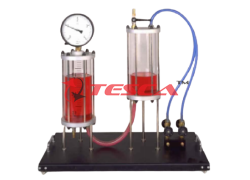

Concentric Heat Exchanger

Order Code: 32306

Category: Thermodynamics Lab

Specifications Heat Exchanger: Max. working pressure : 7 bar Max. working temperature : 80 oC Heater : 3 kW, immersion type Temperature Controller: Input : RTD or T/C Output : ON/OFF Circulation Pump: Capacity : 10 LPM @ 2m Voltage : 230 VAC S...

SPECIFICATION

Specifications

Heat Exchanger: Max. working pressure : 7 bar Max. working temperature : 80 oC

Heater : 3 kW, immersion type

Temperature Controller: Input : RTD or T/C Output

: ON/OFF

Circulation Pump: Capacity : 10 LPM @ 2m Voltage

: 230 VAC

Sump Tank: Material : stainless steel, Capacity : 30 L

Rotameters: 0.2 - 3.0 LPM, 0.5 - 5.0 LPM

Instrumentations: Temperature sensors, Flowmeter

DIGITAL INSTRUMENTATION

2 units of digital indicators

1 unit of flowmeter

1 unit of RTD sensors c/w transmitter

DATA ACQUISITION SYSTEM

An electronic signal conditioning system Stand- alone data acquisition modules Windows based data acquisition software Data Logging

Process Control

Real-Time Display

Tabulated Results

Graph of Experimental Results

Signal Analysis

Features

Parallel & Counter flow configurations can be studied in the same unit using valves.

Requires only cold water supply for experimentation.

Data Acquisition System with sensors & software included.

Tesca Concentric Heat Exchanger consists of a concentric tube exchanger in the form of “U”, mounted on a support frame. The external surface of the exchanger is insulated. Six temperature sensors are installed in both the inlet and outlet tubes, to measure the fluid temperatures accurately. To minimize losses in the system, the hot water is fed through the inner pipe, with the cooling water in the outer annulus. Control valves are incorporated in each of the two streams to regulate the flow. The flow rates are measured using independent flow meters installed in each line.

Temperature and flow readings could continuously be captured and logged into the computer with a data Acquisition System. These data are useful for further calculations and analysis. On-line trending displays allow students to observe the fluctuations of flow and temperature readings immediately. Detailed Operation & Maintenance Manual is provided along with the trainer.

Experimental Capabilities:

Energy balance determination

Temperature profiles in co- and counter-current flows

Log mean temperature difference

Heat transfer coefficient calculation

Effect of flow rate on heat transfer rate

Heat loss estimation and „k-factors?.

Required Services:

Electric Supply 230 V AC, 16 A, Single Phase, Earthed.

Water Supply: Cold tap water supply & Drainage

91-9829132777

91-9829132777