Kaplan Turbine Trainer

Order Code: 32031

Category: Fluid Mechanics Lab

Kaplan Turbine is an axial flow reaction turbine named in honour of Dr. B. Kaplan, a German Engineer. Tesca Kaplan Turbine Test Rig is suitable for low head. The power produced by a turbine is proportional to QH. As the head (H) decreases the J di...

SPECIFICATION

Kaplan Turbine is an axial flow reaction turbine named in honour of Dr. B. Kaplan, a German Engineer.

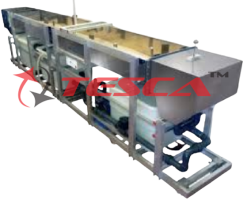

Tesca Kaplan Turbine Test Rig is suitable for low head. The power produced by a turbine is proportional to QH. As the head (H) decreases the J discharge (Q) must increase to produce the same power. The present set-up consists of a scroll casing housing a runner. Water enters the turbine through the stationary guide vanes and passes through the runner axially. The runner has a hub and airfoil vanes, which are mounted on it.

The water is fed to the turbine by means of Centrifugal Pump. The runner is directly mounted on one end of a central SS shaft and the other end is connected to a brake arrangement. A transparent hollow cylinder made of acrylic is fitted in between the draft tube and the casing for observation of flow. Load is applied to the turbine with the help of rope brake arrangement so that the efficiency of the turbine can be calculated. The set-up is supplied with a control panel. A draft tube is fitted on the outlet of the turbine.

The set-up is complete with a guide mechanism. Pressure and Vacuum gauges are fitted at the inlet and outlet of the turbine to measure the total supply head on the turbine Tesca Kaplan Turbine Test Rig is designed to show the operation & performance characteristics of Kaplan Turbine. A vertical shaft Kaplan Turbine to develop 5 HP at 1500 rpm, rope brake arrangement

Structural Specifications:

Stainless structure.

Screws, nuts, plates and all the metallic elements in stainless steel.

Diagram in the front panel with similar distribution to the elements in the real unit.

Quick connections for adaptation to feed hydraulics sources.

Technical Data:

(A) Demonstration Test Rig:

Functional model of a Kaplan turbine, with a ring of wicket gates that allows to control the water flow in the turbine.

Speed range: 0 – 2500 r.p.m. Number of blades of the turbine: 4. Diameter of the turbine: 52 mm.

Number of wicket gates of the ring: 8.

Braking system:

Band brake.

Adjustable braking tension.

Radius of the pulley of the brake: 50 x 10-3 m. Transparent water tank, capacity: 120 l. approx. Instrumentation and sensors:

2 Water pressure sensors, range: 0 - 100 PSI. Force sensor (load cell), range: 0 - 20 N.

Slot sensor to measure the speed, range: 0-20000 r.p.m.

Water flow sensor, range: 2 - 150 l./min.

Water pump:

Maximum height: 20 m. Maximum pressure: 2.2 bar. Maximum water flow: 160 l./min. Power: 0.5 kW.

Speed adjustable through variable-speed drive.

(B) 1KW Test Rig Structural Specifications Stainless structure.

Screws, nuts, plates and all the metallic elements in stainless steel.

Diagram in the front panel with similar distribution to the elements in the real unit.

Quick connections for adaptation to feed hydraulics source.

KAPLAN TURBINE TEST RIG (1 KW) (CC System).

a) Kaplan Turbine designed for laboratory experimental purpose & to conduct tests under constant head of the following specifications.

Net Head: 5 m. Discharge: 1500 LPM.

Normal Speed: 1000 RPM. Power : 1 Kw

Brake Drum Dia.: 300 mm.

Spiral Casing: Of close grained cast iron, with 150 mm flanged inlet.

Guide Vane Assembly: Stainless steel guide Vanes coast integral with their spindles with external link mechanism, which can be operated by means of a hand wheel.

Runner: Of gun metal with polished adjustable aerofoil blades for efficient operations. The blades can be adjustable by means of a suitable area link mechanism

housed inside the runner hub, operating through the hollow steel shaft.

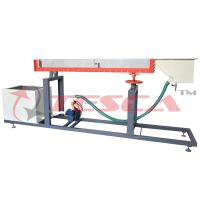

Brake Arrangement: Consists of a cast iron brake drum machined & polished, cooling water supply pipe from the turbine inlet, internal scoop, discharge pipe, spring balance rope brake & loading dead weights.

b) Pump with volute casing suitable for the supply of water for the Turbine size of 6” to discharge 1500 LPM at a total head of 8 m. coupled to 7.5 HP induction motor 3 phase 400/440 V AC. supply

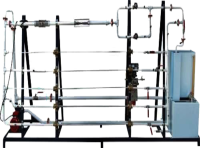

c) Flow measuring Unit: A C.I orifice meter of 150 mm dia. (6”) size with double column differential manometer (With out Mercury) on a panel board to measure the difference of pressure.

d) Reservoir of size 1.75 m length x 0.9 m width x 0.65 m. height with drain valve of ½ ” size & a bend.

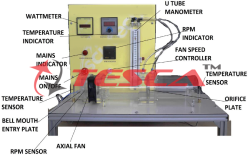

e) Starter, Switch, Digital speed indicator, Pipe line with control valve

f) Strong iron stand to support the unit.

Experiments:

1. Study of construction of Kaplan turbine

2. Determination constant head charac- teristics curve

3. Determination of constant speed characteristics curves.

4. Determination of constant efficiency curves.

COMPUTERIZATION (optional)

‘Sci-cal’ Software & Interface: ‘Tesca’ software, interface & related sensors enable plotting of required graphs through the formulae integrated into software. The students can carry out experiments and see graphs and results in ‘Labview’.

Depending on the measurement method, the measured values can be read off the analogue manometer or digital displays. The measured values are transmitted directly to a PC via USB. The data acquisition software is included.

1. Data Acquisition with high performance, various function parameters IP & OP.

2. L o w c o s t , P o r t a b l e , c o m p a c t , comprehensive, sturdy design

3. Fully instrumentation for experimentation of data acquisition of different parameters of refrigeration system & its calculations.

4. Direct reading of parameters like temperature, pressures, load and power measurement.

5. Very high -speed dynamic signal acquisition is possible.

6. Computerized Load control attachment as optional accessories.

System has the unique feature of direct reading & automatic calculating all efficiency & heat balance sheets of the system. The online graphical representation of important parameters is displayed on screen to see the effect of change in load. Final results & graphs are built available in software. System has facilities of measuring parameters like temperature at different locations, pressures, load, mass flow of refrigeration (Rotameter) and power measurement.

Windows based software is supplied with the CAPTURE range of equipment offering a complete teaching package of coursework and laboratory investigation.

The familiar Windows environment allows the student to explore the principles of each machine quickly and easily, highlighting the difference between theoretical and practical measurements, thus providing a good understanding of the principles involved.

This software runs under Windows operating systems and has been designed for maximum flexibility and ease of use. Comprehensive ‘Help’ screens guide the student through both the theoretical background and the practical investigation of the machine under examination. Suggested laboratory investigations and further questions for the student to answer are included in the software, together with all the information required to set up and run the teaching exercises.

SOFTWARE CAPABILITIES

This software includes a range of functions and capabilities designed to make the operation of the equipment and processing of the results more straightforward, and also to enhance student understanding of the subjects being covered.

It includes:

Diagrammatic representation of the equipment, complete with real time display of the various sensor outputs

Presentation screens, giving an overview of the software, the equipment, the procedure and associated theory

Detailed ‘Help’ facilities giving in depth guidance

Automatic data logging of sensor values into a spreadsheet format

Control over sampling intervals

Student questions and answers, including a layered ‘Hint’ facility

Processing of sampled values (this may be linked to the questions and answers to ensure student understanding)

Sophisticated graph plotting facilities of both measured and calculated values, including comparisons taken under different conditions

Export of data to Microsoft Excel or other spreadsheets

Links to user defined word processor

Calibration facility for sensors

Real time bar graph display of sensor outputs

Recent history graphical display

TECHNICAL DETAILS

The analogue output data is digitized and transferred to a computer using the standard USB (Universal Serial Bus). This allows any standard modern Windows computer to be used, including notebooks, and does not require any internal access to the computer.

The equipment is supplied complete with a USB lead for connection to the computer. The 32017 Turbine Demonstration Unit interfaces to the computer via the provided devices and the USB port of the computer.

Also available is a software driver that allows the outputs to be read in other software programs, such as Labview.

OPTIONAL ACCESSORIES:

1. VFD

2. Digital tachometer

3. Data acquisition system (computerization) stop watch

Manuals:

This module will be supplied with the following manuals:

1. Required services manual.

2. Assembly and installation manual.

3. Interface and control software manual (if opted for).

4. Starting-up manual.

5. Safety manual.

6. Maintenance manual.

7. Calibration manual (if it is necessary).

8. Practices manual.

91-9829132777

91-9829132777