Warehouse Automation System. Industry 4.0 Compatible

Order Code: 54034

Category: Mechatronics/ Robotics/ CNC Lab

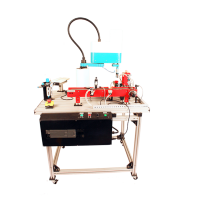

54034I - AUTOMATIC STORAGE & RETRIEVAL SYSTEM Stand-alone floor mounted system to train the concept & aspects of Material Storage & Handling. The Automatic Storage & Retrieval System is a key equipment in warehouse and material ha...

SPECIFICATION

54034I - AUTOMATIC STORAGE & RETRIEVAL SYSTEM

Stand-alone floor mounted system to train the concept & aspects of Material Storage & Handling. The Automatic

Storage & Retrieval System is a key equipment in warehouse and material handling process in factory automation. The ASRS is a programmable system that is controlled via PLC. A signal can be sent to the system, when material is required. Material is stored in pallets and the signal to the system, initiates the retrieval of a specific pallet. Further RFID integration allows customized processes to be defined for each pallet. In Smart Factory Automation, this allows different types of machining operations, inspection and assembly to take place on each pallet. The ASRS can be integrated with an AGV, transfer conveyors and vision inspection to create a warehouse automation training system. The ASRS system is an Industry 4.0 IoT ready system and can be integrated with a cloud application

- Mounting : Stand-alone floor mounted system

- : FrameFrame is built aesthetically using natural anodized aluminium profiles.

- Platform : The platform is traversed in X & Y axes by belt & AC servo motors and controlled by PLC controller

- Guides : LM Guides

- No. of storage cells : 18 (6 rows x 3 column. Option of higher storage capacity) Size of each storage rack : Rack size: 164 x 164 x 160 mm

- Pallet size: 160 x 160 x 19 mm" Max. height of component : 113 mm (110 mm + 3 mm clearance)

- X Axis Travel : Auto: 700mm (27.6 in) Manual : 1000mm (39.4 in) approx.

- Y Axis Travel : Auto: 820mm (32.3 in) Manual : 900mm (35.4 in) approx.

- Z Axis Travel : 210 mm/ 8.3 in approx.

- Load carrying capacity : Around 2 kg (4.4 lbs)

- Transfer Station : Transfer station will be provided to accept the pallet from ASRS platform or the conveyor or AGV. The transfer height is adjustable according to the height of the conveyor or AGV or Linear Slide.

- Facility for interfacing : Interfacing with Cell controller/Peripheral.

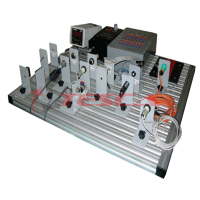

54034II - AUTOMATIC GUIDED VEHICLE

- Material handling system Integration with conveyors, Manufacturing, Assembly & ASRS.

- Guidance and routing : Guidance and Routing for Material flow Obstacle sensing and accident Prevention Load transfer through power push/pull.

- Load Carrying Capacity : 20 kgs / 44 lbs. (MAX).

- Max. Travel Speed : 20m/min or 787 in/min.

- Min turning radius : 1000mm / 40in.

Controller:

- Control : PLC Based with HMI interface

- Sensor & Guidance : Line Tracing and Color Sensing

- Drive : DC Drive

- Intermediate stations : Intermediate stations will be 6. At each station one short transfer

- conveyor will be provided to transfer the pallet. Sensors will be fitted on the no. of required stations as per the CIM layout.

91-9829132777

91-9829132777