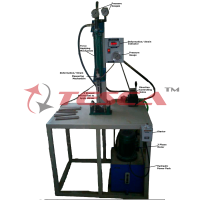

PLC Based Bottle Filling Plant Module

Order Code: 52246

Category: Process Control Trainers

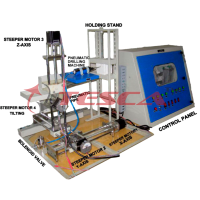

The PLC based Linear Bottle Filling Plant gives an idea regarding usage of Programmable Logic Controllers in industrial application. Features Compact Ergonomic Design. User Friendly, Self Explanatory Systems. Leak proof Safety ...

SPECIFICATION

The PLC based Linear Bottle Filling Plant gives an idea regarding usage of Programmable Logic Controllers in industrial application.

Features

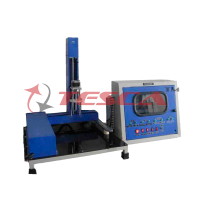

- Compact Ergonomic Design.

- User Friendly, Self Explanatory Systems.

- Leak proof Safety Measures, sturdy piping & Robust Construction.

- Enhanced Electrical Safety Considerations.

- Training Manuals & mimic Charts for Operation Ease.

- M.S. powder coated cubical plant with standard Instrument Mountings.

- Inbuilt Safety Measures to avoid improper usage.

- Computer Interface (Optional).

- PLC with 8 DI/DO & PC-PLC communication cable (Optional), standard Program.

Range of experiments

- Study of PLC programming.

- Demonstration of bottle filling plant

- Study of application of solenoid valve, level switches and proximity switches.

System Components:

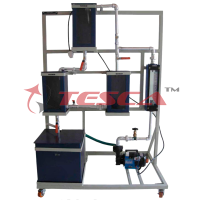

- Conveyor system with motor for movement of bottle.

- Proximity sensor for sensing bottle positions.

- Liquid filling Operation.

- Solenoid valve for control of liquid filling.

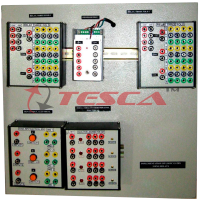

- Control panel for visual indication of process.

- Computerized control system trainer (optional).

- System Dimension- 4.5 Ft. (L) X 1 Ft. (W) X 2 Ft. (H)

- Bottle count operation.

Services Required:

- Electric Supply of 1f 230 VAC

- Water supply and drainage arrangement

91-9829132777

91-9829132777