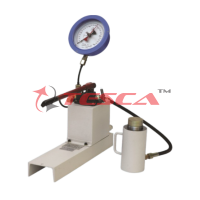

Flexural Testing Machine Automatic Pace Rate Controlled Accessories for Compression Testing Machine

Order Code: MT034

Category: Concrete Testing

As per IS:516, BS:1881 and ASTM C78, EN 12390-5, AASHTO T22, Fully automatic test execution. Controllable pace rate from 0.03 KN/Sec to 10 KN/Sec Automatic Test Execution: Once the machine has been switched on, the specimen positioned and centere...

SPECIFICATION

As per IS:516, BS:1881 and ASTM C78, EN 12390-5, AASHTO T22, Fully automatic test execution. Controllable pace rate from 0.03 KN/Sec to 10 KN/Sec

Automatic Test Execution:

Once the machine has been switched on, the specimen positioned and centered, the only required operations are

Set test parameters ? including load rate:

- Press the start button

- Tighten the pressure valve

- The machine automatically: starts the rapid approach; switches to the test speed once the specimen comes into contact with the upper platen; automatically stops the motor upon specimen failure

- Release the pressure valve

- The test execution conforming to Standards can be easily proved.

- Working on 240V, 50?60Hz, single phase.

- Dual stage pump assuring fast piston approach and precise test execution

- Test execution conforming to EN 12390?4, ASTM C39, AASHTO T22

- Controllable pace rate from 1 KN/Sec to 10 KN/Sec.

- Auto stop after completion of each test.

- Soft platen?to?specimen contact and smooth load rate control from the very beginning of the ramp

Frame:

- Four column high stiffness welded frame tested for stability.

- Heavy duty spherical seat , allowing initial free alignment at the initial contact with the specimen and automatic jamming up to the end of test.

- Surface hardness of platen is 55 HRC, flatness tolerance 0.03 mm. Traceable certificate of surface hardness available on request.

- Piston travel limit switch (Extra cost)

- Emergency stop button

Salient features of data manager PC software (Optional at extra cost.):

- Two way communication i.e machine operates from computer and from the touch screen controller both (Stat, stop, save data and save graph)

- Results directly saved in excel file

- Graph also saved in excel file

- Capable to save customer name, other details of customer, ageing of cube moulds, identification mark of the cube mould, date and time of testing

- Capable to print direct report from the computer

- Capable to select different test perameters like pace rate, sample size and area from the computer (software)

Overall Dimensions : 430 X 760 X 1150 (L X W X D) mm

Net weight (in kg) : 225 kg

Note: It is recommended to use the machine with 3 KVA servo stabilizer

91-9829132777

91-9829132777