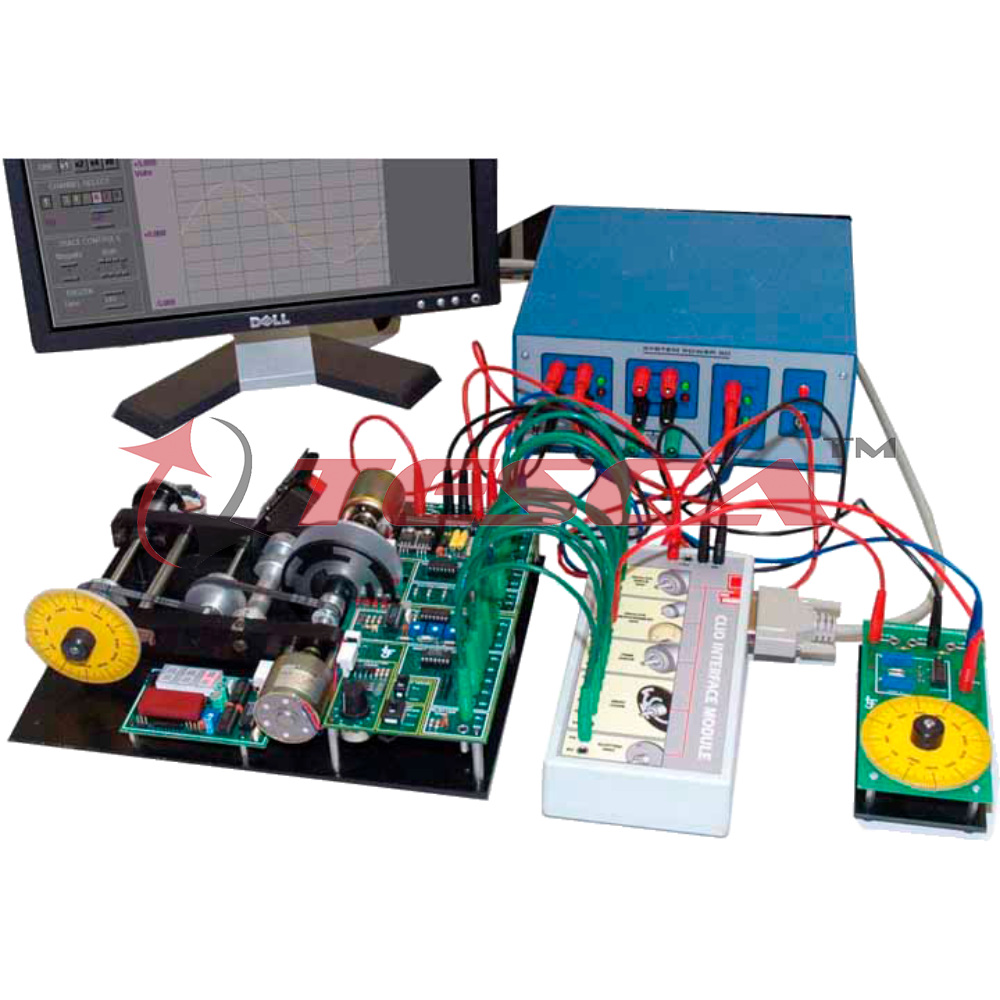

PC Based Analog & Digital Motor Control Trainer

Order Code: 52053

Category: Instrumentation Trainers

Introduction: Control systems are at the very heart of the technology-based world in which we live. As we grow increasingly reliant on the technology, we will depend to greater extent on the services of maintenance / repair engineers and techni...

SPECIFICATION

Introduction:

Control systems are at the very heart of the technology-based world in which we live. As we grow increasingly reliant on the technology, we will depend to greater extent on the services of maintenance / repair engineers and technicians. The proposed Motor control trainer offers a progressive hand on approach to teaching control technology. The Motor control trainer has three levels of study, each level is based on a teaching set of control modules. Starting with basic practical introduction to analog control, advanced analog control using three-term controller and Digital control based on a Microprocessor system. The unit has an electro-mechanical unit containing an iron-less rotor DC motor, Analog & digital motor drive circuitry, 3 position Eddy current brake & sensors for speed and position.Virtual Control System Lab software is included in the system to perform all the experiments, so that dynamic results can be seen on PC , stored and analyzed.

Topics Covered :

Control systems are at the very heart of the technology-based world in which we live. As we grow increasingly reliant on the technology, we will depend to greater extent on the services of maintenance / repair engineers and technicians. The proposed Motor control trainer offers a progressive hand on approach to teaching control technology. The Motor control trainer has three levels of study, each level is based on a teaching set of control modules. Starting with basic practical introduction to analog control, advanced analog control using three-term controller and Digital control based on a Microprocessor system. The unit has an electro-mechanical unit containing an iron-less rotor DC motor, Analog & digital motor drive circuitry, 3 position Eddy current brake & sensors for speed and position.Virtual Control System Lab software is included in the system to perform all the experiments, so that dynamic results can be seen on PC , stored and analyzed.

Topics Covered :

- Analog control – an overview

- Describing and identifying system behaviour

- Time and frequency response

- Principles of feedback

- Proportional position control

- Behaviour of second order systems

- Position control with velocity feedback

- 3-Term or PID control

- Stability

- The use of computers for control

- Analog and digital interfacing

- Direct digital control

Technical Specifications :

The Analog and Digital Motor control training system consist of following modules;

DC motor control Module - DCMC

Features of the DC motor control includes:

- DC motor with on-board drive circuitry.

- Angular position indication disc, calibrated in degrees.

- Tacho-generator with switchable load resistor.

- Continuous rotation potentiometer.

- Gray-coded disc and slotted disc.

- Digital tachometer with r.p.m. readout.

- Three-position eddy current brake.

Command potentiometer module - COMPOT

The Command potentiometer provides a manually generated command signal to the control system. The calibrated indicator disc be provides an angular position indication in degrees.

When used in conjunction with a Windows TM based PC, the Simulated control laboratory performs the following functions simultaneously:

The Command potentiometer provides a manually generated command signal to the control system. The calibrated indicator disc be provides an angular position indication in degrees.

When used in conjunction with a Windows TM based PC, the Simulated control laboratory performs the following functions simultaneously:

- Monitors the reference signal from the Command potentiometer.

- Provides a PID controller with adjustable parameters.

- Generates analog/digital signals to control the DC motor module.

- Responds to analog/digital feedback signals from the DC motor module.

- Displays all control and feedback signals on the PC screen.

Simulated Control Laboratory Software - SCLS

The Virtual control laboratory software is a comprehensive teaching package that is designed specifically for use with the motor control modules.

The main screen of the Virtual control laboratory software should be divided into four sections, viz. Control reference (input) signal, Controller, Plant & Display. Each of these may be configured independently by the user:

The Virtual control laboratory software is a comprehensive teaching package that is designed specifically for use with the motor control modules.

The main screen of the Virtual control laboratory software should be divided into four sections, viz. Control reference (input) signal, Controller, Plant & Display. Each of these may be configured independently by the user:

PC Interface module:

The PC Interface Module is designed to connect directly to the parallel port of a PC via the cable supplied. The sockets on the Interface module allow direct connection to the inputs and outputs of the DC motor module and Command potentiometer, via 4mm leads. The PC interface module is powered from the same power supply as the DC motor module.

The PC Interface Module is designed to connect directly to the parallel port of a PC via the cable supplied. The sockets on the Interface module allow direct connection to the inputs and outputs of the DC motor module and Command potentiometer, via 4mm leads. The PC interface module is powered from the same power supply as the DC motor module.

Set of 36 x 4MM Interconnection Leads :

This set features lead that comprise high quality multi strand wire & terminated with a 4mm plug at each end.

This set features lead that comprise high quality multi strand wire & terminated with a 4mm plug at each end.

91-9829132777

91-9829132777