Nozzle Performance Study Apparatus

Order Code: 32052

Category: Fluid Mechanics Lab

Features: 1. Pressure distribution in convergent and divergent nozzles 2. Three nozzles with different contours 3. Speed of sound and shock wave Convergent nozzles are used in the subsonic range. Velocities in the supersonic range can be achieved...

SPECIFICATION

Features:

1. Pressure distribution in convergent and divergent nozzles

2. Three nozzles with different contours

3. Speed of sound and shock wave

Convergent nozzles are used in the subsonic range. Velocities in the supersonic range can be achieved in de Laval nozzles; their nozzle geometry is a combination of convergent and divergent contours. De Laval nozzles are used in supersonic wind tunnels, steam turbines, jet engines, and rocket technology. Pressure curves are a good way of representing the different velocity ranges in the nozzle, such as subsonic, supersonic, and shock waves. The experimental unit 32052 is used to measure pressure curves in convergent and convergent-divergent nozzles (de Laval nozzles) and to study the actual flow of compressible fluids. In addition, the "choking effect" is demonstrated, where the mass flow rate stops increasing upon reaching the critical pressure ratio. Air is used as a compressible fluid.

In the experiment, the air flows through a nozzle and is thus accelerated. The pressure curve is recorded in the direction of flow over several measuring points. The air pressure upstream and downstream of the nozzle can be adjusted.

Three interchangeable nozzles are available to study the pressure and velocity ratios: one convergent contour and two de Laval nozzles with different length nozzle extensions.

The measured values for temperatures, pressures, and mass flow rate are recorded. The well-structured instructional material sets out the fundamentals and provides a step-by-step guide through the experiments.

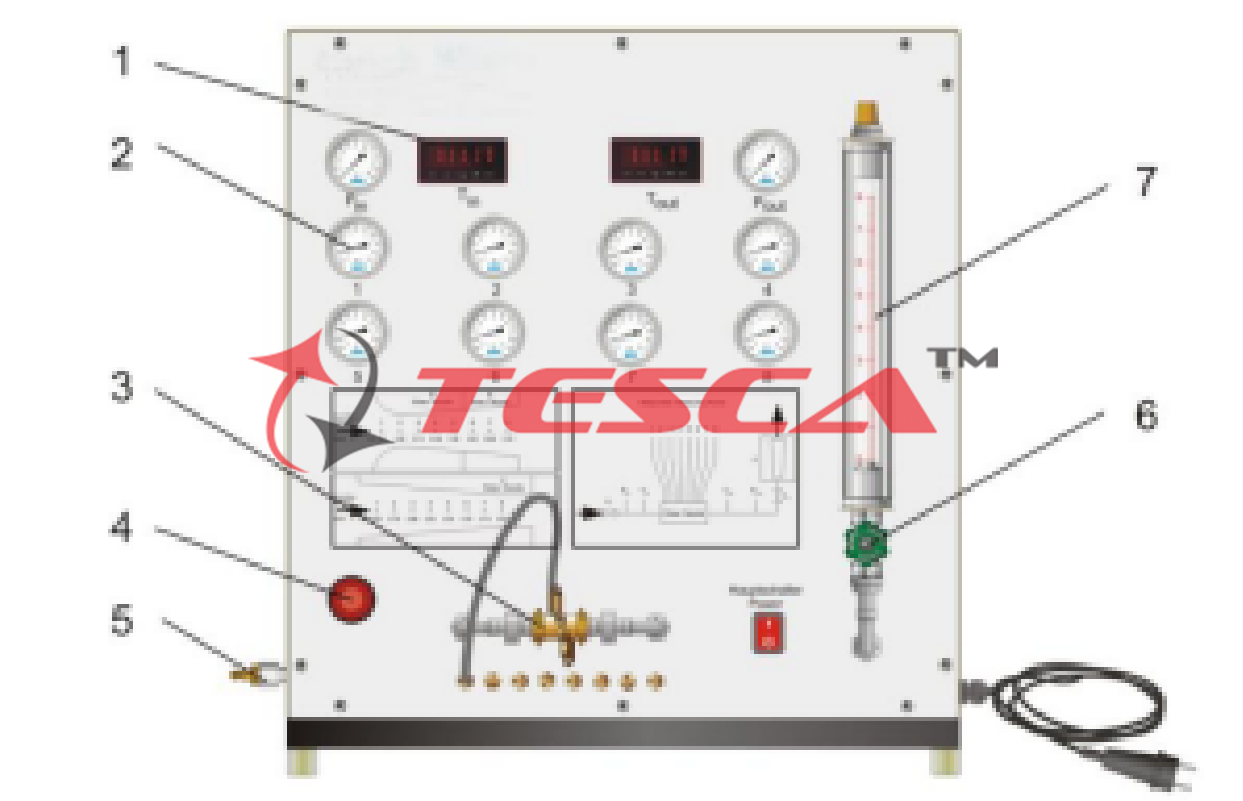

Specifications:

1. Nozzle pressure distribution in the actual flow of compressible fluids

2. Three nozzles with pressure measurement points: 1 convergent nozzle, 1 short and 1 long de Laval nozzle

3. Compressed air regulator for adjusting the pressure downstream of the nozzle

4. Needle valve on the flow meter for adjusting the backpressure

5. Instruments: manometer and digital temperature display upstream and downstream of the nozzle as well as a rota meter

Technical Specifications:

Air consumption of the experimental unit

Compressed air: max. 10bar

Air consumption: approx. 5g/s 3 nozzles, brass

1 x de Laval nozzle, short nozzle extension

1 x de Laval nozzle, long nozzle extension

1 x convergent nozzle

Compressed air regulator

Control range: 0...8,6bar Measuring ranges

Temperature: 0...100°C

Pressure: 2x 0...10bar, 8x 1...9bar

Mass flow rate: 0,7...8,3g/s

Requirements:

Mains Supply: 230V, 50Hz, 1 phase

Compressed air connection max. 10bar, 250NL/min

91-9829132777

91-9829132777