Discontinuous Rectification

Order Code: 32368

Category: Thermodynamics Lab

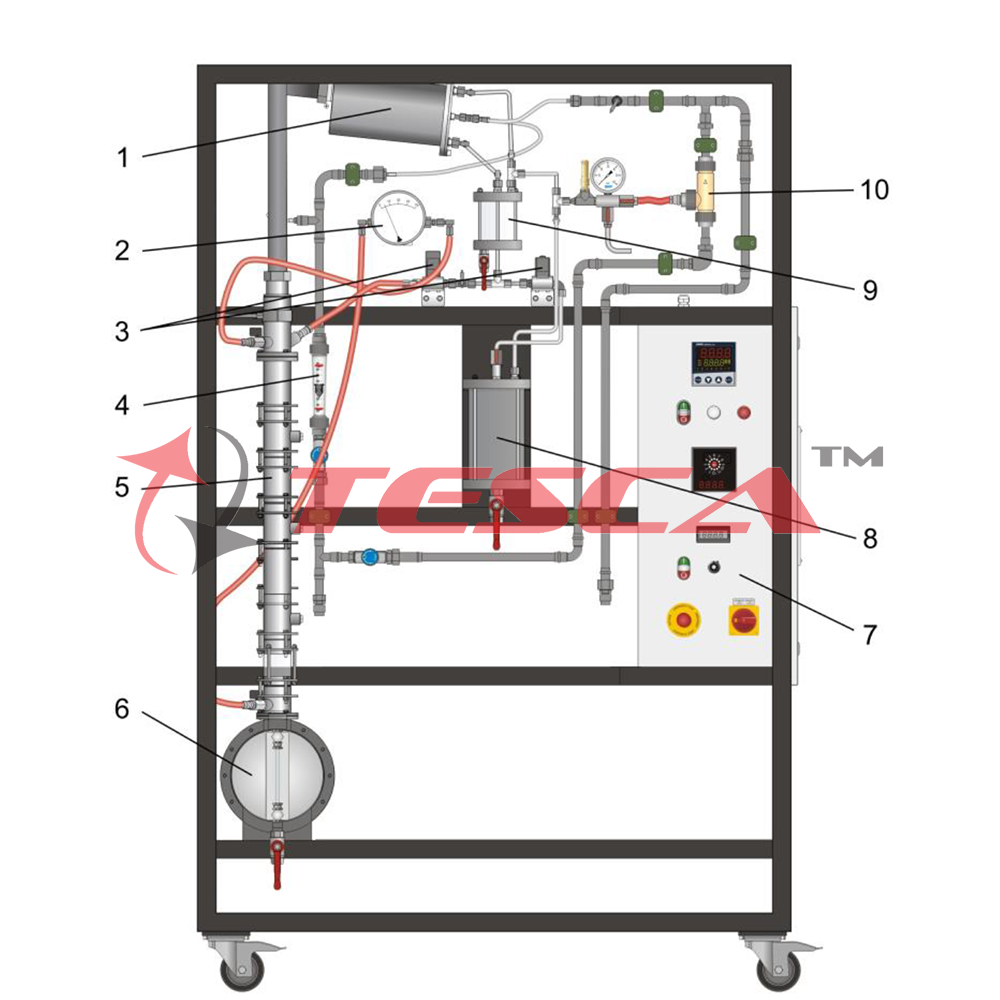

Relevant measured values are recorded by sensors and displayed digitally on the switch cabinet. The evaporator is adjusted using a PID controller. A large, clear process schematic on the switch cabinet makes it easy to assign all the process variable...

SPECIFICATION

Relevant measured values are recorded by sensors and displayed digitally on the switch cabinet. The evaporator is adjusted using a PID controller. A large, clear process schematic on the switch cabinet makes it easy to assign all the process variables. The well- structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

Features:

Discontinuous rectification1

Comparison of packed and sieve plate column1

Vacuum mode possible1

Plates in sieve plate column removable

Distillation is used to separate liquid mixtures made up of individual liquids that are soluble in one another. Rectification refers to distillation in a counter-flow. Ethanol/water is recommended as the liquid mixture for the Tesca Discontinuous Rectification 32368. The liquid mixture is added to the evaporator (bottom) tank. The mixed vapour produced moves upwards in the column. The mixed vapour contains a higher concentration of the component with the lower boiling point (ethanol). It leaves the top of the column and is condensed using a condenser and a phase separation tank. Part of the condensate is collected in a tank as product while the rest is fed back into the column. Here, on its way downwards, it undergoes further heating and material exchange with the rising mixed vapour. This exchange causes t he vapour phase to become richer in ethanol and the liquid phase to become richer in water. The liquid phase moves to the bottom where it is collected.

A sieve plate column and a packed column are available. The packed column is filled with Raschig rings. The reflux ratio is adjusted using valves.

Specifications

Discontinuous rectification with packed and sieve plate column

Interchangeable columns

Sieve plate column with 8 plates

Packed column with Raschig rings

Vacuum mode possible with water jet pump

Electrically heated evaporator

Tank for top product

Condenser and phase separation tank for top product

All tanks made of high quality glass and stainless steel

Adjustment of reflux ratio using valves

8 Temperature measuring points per column

Technical Specifications

Columns: internal diameter: 50mm, height: 765mm Water jet pump: final vacuum: approx. 200mbar

Tanks

Top product: approx. 2000mL

Phase separation: approx. 500mL

Evaporator

Power output: 0...4kW

Tank: approx. 10L

Heat transfer surface

Top product condenser: approx. 0,04m²

Measuring ranges

Temperature: 13 x 0...150°C

Reflux ratio: 0...100%

Cooling water flow rate: 30...320L/h

Column differential pressure: 0...60mbar

System pressure gauge: -1...0,6bar

Experiments

Investigation and comparison of sieve plate and packed columns

In discontinuous mode

In vacuum mode

With different reflux ratios

With different numbers of plates

Determination of concentration profiles

Determination of temperature profiles

Pressure loss over the column

Requirement

Ÿ 220-240V, 50Hz, 3 phases or 380-440V, 50Hz, 3 phases

Cold water connection: 500...1000L/h

Note: Specifications are subject to change.

Tesca Technologies Pvt. Ltd.

IT-2013, Ramchandrapura Industrial Area, Sitapura Extension,

Near Bombay Hospital, Vidhani Circle, Jaipur-302022, Rajasthan, India,

Tel: +91-141-2771791 / 2771792; Email: info@tesca.in, tesca.technologies@gmail.com Website: www.tescaglobal.com

91-9829132777

91-9829132777