CNC Turning Center Chuck size - 165

Order Code: 54009

Category: Mechatronics/ Robotics/ CNC Lab

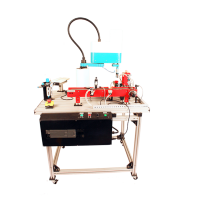

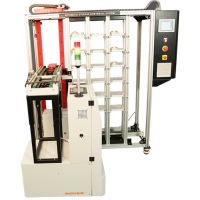

CNC Turning Centre Lathe with Industrial control, Electrical Control Box, Central Automatic Lubrication System, LM Guides for X & Z Axes, 8 Station Programmable Turret, Flood Coolant System, 3 Jaw Chuck The turning center is a 2 axis produc...

SPECIFICATION

CNC Turning Centre Lathe with Industrial control, Electrical Control Box, Central Automatic Lubrication System, LM Guides for X & Z Axes, 8 Station Programmable Turret, Flood Coolant System, 3 Jaw Chuck

- The turning center is a 2 axis production machine with 8 station programmable turret and is offered with BTP63 turret.

- The machine is built on casted base and bed and offered with industrial CNC control system. Dynamically calibrated cartridge spindle, Hydraulic Chuck and tailstock with integrated base are ideally suited for industrial production.

- The machine can be offered with FANUC / SIEMENS CNC control system.

- The 54009 can be integrated into FMS and CIM systems.

Objective

Understand the concept, components of advanced industrial machine and learn about the advanced Fanuc/Siemens/Syntec controller handling & programming skills for a turning machine to produce different kinds of components with optimized cycles and execute different kinds of practical applications simulated as exercises.

Learning Objectives:

Having successfully completed this lab, the student will demonstrate knowledge in –

- Learn about techniques to optimize the cutting parameters

- Advanced programming techniques matching industrial standards.

- Advanced machining cycles & control techniques.

- Knowledge on centralized Lubrication and re-circulating coolant system

- Learn about Intricate Tool changers system.

- Maintenance of CNC machineries and Trouble shooting

Training Skills –

- Convenient operation and Learn about advanced programming

- Identification of the Components of the CNC System

- User friendly and graphically assisted different canned cycles

- Discussion on Programming Elements

- Discussion on Industry Standard ISO G and M Codes

- Discussion on Various Tools to be used in a CNC Turning Operation

- Study on Process Planning

- Discussion on Program Zero and Offset definition

- Preparation of CNC Programs using CNC Turning Machines

- Discussion on Various Machining Cycles used in CNC Turning Programming

- General Maintenance

|

SPECIFICATIONS |

||

|

Axes |

||

|

X- axis travel |

mm |

120 |

|

Z - axis Travel |

mm |

320 |

|

Programmable feed rate |

mm/min |

0-10000 |

|

Rapid feed rate |

mm/min |

30000 |

|

Axis motor X / Z Type |

|

AC SERVO MOTOR |

|

Slides |

|

Linear Motion Guide ways |

|

CAPACITY |

||

|

Chuck size (Manual/ Hydraulic) |

mm |

165 |

|

Chuck Type |

|

Hydraulic |

|

Maximum turning Diameter |

mm |

200 |

|

Maximum turning Length |

mm |

300 |

|

Bed |

type |

45 deg Slant bed |

|

No. of axes |

no |

2 |

|

Swing over cross slide |

mm |

126 |

|

Distance between centers |

mm |

380 |

|

ACCURACY |

||

|

Positioning Accuracy |

mm |

0.01 |

|

Repeatability |

mm |

±0.005 |

|

SPINDLE |

||

|

Spindle nose taper |

|

A2-4 |

|

Bore through spindle |

mm |

40 |

|

Programmable spindle speed |

rpm |

150 – 4000 |

|

Spindle Motor Power S1 (15 minute rating in parenthesis) |

kW |

5.5 (7.5) / 3.7 (5.5)" |

|

CNC detail |

||

|

Control system |

|

"SIEMENS 828D; FANUC 0i TF” |

|

Turret |

||

|

Tool cross section |

|

20 x 20 |

|

No. of Station |

no |

8 (BTP 63) |

|

Indexing Time Adjacent Tool &180 Deg |

Sec |

0.4 / 1.4 |

|

Boring bar size(capacity) |

mm |

32 |

|

Tailstock |

||

|

Tailstock base travel |

mm |

260 |

|

Tail stroke Quill Stroke |

mm |

75 |

|

Quill Diameter |

mm |

50 |

|

Tail stroke Taper |

|

MT-4 |

|

Coolant / Lubrication |

||

|

Capacity |

L |

100/ 25 LPM |

|

Coolant motor |

kW |

0.37 |

|

Lubrication |

- |

Automatic |

|

Power source |

||

|

Power Required |

KVA |

12 |

|

Main supply (±10 %) |

|

415V, 3 Ph., 50/60 Hz |

|

Stabilizer |

|

3 phase servo type |

|

Machine dimensions |

||

|

L x W x H |

mm |

2200 x 1860 x 1900 |

|

Weight (approx) |

Kgs |

1900 |

|

Features |

||

|

Compatibility / Upgradable |

|

FMS / CIM system |

91-9829132777

91-9829132777