Temperature Control Trainer (water)

Order Code: 52231

Category: Process Control Trainers

The Water Temperature Control Trainer is the system, which outlines the basics of Closed Loop Water Temperature Control and various aspects related to it. KEY WORDS: Feedback Water Temperature Control. PID control. SCADA B...

SPECIFICATION

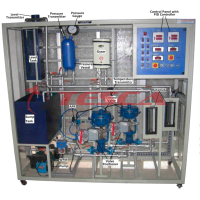

The Water Temperature Control Trainer is the system, which outlines the basics of Closed Loop Water Temperature Control and various aspects related to it.

KEY WORDS:

- Feedback Water Temperature Control.

- PID control.

- SCADA Based Water Temperature Control

- P, P I, P I D Controller Action.

- USB / Ethernet / RS232 / RS 485/ Modbus Communication

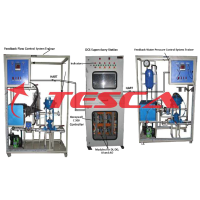

- Ability to hook up with DCS (Distributed Control System Trainer)

Range of experiments:

- Study of single loop proportional, integral and derivative control.

- Study of operation and calibration of sensors/transmitter.

- Study of stability of single loop control.

- Configure micro controller based PID to give manual output, change controller mode as Manual or Auto, give ON-OFF, proportional, integral, derivative PI and PID Control, change local set point, configure and run a set point ramp, configure measured values to either percentage or temp. Demonstrate the proportional control of

- temperature, with offset, overshoot, Instability optimum value of proportional band or gain.

- Demonstrate the use of RTD (or a transmitter) for the measurement of temperature of water. Show the operation of a thyristor to control the energy input of an electrical heater.

- Demonstrate the effect of integral control and the optimization of the integral (reset) time for temperature control.

- Optimize the parameters for PID control of temperature; demonstrate the use of automatic tuning.

- Study of SCADA Application Software/ Computerized Control of Water Temperature Control System Control System. (Optional)

Features:

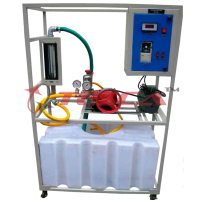

- Compact Ergonomic Design.

- User Friendly, Self Explanatory Systems.

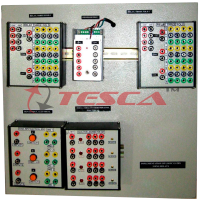

- Electrical control panel.

- Enhanced Electrical Safety Considerations.

- Training Manual, mimic Charts for Operation Ease.

- Inbuilt Safety Measures to avoid improper usage.

- Computer Interface & SCADA software connectivity for analysis of Temperature Control System Trainer (Optional).

- Caster wheel mounted movable frame

- System Dimension: 4 Ft. (L) X 1.5 Ft. (W) X 4 Ft. (H)

Services Required:

- Water supply and drainage arrangement.

- Electric supply 1φ 230 V AC, 50 Hz.

91-9829132777

91-9829132777