield of quicklime:

This IS : 6932 ( Part 6) - 1973 standard ( Part VI ) covers the methods of tests for determination of volume yield of quicklime.

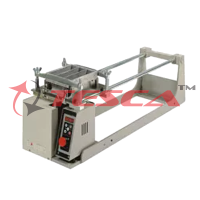

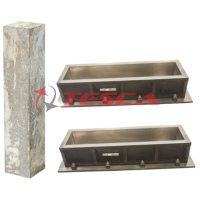

- The Southard viscosimeter shall be used for adjusting the consistency of the putty and a vessel of the shape and dimensions which shall be used for the determination of the volume yield.

- The Southard viscosimeter consists of a vertical metal cylinder 50 mm in internal diameter equipped with a tight-fitting metal piston having a working stroke of 65 mm measured from the upper open end of the cylinder.

- The piston can be raised, without rotation, by a coarse-thread screw having 2 threads/ cm passing through a nut at the lower closed end of the cylinder and engaging the piston on the lower side of the latter.

- In operation, the piston is lowered to the bottom of its stroke, the cylinder is filled carefully with the putty avoiding the inclusion of air bubbles, and the putty is struck off smooth at the top. The piston is then raised streadily by rotating the screw at the rate of one turn per second for 10 seconds, thus ejecting the contents of the cylinder vertically upwards. A metal bridge is provided to measure degree to which ejected putty out of cylinder has slumped.

- The degree to which the ejected cylinder of putty has slumped is then determined by measuring its present height by means of a metal bridge or similar device.

- For this purpose it is convenient to provide the top of the cylinder with an extended external horizontal flange with a plane surface on which the bridge may be applied.

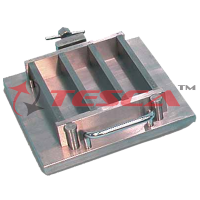

- The lime putty vessel used for determining the volume yield consists of a tinned iron cylindrical pot 63 f 1 mm in diameter with a volume of 250 ml with soldered joints and a reinforced rim of brass, the upper edge being made plane.

91-9829132777

91-9829132777